Association Solutions — HVAC Fan Efficiency Codes and Standards: The Pressure is On

Starting with the 2012 International Green Construction Code (IgCC), fan-efficiency requirements began appearing in model codes and standards for energy efficiency and green construction. There’s a first-ever requirement in ANSI/ASHRAE/IES 90.1-2013, Energy Standard for Buildings Except Low-Rise Residential Buildings.

Another will appear in the 2015 International Energy Conservation Code (IECC).

A proposed addendum to ANSI/ASHRAE/USGBC/IES 189.1, Standard for Construction of High Performance Buildings Except Low-Rise Residential Buildings was approved for public review in November 2013.

If the addendum to 189.1 goes through, all four U.S. model codes and standards for energy efficiency and green construction will have a fan efficiency provision. The IAPMO (International Association of Plumbing and Mechanical Officials) Green Plumbing and Mechanical Code Supplement also will have a fan efficiency provision in its next issue.

Meanwhile, the U.S. Department of Energy has initiated a “rule-making” process that will establish a federal standard for commercial and industrial fans and minimum efficiency requirements. The rule making is expected to be complete by 2016 and take effect in 2019.

So, what was, until recently, an under-served topic in the buildings industry has suddenly become important and complex. AMCA International has been at the forefront of these developments. In 2010, AMCA published AMCA Standard 205, Energy Efficiency Rating for Fans, and championed the changes to the model codes and standards. All fan-efficiency requirements in the codes and standards are written around AMCA 205; so, to understand what’s in the codes and standards, engineers need to understand AMCA 205.

SOLUTION: AMCA 205

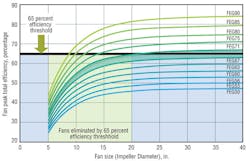

AMCA 205 has two key elements. First, it defines a new efficiency metric, called fan-efficiency grade (FEG), which enables regulators to write simple, enforceable fan provisions. In 2007, when fan-efficiency requirements were first being considered for ASHRAE 90.1, it soon became apparent that an efficiency threshold for fans would be difficult to set. Efficiency depends on fan diameter. Setting an efficiency requirement for 65 percent, for example, would eliminate most fans under 20-in. in diameter. The FEG metric, which is a unitless index calculated from data taken during fan-rating tests, accommodates this phenomenon (Figure 1). Each FEG band represents a range of efficiencies that approach the FEG level for the band in larger fans. For example, FEG 67 includes fan efficiencies of 64, 65, 66, and 67 percent at the plateau for fans greater than 20 in. in diameter, and efficiencies as low as 35 percent in the 5-in.-diameter size.

Second, AMCA 205 recognizes that regulating the FEG level of a fan alone is inadequate for reducing fan energy consumption—rightsizing fans is also important. AMCA 205 stipulates that fans should be sized/selected to operate within 15 percentage points of the fan’s rated peak total efficiency. Changing FEG level alone would NOT save energy if selections drift to smaller fans as a response to increased manufacturing costs of more efficient fans.

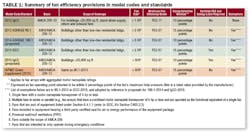

The model codes and standards have or are proposed to have two-part fan-efficiency provisions. Part one sets the minimum fan aerodynamic efficiency requirement using a fan efficiency grade. Part two sets the sizing/selection window of the fan operating point relative to the fan’s rated peak total efficiency.

Scope of coverage and exemptions are also part of these provisions. Table 1 summarizes the efficiency provisions in the four model codes and standards and the IAPMO Green Supplement. Because these are first-generation requirements for fans, the provisions are not as stringent as some would expect. This is deliberate.

Manufacturers and engineers need to become familiar with the FEG metric and accommodate wider use of fan total pressure in selection of fans used on ducted systems. Second-generation fan-efficiency requirements will build upon the lessons learned from the first-generation codes and standards.

Second-Generation Fan Requirements

As mentioned earlier, simplicity and facilitation of learning were important considerations in setting the fan efficiency requirements in model codes and standards. There is one FEG threshold and sizing/selection window for all types of fans and fan sizes. Exemptions are used to exclude fan sizes and types where this efficiency requirement or selection approach does not work.

The second-generation requirements are expected to be more complex and ultimately more stringent. One significant change in complexity will be the establishment of different categories or types of fans and, for each one, the setting of an independent, minimum FEG and selection range.

For example, centrifugal fans will have a higher FEG requirement than axial fans. Sizing/selection windows could also be tailored to fan types, for example, having tighter windows for fan types with flat efficiency curves and wider windows for fan types with steep efficiency curves. Sizing and selection windows will be set using fan total pressure for some fan types and static pressure for others (such as powered roof ventilators) that are not generally applied with outlet ducts that can convert velocity pressure to overcome static-pressure losses.

Also, there could be new metrics defined for fans sold with integrated motors and drives; these assemblies may choose to comply with a minimum wire-to-air efficiency metric.

These changes will eliminate all or most of the exemptions and increase the energy savings from current fan efficiency requirements.

Resources

Fan-efficiency requirements are new to the industry, and a lot has happened in the past few years. Engineers, manufacturers, distributors, contractors, code officials, commissioning providers, and building owners need to come up to speed rather quickly because ASHRAE 90.1 is now available for adoption, and IECC-2015 is in the wings.

To help with this, AMCA has been publishing technical articles in the trade press regularly since 2010 and made AMCA Standard 205 available for no cost. All relevant articles and the 205 standard are available on the AMCA Website: www.amca.org/feg. The technical articles are in Best Practices. Codes and standards developments, updates, and links pertaining to the DOE regulation and AMCA 205 are in the Codes and Standards section.

Also, because IECC-2015 and proposed IgCC-2015 provisions require third-party certified FEG ratings, AMCA has updated its online database of AMCA-certified products to facilitate searches for FEG ratings. That utility is available at www.amca.org/feg/feg-finder.aspx.

Online Resources

- Technical articles: www.amca.org/feg/best-practices.aspx

- Codes/standards/regulations: www.amca.org/feg/codes-and-standards.aspx

- AMCA FEG-Finder web page: www.amca.org/feg/feg-finder.aspx

Other References

- International Code Council, International Green Construction Code (IgCC), 2012.

- ASHRAE, ANSI/ASHRAE/IESNA 90.1-2013, Energy Standard for Buildings Except Low-Rise Residential Buildings.

- ANSI/AMCA 205-12 Energy Efficiency Classification for Fans, Air Movement and Control Association International, 2012.

- Cermak, J. and Ivanovich, M., April 2013. “New Fan Efficiency Requirements for ASHRAE Standard 90.1-2013,” ASHRAE Journal, ASHRAE.

- Brendel, M. May 2013. “The Role of Fan Efficiency in Achieving Energy Reduction Goals,” HPAC Engineering Magazine, Penton Media.

- Ivanovich, M., “Special report: Fan efficiency guidelines,” Consulting-Specifying Engineer, CFE Media.

Michael Ivanovichdevelops and advocates consensus positions among AMCA member companies on energy efficiency and green construction codes. AMCA International is a not-for-profit manufacturers association with +320 member companies in North and South America, Europe, Asia, and the Middle East.