University Touts New Hybrid Air Cleaning Alternative

While effective indoor air filtration technologies have long been a necessity in healthcare, schools, transportation and other settings, COVID-19 brought the need for clean and safe air to the forefront.

However, the pandemic also revealed the limitations of traditional options, such as HEPA filters and ultraviolet light disinfection devices, to effectively remove pathogens from the air. Those limitations led researchers at North Carolina State University to develop a filtration technology that presents a viable alternative for air cleaning in the 21st century.

N.C. State’s novel development combines the best performance characteristics of High Efficiency Particulate Air (HEPA) filters and ultraviolet light (UVC) devices into a single technology. The result is a 2D, lightweight, non-thermal, plasma-enhanced textile called FIL-TEX that is proficient at both capturing and killing bacteria, viruses and other contaminants with 99.9% efficiency.

Limits of traditional solutions

While high-MERV-rated HEPA filters have long been the gold standard for air filtration, they are still an imperfect solution for today’s needs. Although HEPA filters offer a 99.9% efficiency rating when it comes to collecting small particles and pathogens, they do not deactivate live bacteria and viruses. That makes replacing these filters potentially hazardous.

“Because HEPA filters merely capture particulates and pathogens and focus them in one place, there is a strong likelihood that any collected bacteria or viruses will be re-aerosolized when replacing the filter,” explains Dr. Warren Jasper, a professor in the Textile Engineering Chemistry and Science Dept. at the Wilson College of Textiles at N.C. State.

In addition, HEPA filters are frequently located in the air handling system, which is often located far from the rooms or settings from which collection is necessary. In other words, they are a whole-building solution versus an intermediate one.

“Essentially, they are often placed too far away to provide protection to areas where people are congregating,” says Jasper. “If someone coughs in a crowded classroom, the fact that there is clean air near the air handler doesn’t really protect the individuals from the airborne particulates that have just been released into the room.”

Similarly, UVC disinfection technologies are growing in popularity because they successfully deactivate live pathogens and microorganisms by destroying their DNA. But these systems utilize UV light mechanisms, which can cause adverse health effects, such as headaches and skin cancer, in individuals who are over-exposed to UV rays. That makes UVC a poor choice for crowded, highly populated settings.

In addition, when UVC technologies are combined with HVAC systems, as is often the case, operational and maintenance expenses may increase due to higher power requirements and costly bulb replacements.

Mixing passive, active technologies

Understanding the drawbacks of these traditional technologies, which date back to the 1930s and 1940s, researchers at N.C. State have developed an effective and contemporary method of providing clean and safe air that they believe is suitable for today’s post-pandemic needs.

“Filtration of airborne particulates can be divided into two camps – active and passive,” explains Dr. Jasper. “We decided to take the best performance characteristics from passive technologies that capture particulates and active technologies that purify the air and combine them into a single, more modern air cleaning solution.”

He adds that FIL-TEX is comprised of woven, knit or non-woven structures where non-conductive yarns are combined with conductive yarns that serve as electrodes. When a voltage is applied to these conducting yarns, a non-thermal plasma (NTP) is produced.

NTP, often called cold plasma, is an electrically energized form of matter that remains cool to the touch but is composed of a partially ionized gas that reacts with pathogens, chemicals, odorants and other contaminants and converts them into harmless oxidized forms.

So, when airborne pathogens pass through the FIL-TEX filter, the NTP reacts with the sheath membrane of the microorganisms, deactivating the virus or destroying the cell wall of the bacterium, essentially killing any airborne pathogens while also safely collecting them.

In addition, because it operates like a magnet that attracts, deactivates and removes unwanted contaminants from the air, FIL-TEX technology does not emit any additives or substances into the air.

Close quarters demand proper ventilation

Following the COVID-19 pandemic, technology that effectively eliminates aerosolized pathogens is extremely important in confined spaces where people congregate.

“While good air circulation helps reduce the likelihood of the transmission of airborne viruses and bacteria, effective filtration is crucial in locations where there is not much air turnover and in which we pack a lot of people,” says Dr. Frank Scholle, Associate Professor of Biological Sciences at N.C. State. “Close quarters without proper ventilation, such as gateways between the airport and airplane; buses or subways; classrooms; and exam or waiting rooms in healthcare settings, provide an ideal environment for very contagious respiratory pathogens, such as COVID-19, chicken pox and measles, to transmit between people.”

Based on these needs, N.C. State researchers in Dr. Scholle’s virology lab tested the effectiveness of FIL-TEX, which was originally developed to remove smoke and particulates, against respiratory pathogens. They were more than satisfied with the results.

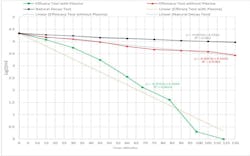

An aerosolized coronavirus, similar in genetic makeup to the virus responsible for COVID-19 infections, was introduced into an enclosed laboratory-scale tunnel with FIL-TEX situated between the inlet and outlet. A sampling of the air before and after passing through FIL-TEX demonstrated encouraging post-filtration effectiveness of the novel technology.

“We had nearly a 3-log reduction in infectious virus after the FIL-TEX filter, to be specific up to a 99.7% effectiveness,” says Scholle. “The destruction of infectious virus was a truly significant level of success and was beyond our initial expectations.”

Following N.C. State tests, FIL-TEX was sent to CREM Co Labs – an independent R&D laboratory in Ontario specializing in antimicrobial testing – which conducted similar analyses and found equally impressive results. According to that report, FIL-TEX removed over 99.9% of airborne viruses, such as COVID-19, and 99.9% of airborne bacteria, such as staph, while deactivating 98% of viruses found on the filter’s surface.

FIL-TEX has also been shown to rapidly absorb continuous smoke and particulates such as oil, carbon, soot, ash and tar in enclosed spaces where venting is not an option, making it an effective air cleaning technology with many potential applications, according to the research findings.

Hitting the market

Specifically, FIL-TEX combines NTP technology with a 2D textile filter that can be made from cotton, polyester, polypropylene, Kevlar or other fabrics, so it is lightweight and flat with a thickness of only about 2 mm. The textile filter is designed in such a way that air can pass through the system at a high rate and requires very little power making it an effective and energy-efficient component suitable for a number of air cleaning devices and systems. These applications may include a wall- or ceiling-mounted device, or in conjunction with other HVAC systems.

FIL-TEX is now available through North Carolina-based Stitch Partners, which has licensed the intellectual property from N.C. State. It is available to air cleaner manufacturers that can incorporate the filter as a component in the development of new or current systems.

##########

The author is a Houston-based freelance writer with more than 20 years of experience writing about the HVAC industry, mechanical engineering, and clean technology.

For more information on FIL-TEX, go to StitchPartners.com.

About the Author

Greg Rankin

Freelance Writer

The author is a Houston-based freelance writer with more than 20 years of experience writing about the HVAC industry, mechanical engineering, and clean technology.