The Case for High-Performance Variable-Air-Volume (VAV) Systems

In recent years, engineers have been encouraged to turn away from variable-air-volume (VAV) systems by manufacturers of decentralized HVAC technologies and by parties who view VAV systems as antiquated, inefficient, or too difficult to design or operate. The State of Washington even went so far as to make decentralized HVAC its new benchmark system for energy codes for five types of commercial buildings, while providing exceptions for what it codified “high-performance VAV” systems (see “Specifications for High-Efficiency VAV Systems,” September 2016).

One System for Heating, Cooling, and Ventilation

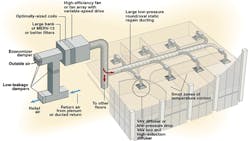

A HPAS is a VAV system that optimizes energy efficiency, comfort, and indoor-air quality (IAQ), incorporating heating/cooling and ventilation in a single ducted delivery system. With inherent potential to be energy-efficient, VAV systems form the basis of model energy codes and standards, such as ANSI/ASHRAE/IES 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings, and the International Energy Conservation Code. High-performance VAV systems take things a step further by integrating the best practices of rightsizing, zone optimization, outside-air-based free cooling, and coil cleaning using ultraviolet (UV) germicidal lamps. Also, these systems minimize static-pressure drop, system leakage, and system effects. Beyond energy efficiency, these centralized systems provide healthy indoor air and require less maintenance than decentralized HVAC technologies with a wide distribution of smaller fans, coils, controls, and filters.

HPAS Benefits

Benefits of a HPAS include:

- High energy efficiency. The most prominent benefit of a HPAS is energy efficiency.

- Low life-cycle cost. Because of its energy efficiency, a HPAS has a low life-cycle cost. Cooling energy-cost savings are significant, as free cooling is available in a considerable number of climate zones. Fan energy savings also are significant because of a lower air-system static pressure and optimal fan sizing and selection when comparing HPAS to minimally compliant VAV. Additional energy savings can be found from on/off control via scheduling, the use of high-efficiency motors and variable-frequency drives, and demand-controlled ventilation.

- Low first cost. Integrated centralized systems typically have lower first costs than other systems, though this depends on variables such as location (climate) and construction practices.

- Minimal-risk refrigerant system. The possibility of refrigerant leaking into occupied spaces is a safety concern with some technologies. With a HPAS, refrigerant is centralized in an equipment room or rooftop unit instead of above the ceiling of, or in a closet adjacent to, an occupied space. This has the additional benefit of reducing the need for sensors and sensor maintenance related to refrigerant monitoring.

- Improved comfort, flexibility, and efficiency. A HPAS has small temperature-control zones, which can be the size of an office. A refrigerant-based-system temperature-control zone must be large enough to disperse a full system refrigerant charge safely in the event of a leak in a particular zone.

Installed-System Benefits

Typical installed-system benefits include:

- Improved IAQ. A HPAS uses MERV-13 (or better) filters and UV surface cleaning, which reduces maintenance (fewer filters and continuously cleaned coils, drain pans, and cabinets).

- Reduced noise pollution. Fans in a HPAS are in a central location, well away from occupied spaces.

- Adaptability. Small zones easily adapt to moved walls and other office-layout changes. When needed, moving diffusers and duct-takeoff branches is easier than moving fan-coil units and refrigerant lines.

- Safe and easy maintenance. Often, a HPAS requires no scheduled maintenance in occupied spaces. The parts of a HPAS needing the most service are in a central location, away from occupants and easily accessible at any time.

- Third-party-certified component performance. Most air-side HPAS components (fans, dampers, louvers) are certified by AMCA, assuring products will perform as rated if they are designed and installed properly. AMCA certifies ratings test data for air performance, sound levels, weather resistance, air leakage, and more. AMCA has published a series of white papers summarizing its Certified Ratings Program and providing guidelines for requiring AMCA-certified products.

How HPAS Boost Efficiency

Several energy-reducing features distinguish HPAS:

- Optimized fans, reduced pressure drop. To lower fan energy consumption, system designers achieve the best airflow performance by selecting the fan with the lowest power (which is not always the lowest-cost or smallest fan). Further optimization results from lowering design supply-air temperature, specifying low-leak spiral/oval ducting, and not oversizing design loads. Other high-performance features include design of lower-pressure-drop air systems using optimized coils, large filter banks, round or oval ductwork designed to use static regain, low-pressure-drop terminals, and plenum returns. More optimization is delivered when selecting efficient electronically commutated or direct-drive motors and variable-speed drives for part-load energy savings. Cooling and heating for a HPAS is provided by either a high-efficiency chiller/boiler combination or a high-efficiency packaged VAV rooftop unit equipped with high-efficiency gas-fired furnace.

- Free cooling. Today’s tight building envelopes with high occupant densities and internal loads require year-round cooling in interior zones. HPAS bring in free, cool air when outside temperatures or enthalpy are right.

- Sophisticated control. HPAS advanced control technologies increase energy savings through building-automation strategies such as demand-controlled ventilation, supply-air-temperature reset, and static-pressure reset.

Conclusion

A HPAS performs significantly better than minimally code-compliant VAV systems and decentralized systems, which makes them well-deserving of their high-efficiency name. They optimize energy efficiency, comfort, and IAQ while focusing on rightsizing, zone optimization, and outside-air-based free cooling.

When considering design approaches for ventilation, be sure to consider a HPAS over traditional VAV, and look carefully at comparisons of the performance of decentralized HVAC to that of HPAS.

Reference

AMCA. (2017, January). Introducing high performance air systems. Available at http://bit.ly/Introduction_HPAS