From schools, factories, and offices to shopping centers and residential buildings, thermal comfort is an important topic for both occupants and engineers in charge of building these constructions. Add to this the need to comply with energy efficiency standards and you get a real challenge for HVAC designers and mechanical engineers.

For commercial and residential buildings, ASHRAE 55 and EN 15251 distinguish themselves as the primary thermal comfort standards, providing a minimum set of requirements for a building design to ensure comfortable thermal conditions. ASHRAE 55, for instance, includes a series of personal and environmental factors—metabolic rate, clothing insulation, air temperature, radiant temperature, air velocity, and relative humidity. While the first two cannot be influenced by engineers, the rest can—by identifying the optimal air conditioning, ventilation, and heating system as well as its best possible placement.

In determining the best HVAC design configuration and complying with such a thermal comfort standard, computational fluid dynamics (CFD) makes the difference in most cases.

HVAC Design Testing and Optimization: Case Study Ramboll

With CFD simulation, designers can virtually test an indoor space and compare different HVAC system configurations, identifying design flaws and improvement potential.

Until recently, due to the high costs and several accessibility barriers of traditional providers, CFD software was expensive to use and lacked flexibility. With the emergence of cloud-based simulation tools, however, this powerful technology has become an affordable and user-friendly solution for virtual prototyping. SimScale, the market leader in online simulation, offers yearly subscriptions and extensive support for their simulation platform, as well as a possibility to try it out for free through a Community account. Create a free account to test online simulation here.

In this CFD case study from SimScale, a project of the renowned engineering and design company Ramboll is described. Its focus was the design of a school building in Scotland after the Department of Education issued more restrictive thermal comfort standards.

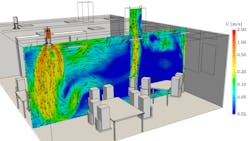

The goal of this project was to simulate the performance of an air-mixing plenum (mixing box) considering a winter scenario. The results of the airflow simulation ran online with SimScale were related to velocity, temperature distribution, and thermal comfort.

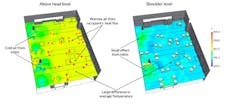

Looking at the velocity distribution, the engineers could identify three regions of the airflow—the inlet flow velocity, the flow velocity through the grills, and the buoyancy draft velocity. These results showed that the students would not be strongly affected by the draft with the existing design.

When they investigated temperature, however, several highly uncomfortable areas below the inlets were identified, which indicated that a rearrangement of the tables and chairs was required, to avoid placing any student in those areas.

To estimate thermal comfort in this project, effective draft temperature (EDT) was used. As CFD simulation enabled the estimation and visualization of EDT for every point in the classroom, it was essential in reaching a final, optimized design.

For a more detailed analysis of the simulation results, as well as a commentary on the project by Ian van Duivenbode, Senior Building Physics Engineer at Ramboll UK, you can watch the webinar recording below:

Sponsored by: