Understanding the Efficiency of Motors

According to the U.S. Department of Energy (DOE), electric-motor-driven equipment uses 25 percent of all of the electricity consumed in the United States. With premium-efficiency motors with adjustable-speed drives, significant electricity savings are possible.

HISTORY OF PREMIUM EFFICIENCY IN THE UNITED STATES

During the early 1980s, several manufacturers introduced “premium”-efficiency motors, which used better lamination material, more active material (laminations and copper), and lower-loss cooling fans. But there were no guidelines as to the efficiency a motor needed to produce to be considered “high-efficiency.”

The National Electrical Manufacturers Association (NEMA) first made a distinction between standard and energy-efficient motors with the 1990 revision of its MG 1-1987 standard, which would become the standard for the Energy Policy Act of 1992 (EPAct). In October 1997, the EPAct took effect, mandating minimum energy-performance standards (MEPS) for 1- to 200-hp (0.75 to 150 kw) two-, four-, and six-pole general-purpose totally enclosed fan-cooled (TEFC) and open-drip-proof (ODP) foot-mounted motors. This required that any EPAct motor manufactured for sale in the United States comply with minimum nominal-efficiency, testing, and labeling standards. The EPAct does not cover “special-purpose” motors, such as footless motors with C-faces, or close-coupled pump mountings.

The Consortium for Energy Efficiency (CEE) established “premium”-efficiency guidelines that were used by many utilities for rebate programs in 1996. By August 2001, NEMA and CEE harmonized their efficiency standards, establishing NEMA Premium efficiency standards for 1- to 500-hp (0.75 to 370 kw) two-, four-, and six-pole low- and medium-voltage TEFC and ODP motors. The NEMA Premium standard first defined in NEMA MG 1-1998, Revision 2, does not differentiate between mounting configurations, and all types of motors are covered.

EPAct 2005 mandates that the U.S. government purchase NEMA Premium motors per the Federal Energy Management Program (FEMP) (www1.eere.energy.gov/femp/procurement).

EFFICIENCY OUTSIDE OF THE UNITED STATES

The European Union (EU) and European Committee of Manufacturers of Electrical Machines and Power Electronics (CEMEP) have developed a voluntary efficiency-classification scheme for motors in the 1.1-to-75-kw range. “Eff1” designates the highest-efficiency motors, comparable to U.S. EPAct motors, while “Eff2” designates standard-efficiency motors, and “Eff3” designates motors the EU is encouraging manufacturers to discontinue. Discussions to set MEPS, as the United States has done with the EPAct, are under way.

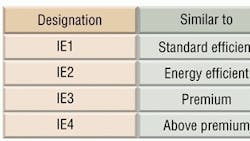

In 2005, Paulo Bertoldi of the European Commission Joint Research Centre initiated Standards for Energy Efficiency of Electric Motor Systems (SEEEM) with the goal of establishing global performance standards and testing methodology. As of 2008, motor test standards had been harmonized between Institute of Electrical and Electronics Engineers (IEEE) 112b, Canadian Standards Association (CSA) 390, and International Electrotechnical Commission (IEC) 60034-2-1. These new efficiency designations are scheduled to replace the CEMEP Eff markings in April 2009. Efficiency standards still differ between NEMA and IEC, but work continues. IEC 60034-30 specifies new efficiency levels for motors (Table 1).

Because of the design of IEC motors, manufacturers have difficulty reaching efficiencies higher than IE2 without significant electrical redesign and/or the use of larger frames. IE3 is not supported by leading European manufacturers because of the high costs of retooling. CEMEP agrees with the EU measure to adopt IE2 as an MEPS in 2011. A proposal to increase efficiency using IE2 motors with adjustable-speed drives is being studied. IE3 would become a “self-regulation of the class IE3, which means the industry commits itself on a voluntary basis to develop, launch, and monitor IE3 motors on the market.”1

IE4 efficiency is likely to be from a technology other than an AC induction motor, such as a permanent-magnet rotor or a switched-reluctance motor, both of which require a drive for operation. This is likely the case in the United States for motors above NEMA Premium efficiency.

MEPS for IEC motors is a relatively new concept. Currently, there are no mandatory motor-efficiency standards for Europe, but talks indicate they may be adopted by 2012. MEPS have existed for many years in Australia and New Zealand. AS/NZS 1359.5:2000 has raised minimum motor efficiency to the equivalent of U.S. EPAct motor efficiency. Table 2 shows the global usage of MEPS.

ENERGY INDEPENDENCE AND SECURITY ACT OF 2007

The Energy Independence and Security Act of 2007 (EISA), which will take effect for products produced after Dec. 19, 2010, will require the use of premium-efficiency motors for most commercial applications and mandate minimum performance standards for HVAC units.

Proposed changes include the addition of seven product categories to meet MG 1, Table 12-11 (energy-efficient levels), and making 1-to-200-hp covered product meet NEMA Premium levels (MG 1, Table 12-12). Additionally, it has been proposed, low-voltage general-purpose Design B motors from 201 to 500 hp would meet MG 1, Table 12-11, minimum-efficiency levels.

The added motor types are:

-

U-frame.

-

Design C.

-

Close-coupled pump.

-

Footless.

-

Vertical solid-shaft normal thrust (tested in a horizontal configuration).

-

Eight pole (900 rpm).

-

Polyphase with voltages of up to 600 v, other than 230/460 v.

Motors with two-digit (56) frame designations are unaffected by EPAct and EISA regulations. IEC 90 and larger-frame motors must comply with EPAct and EISA efficiency.

The proposed timing of implementation is 36 months from the enactment of revised energy legislation. Thirty-six months would allow motor manufacturers time to adjust designs and factory equipment and adapt to changes in the supply of raw materials.

The EISA contains legislation specific to HVAC and commercial buildings intended to raise performance and reduce emissions (http://en.wikipedia.org/wiki/Energy_Independence_and_Security_Act_of_2007).

HOW MOTOR EFFICIENCY IS MEASURED

The U.S. standard test for motor efficiency is IEEE Standard 112, Test Procedure for Polyphase Induction Motors and Generators, Method B. The equivalent CSA test is CAN/CSA-C390-98, Energy Efficiency Test Methods for Three-Phase Induction Motors. The old IEC test standard, 60034-2, Rotating Electrical Machines, is not equivalent to IEEE Standard 112 because IEC 60034-2 assigns values to, as opposed to measuring, stray-load losses.

While the IEC procedure assigns stray-load losses, the old Japanese Electrotechnical Committee (JEC) 37 standard ignored them. Only the IEEE Standard 112, CAN/CSA-C390-98, and new IEC 60034-2-1 test methods compare measured input and output watts, giving a true measure of a motor's efficiency. Test results using IEC and JEC methods cannot be compared directly with IEEE Standard 112 or CAN/CSA-C390-98 results because they do not contain a measure of all of a motor's losses.

Measuring watts in and watts out allows for the segregation of a motor's losses into five categories:

-

Iron core: magnetic losses in laminations, inductance, and eddy-current losses.

-

Stator resistance: current losses in windings.

-

Rotor resistance: current losses in rotor bars and end rings.

-

Windage and friction: mechanical drag in bearings and cooling fans.

-

Stray load: magnetic-transfer loss in the air gap between the stator and rotor.

Table 3 shows segregated losses based on CAN/CSA-C390-98 tests of various motor designs. While motor designers debate how these losses should be distributed for performance characteristics, the total of the losses is most important to efficiency. For example, certain losses might be reduced further, but result in a motor incapable of starting across the line. Such a motor might be well-suited for use with an adjustable-speed drive or soft start that limits in-rush currents, but have difficulty starting across the line with a control bypass. Compromises often are made with general-purpose motors as a result of the designer's effort to balance performance parameters.

IMPORTANCE OF ELECTRICAL-GRADE LAMINATION STEEL

Over the last 20 years, development and refinement of motor designs has reduced internal losses, producing efficiency levels consistent with NEMA Premium. The primary advancement is better electrical-grade steel. Lamination coatings have evolved from basic organic (C3) to various inorganic/combination configurations (C4/C5/C6) to oxide coatings. Actual losses have gone from 4 to 5 w per pound of steel to less than 2 w per pound of steel.

On many AC motors above 449T Frame, C5 inorganic core plate is specified for low electrical losses and good resistance to degradation during burnout and rewind processes. The Electrical Apparatus Service Association (EASA) guideline for burnout temperature during rewind is 752°F. Some new proprietary oxide coatings allow temperatures as high as 896°F without damage.

Damage to lamination steel during an improperly performed rewind increases core losses. Table 4 illustrates the effect of increased core loss on a 50-hp (37-kw), two-pole ODP motor. It does not take long for the costs of operating a poorly rewound motor to exceed those of the rewind. Thus, select a service shop that follows ANSI/EASA AR100-1998, Recommended Practice for the Repair of Rotating Electrical Apparatus.

ADJUSTABLE-SPEED DRIVES

With newly designed HVAC units, motor speed is adjusted to control system airflow. The benefit of using an adjustable-speed drive is that by slowing down a motor and the driven load, energy consumption is reduced because of lower horsepower requirements. The use of vanes or dampers to control airflow has little effect on a fan's load as measured at the motor.

As fan speed increases, so do motor-power requirements (current). The motor is working harder, and more airflow is produced. As a damper closes, less air is supplied, but the motor is working at about the same amount of power.

With an adjustable-speed drive (inverter), on the other hand, as motor and fan speed and, thus, fan load decrease, motor load and power drop significantly. Many local utilities provide significant rebates for these upgrades.

If motor speed is not reduced, the addition of an adjustable-speed drive will not reduce energy consumption. The more a motor is throttled back, the greater the savings. NEMA Premium motors are friendly to the voltage and current waveforms produced by pulse-width-modulated adjustable-speed drives because most comply with the voltage requirements of NEMA MG 1, Part 31.4.4.2.

NEW TECHNOLOGIES

Much development using die-cast-copper rotors instead of aluminum rotors in AC induction motors has been done. While copper rotors have yielded improvements in efficiency, permanent-magnet (PM) rotors hold even greater potential. Additionally, they greatly increase power density. With a 180 Frame design, a conventional AC induction motor provides 5 hp, while a PM rotor can provide 30 hp. While only 20 hp is possible with a conventional 250 Frame AC induction motor, 100 hp is available with a PM rotor. Table 5 compares the efficiencies available with various motor technologies.

With continued development of PM-rotor motors, efficiencies of 98 percent or higher are possible with 400- to 500-hp designs. The efficiency of 250- to 500-hp four-pole TEFC AC induction motors would be 96.2 percent, with standard versions in the 95.8-percent range. Although that may not seem like much of a difference, with a 400-hp motor operating for three shifts with electricity costing 10 cents per kilowatt-hour, annual savings would be $1,134 and 11,340 kwh. New PM designs are well above NEMA Premium levels. Some large motors have tested to 98.3-percent efficiency. A 400-hp motor at 98.3-percent efficiency would save $5,805 a year over a 96.2-percent-efficient premium motor and $6,939 over a standard-efficiency motor.

CONCLUSION

Specify NEMA Premium motors for improved energy savings, reliability, and compatibility with adjustable-speed drives. Add adjustable-speed drives to variable torque loads for significant savings. Evaluate the cost of energy-efficient motors based on life-cycle cost, rather than first cost. Further reduce equipment-upgrade costs by taking advantage of rebates from utility companies and federal tax incentives.

Easy steps to energy efficiency also include:

-

Evaluate motors based on life-cycle cost, rather than initial price.

-

For continuous-duty applications, specify NEMA Premium efficient motors.

-

Consider upgrading to PM-rotor motors for even greater efficiency.

-

System-efficiency upgrades, such as the installation of adjustable-speed drives, are possible to maximize potential gains.

-

Consider grooved high-efficiency V-belts.

-

Use fan-system analysis tools from the DOE.

-

If possible, specify three-phase motors.

REFERENCE

- Information bulletin

(2008, December). Available at www.fmmi.at/uploads/media/Europump-Dezember08.doc

The AC- and DC-motor product manager for Baldor Electric Co., John Malinowski is a senior member of the Institute of Electrical and Electronics Engineers (IEEE), a member of the IEEE Industry Applications Society, and Baldor's representative to the National Electrical Manufacturers Association (NEMA) Premium, Motor Decisions Matter, Energy Star, and Standards for Energy Efficiency of Electric Motor Systems (SEEEM) programs. He has authored several articles on motor efficiency, maintenance, and application. George Weihrauch is a medium-AC-motor product manager for Baldor. His work includes application of specialized motors to meet specific needs for energy efficiency, longevity, and performance.