Meet the new Fan Energy Index

By THE AIR MOVEMENT AND CONTROL ASSOCIATION INTERNATIONAL FAN REGULATION COMMITTEE

Actions on the part of the U.S. Department of Energy (DOE) to regulate the performance of commercial and industrial fans and blowers have prompted Air Movement and Control Association (AMCA) International and its member companies to develop a new efficiency metric: fan energy index (FEI).

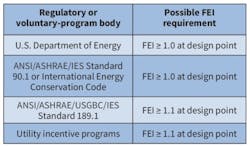

In the final stages of approval, FEI will replace existing fan-efficiency metrics in U.S. model energy codes and standards and already is being considered for utility incentive programs.

About FEI

Fans differ from other appliances in that their operating efficiency varies significantly based on how they are applied and where within their operating envelope they are selected. Unlike, for example, an incandescent lightbulb, a fan that is the least efficient for one application may be the most efficient for another.

Instead of specifying a minimum peak efficiency for each fan type, FEI establishes a baseline efficiency and a resulting baseline power that varies with airflow and pressure that are applicable to all fan categories. This establishes a range of compliant operations, rather than a single-point pass/fail efficiency threshold. Instead of eliminating inefficient models, FEI seeks to eliminate inefficient selections. What’s more, operating-point characteristics are built into the FEI calculation, so compliance officials need only to check the FEI rating on a label.

In the absence of a DOE test procedure, FEI is being formalized in an AMCA rating standard (BSR/AMCA Standard 208, Calculation of the Fan Energy Index) and the ISO (International Organization for Standardization) standard for fan efficiency (ISO 12759, Fans - Efficiency Classification for Fans). The harmonized AMCA and ISO standards will describe how FEI is calculated using data resulting from the organizations’ performance-rating tests.

Future Regulations

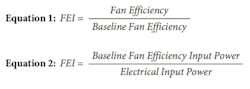

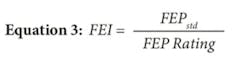

According to the Appliance Standards and Rulemaking Federal Advisory Committee (ASRAC), FEI is the ratio of actual fan efficiency to baseline fan efficiency (Equation 1) at a given airflow and pressure. Because each of these efficiencies is calculated at the same airflow and pressure, FEI also is defined as the ratio of baseline electrical power to actual electrical power (Equation 2).

Although equations 1 and 2 are equivalent, Equation 2 is preferred, as its specific mention of reducing electrical power consumption is more relevant to regulatory goals than increasing energy efficiency. Additionally, Equation 2 is easier to apply and works along an entire fan curve.

Equation 2 suggests there is an intermediary calculation leading to FEI, and there is: fan electrical power (FEP). FEP is obtained by either directly measuring fan electrical input power during rating tests or measuring fan shaft power and incorporating default values for motors and drives. The default values are defined in ANSI/AMCA Standard 207, Fan System Efficiency and Fan System Input Power Calculation. Fan rating tests can be conducted using ANSI/AMCA Standard 210, Laboratory Methods of Testing Fans for Certified Aerodynamic Performance Rating, which the ASRAC fan working group adopted as the basis of the DOE test standard.

FEP is compared against a baseline FEP (FEP_std), as shown in Equation 3. Note: FEP has engineering units of kilowatts, which cancel out when FEI is calculated.

Because FEI is inversely proportional to electrical input power, it provides an easy indication of energy savings. For example, a fan with a FEI of 1.05 uses 5 percent less energy than a fan with a FEI of 1.0, while a fan with a FEI of 2.0 uses half the energy of a fan with a FEI of 1.0. This makes FEI useful for calculating relative energy savings between any two fans or between a fan and the FEI threshold in a code, standard, or regulation.

Applying FEI

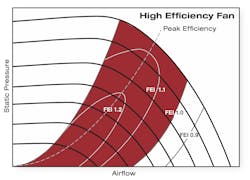

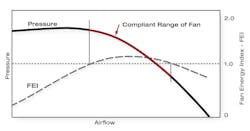

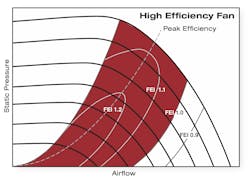

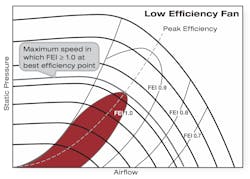

FEI defines a “compliant range of operation.” For a single-speed fan, the compliant range is a subsection of the total fan curve (Figure 1). For a multiple-speed fan, the compliant range looks like a bubble, the size of which is proportional to fan efficiency. Generally, the more efficient the fan, the larger the compliance bubble (Figures 2 and 3). In some cases, however, fans can be very efficient over a small operating range. The shaded regions in the figures indicate compliance FEI 1.0. Bubbles inside and outside the compliance zone indicate higher FEI levels and FEI levels below zero, respectively. In Figure 3, a label indicates the maximum speed at which the fan can be operated to be compliant. This gives operators and engineers an opportunity to implement variable-speed drives and belts to restrict fan speed.

Manufacturers will include such diagrams or their tabular equivalents in product literature and sizing/selection software to aid purchasing decisions.

The Benefits of FEI as a Metric

The ratio of fan power to baseline power at design conditions makes FEI easy to use. The baseline represents a reasonable efficiency level for all types of fans as normally applied. Though regulations can be written around FEPstd,1 a FEI of 1.0 could serve as an optimal requirement. When FEI is less than 1.0, allowable exceptions could include fans used for variable-air-volume systems to encourage more use of the systems. Fans used infrequently, such as emergency fans and fans used for material handling, also could have FEI requirements of less than 1.0.

Over time, as fan technology improves, the FEI metric will be able to withstand increased stringency in codes and regulations. For example, the baseline FEI could be moved from 1.0 to 1.1, which would nudge requirements higher while preserving the integrity of fans labeled with previously set FEI ratings. A fan’s label showing compliance with a requirement of FEI 1.0 would be valid if the requirement were raised to FEI 1.2. A building owner would replace a FEI 1.0 fan with a FEI 1.2 fan.

For those looking to be rewarded for efficiency, the Extended Motor Product Label Initiative (EMPLI) is developing a rebate program for motor-driven loads.2 Under EMPLI, AMCA, the Hydraulic Institute, and the Compressed Air & Gas Institute—representing fans, pumps, and air compressors, respectively—provide knowledge and experience in their given markets. When the AMCA FEI rating standard is complete, it should further enable rebate-program development and implementation.

Conclusion

By concentrating on the energy consumed by a fan as it is applied, FEI allows many different types of fans to be compared on equal footing. Further, it helps consumers see how a fan can be affordable and efficient at the same time and can assure manufacturers they are creating energy-saving products that will appeal to their customers. It is an all-encompassing, high-level solution to a complex problem.

References

EERE. (2015, September 24). Appliance Standards and Rulemaking Federal Advisory Committee Commercial and Industrial Fans and Blowers Working Group term sheet. Available at http://tinyurl.com/TermSheet2015.

Persful, T., Ivanovich, M., Wickes, G., & Rogers, E. (2016). A look at the extended product motor labelling initiatives for fans. Proceedings of the 2016 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA. Available at https://aceee.org/files/proceedings/2016/data/papers/6_587.pdf.

Mathson, T. (2016, April 6). Update on the impending U.S. fan efficiency regulation. Presented at the International Symposium on Fan Efficiency Regulation, Beijing.

This article first appeared in the December 2017 print edition of HPAC Engineering magazine.