Optimizing Dedicated Outdoor-Air Systems

Though vital to maintaining good indoor-air quality, outdoor air can be expensive to temper and, if not conditioned properly, cause humidity problems in a building. Increasingly, designers are finding dedicated outdoor-air systems (DOAS) to be an energy-efficient and easily verifiable way to comply with ANSI/ASHRAE Standard 62.1, Ventilation for Acceptable Indoor Air Quality.

This article will discuss DOAS, which supply cooled, dehumidified outside air to buildings such as schools, dormitories, hotels, and assisted-living facilities during summer and heated outside air during winter.

HOW IT WORKS

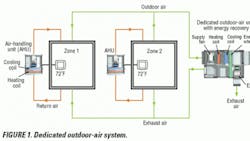

A dedicated outdoor-air unit is sized to deliver the amount of conditioned outdoor air required to handle the latent load of a space. This requires a supply-air dew-point temperature (DPT) lower than the room-air DPT (typically, 45°F to 52°F).1 Space sensible load is decoupled from latent load, allowing precise humidity control, regardless of space thermal load. This minimizes the humidity-control problems often associated with part-load operating conditions. Local HVAC units (parallel variable-air-volume systems, water-source heat pumps, fan-coil units, air-handling units, induction units, etc.) are responsible only for the sensible heating or cooling needed for a space (Figure 1).

OPTIMIZING A DOAS SYSTEM

Maximizing savings from a DOAS requires evaluation of the use of energy recovery, supply-air temperature, supply-air-delivery location, and control strategies.

Energy recovery

Because DOAS are 100-percent-outdoor-air systems, energy recovery is required in most cases per ANSI/ASHRAE/IESNA Standard 90.1-2007, Energy Standard for Buildings Except Low-Rise Residential Buildings, which states: “Individual fan systems that have both a design supply-air capacity of 5,000 cfm or greater and have a minimum outside-air supply of 70 percent or greater of the design supply-air quantity shall have an energy-recovery system with at least 50-percent recovery effectiveness. Fifty-percent energy-recovery effectiveness shall mean a change in the enthalpy of the outdoor-air supply equal to 50 percent of the difference between the outdoor air and return air at design conditions.” Many municipalities are beginning to legislate Standard 90.1 language into their building codes.

In non-arid climates, total-energy- (or enthalpy-) recovery wheels can help reduce the first cost of equipment by reducing the mechanical-cooling load of a DOAS by 3 to 4 tons per 1,000 cfm of outside air.2 Additionally, energy wheels reduce outdoor-air heating and cooling loads, which leads to annual energy savings. Utilizing energy recovery also can eliminate the need for exhaust fans, which helps to justify the cost of routing building exhaust back to a dedicated outdoor-air unit.3

Total-energy wheels ease the burden of dealing with part-load conditions. Because a wheel transfers both sensible and latent energy, it “compresses” the ambient air entering a downstream cooling coil, restricting ambient-air conditions to a small radius around the room conditions (Figure 2). This is particularly important for direct-expansion equipment, in which excessive compressor cycling at low-load conditions leads to a loss of humidity control.

Depending on the climate and end-user preference, plate-type heat exchangers can be implemented with a DOAS. Plate exchangers typically provide energy recovery through sensible preconditioning of outdoor air. For relatively low-volume applications, total-energy-recovery plate exchangers are available.

Supply-air temperature

As mentioned previously, for an entire latent load to be handled, supply air must be dehumidified to a dew point lower than that of the space. Designers must decide whether to supply air off of a cooling coil at “space-neutral” or “cold-air” conditions. With the former, dehumidified air is reheated to room conditions to introduce fresh air into a space without affecting thermal loads, and all of the sensible cooling done during dehumidification is wasted. With the latter, the air coming from a unit is left at the temperature coming off of the cooling coil, and the outdoor air is able to handle some of the sensible cooling in the space. By decreasing the sensible loads in the space, the cooling capacity and annual energy consumption of the local HVAC unit are reduced significantly. In the case of a typical wing of classrooms in a school, supplying cold, rather than space-neutral, air reduces local-HVAC-unit size by up to 40 percent.4

Supply-air-delivery location

Designers must decide whether to deliver outdoor air directly into individual spaces or into the local HVAC unit.

Delivering air directly into a space is the more economical option and the easier way to verify the required volume of outdoor air is being supplied. Also, it has a greater effect on thermal loads. Because a local HVAC unit needs to be energized only on a call for cooling or heat from a space, it does not need to be running when there is no call for tempering. This can greatly reduce the fan-energy consumption of the unit. Additionally, the unit will need to be sized only for the air volume required to satisfy the space sensible load, rather than the entire supply-air volume, saving on first cost, reducing physical size, and potentially reducing sound levels.

When outdoor air is ducted directly to a local HVAC unit, the cooling capacity of the unit can be decreased, but the unit needs to be sized to handle the entire supply-air volume. In such cases, it is highly recommended that the dedicated outdoor-air unit not reheat the outdoor air to avoid the local unit having to cool air that already has been cooled once.

Control strategies

When a building is occupied, a dedicated outdoor-air unit is energized and supplying conditioned outdoor air to a space. Local HVAC units are energized upon a call for cooling or heat from the space. This allows the precise volume of outdoor air to be delivered independent of space cooling or heating status. Several measures can be implemented to further enhance system performance:

-

Resetting discharge temperature based on outdoor air

When outdoor-air conditions are such that overcooling is likely, supply air is reheated to a neutral temperature. This can be accomplished using a microprocessor controller that monitors ambient temperature and resets the discharge temperature of the outdoor-air unit accordingly. A more advanced approach is to implement a building-management system (BMS) that can monitor multiple spaces and determine the “critical space.” Once the critical space is determined, the BMS can adjust the reheat capacity of the outdoor-air unit to prevent overcooling or overheating of the critical space.

-

Implementing a dehumidistat

If a room becomes too humid, the dehumidistat sends a signal to the microprocessor controller that more dehumidification is needed. The controller then lowers the discharge dew point of the outdoor-air unit. Once the room humidity reaches an acceptable level, the dew point is reset to normal operation.

CODES AND STANDARDS

Building codes and standards continue to drive requirements for increased outdoor-air ventilation rates. Engineers and building owners will want to pay special attention to:

Standard 62.1, which sets minimum ventilation rates and other requirements for commercial and institutional buildings. Leadership in Energy and Environmental Design for New Construction and Major Renovations Green Building Rating System requirements can exceed Standard 62.1 ventilation rates by up to 30 percent.

Standard 90.1, which mandates air-side energy recovery when supply-air capacity is 5,000 cfm or more, minimum outdoor air is 70 percent or more, and system effectiveness is 50 percent or more.

A proposal to improve upon American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) requirements by addressing specific climate variations within the United States is being considered. The proposal, referred to as Addendum e to Standard 90.1-2007, has gone through the public-review process and is on the agenda for publication approval during ASHRAE's 2010 Winter Conference in January. The proposed enhancements are shown in Figure 3.

Proposed ASHRAE Standard 189.1, Standard for the Design of High Performance, Green Buildings Except Low-Rise Residential Buildings, which mandates energy recovery, including outdoor-air rates as low as 10 percent of total supply air (Table 1). The 2006 International Energy Conservation Code, which includes language from Standard 90.1 as it relates to supply-air fan systems and energy-recovery requirements.SUMMARY

DOAS provide a straightforward, energy-efficient approach to handling ventilation air. The use of energy recovery, supply-air conditions, supply-air delivery location, and sequence of operation are important to maximizing annual energy savings and comfort.

Incorporating air-to-air total-energy-recovery devices into DOAS can reduce the energy needed to cool and heat ventilation air significantly. The technology is cost-effective, with payback periods ranging from less than one year to three years for most applications.

Codes and standards are mandating ever-more-energy-efficient HVAC systems and technologies. Engineers and owners must stay abreast of these developments to ensure not only compliance, but that the economic benefits of specifying optimal equipment are realized.

REFERENCES

-

Mumma, S.A. (2007, August). DOAS & desiccants. Engineered Systems.

-

Greenheck. (1999). Energy recovery ventilators: The engineer's solution (ERA/100-00). Retrieved from http://www.greenheck.com/library/articles/19

-

Murphy, J. (2006, July). Smart dedicated outdoor air systems. ASHRAE Journal, pp. 30-37.

-

Greenheck. (2007). Optimizing dedicated outdoor air systems (ERA/114-07). Retrieved from http://www.greenheck.com/library/articles/79

The general manager of tempered-air products, Mike Wolf, PE, has been with Greenheck for 23 years, during which his responsibilities have included engineering, manufacturing, marketing, and sales. He is a past chairman of Air Movement and Control Association International's HVAC Fire & Smoke Damper Engineering and Air Control Engineering committees. Jackson Smith is a senior application engineer within Greenheck's tempered-air-products group. His HVAC focus is on building ventilation, with an emphasis on energy recovery.