War Story: Burner-System, Controls Upgrade Causes Reliability Issues

Has your organization retrofitted burners and controls on its boilers because of U.S. Environmental Protection Agency- (EPA-) mandated emission regulations and then experienced operational issues? The owner of a large manufacturing-and-assembly facility in the Midwest did, and while conducting an operational review there in mid-2014, I experienced firsthand the frustrations of the plant engineering staff.

The System

During the mid-1990s, the facility underwent a major production-capacity expansion that included new central air-conditioning equipment and the replacement of an aging steam plant with three new gas- and oil-fired D-frame boilers and auxiliaries. Because the facility was located in a national ambient-air “non-attainment” region, low-nitrogen-oxide (NOx) burner systems had to be installed on the boilers to achieve stack-emission levels of 50 ppm.

Subsequently, the EPA promulgated stricter regulations for the region largely because of increased automobile and air-traffic emissions. For large stationary boilers and process combustion burners, the maximum NOx-emissions level was lowered to 16 ppm.

The low-NOx burner systems could not achieve the new emissions limit; thus, an upgrade of the combustion system and controls was necessary. The retrofit was conducted by a design firm and a controls company different than the ones used for the original installation.

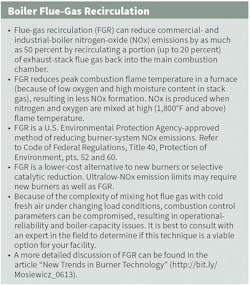

The retrofit included “cutting-edge” technology—ultralow-NOx burners, flue-gas recirculation (FGR), variable-speed drives (VSDs) on fans, steam-coil air preheaters in fresh-air-supply ducts, oxygen (O2) trim for stack gas—to meet emissions requirements.

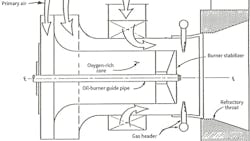

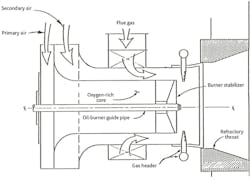

Figure 1 is a schematic of a low-NOx burner. This is a conceptual arrangement, as gas spuds and diffuser plates vary by manufacturer.

Steam demand was used primarily for two somewhat different plant systems:

- Process hot water and HVAC (generally, steady-state loads). One of the three boilers easily could handle the normal steam demand at half to three-quarters load, but a second unit was kept in service at a minimum firing rate because of frequent “trips” of the lead boiler. Weekly switching of the lead/lag units to improve boiler-operator competence had not made much of a difference.

- Direct steam injection (for a vacuum sterilization process). This required a large volume of steam for several hours a couple of times a week. Under normal operation, two of the boilers were set up to split the much higher steam load. Also, steam-header pressure was increased to mitigate line loss to the remote vacuum-process area. Because the steam was being vented, a large volume of cold makeup water was required for the deaerator. Deaerator performance later was deemed to be of concern.

The new combustion-control system and burner-management logic included a complex array of computer terminals and display screens with alarm panels, strip charts, and flashing status lights, a major upgrade from the original 1960s boiler plant. It was obvious the boiler operators were overwhelmed when a trip condition occurred.

System Evaluation

- The steam-header pressure set point was being raised by 25 percent prior to vacuum-system startup. That would change steam-flow characteristics. This was not part of the control-system logic. Low-water trips would occur if the boilers were not switched to manual drum-level control during ramp-up.

- Air supply was a major concern. Both the fresh-air duct and the FGR duct had independent damper drives to control flow, pressure, and temperature to the burner plenum chamber. Adding a VSD on the fan motor made for an extremely complex set of conditions to program into the control logic. Moreover, the steam preheat coils had tempering air dampers for summer/winter mode. Static air pressure in the supply-duct plenum could be an issue during load change.

- The combustion-control logic was set up to give priority to the in-situ stack-gas NOx and O2 sensors in the air permit. The boilers were tripping on “flame failure.”

As boiler load would increase, exit stack-gas temperature would increase, as would the FGR gas stream, causing density and static-pressure change in the combustion-air supply that would have to be corrected by the complex control system.

Appreciate that flue gas contains a large amount of carbon dioxide (CO2). At 18 percent to 20 percent CO2 in the supply of combustion air to the burner, flame stability could be an issue. Exacting measurement and control were crucial. It would take only an instant for an infrared flame scanner to sense a flickering-flame condition. Damper drives and the VSD would be competing for airflow control. A highly sophisticated VSD was necessary.

Recommendations

We monitored a few days of operations that included several boiler-trip incidents, held separate discussions with operators on all shifts, and conducted a thorough review of the equipment and controls.

It was apparent numerous system changes were needed. But first, a technical discussion to apprise the engineering staff and controls company of the complexity of the challenge before them was necessary.

It was not a strict combustion-system safety matter—the flame-safety system and water-level-control trip devices were working well—but, rather, a question of how to effectively manage a very sophisticated burner system in a more reliable manner. What’s more, the issues were not the result of marginal-quality equipment or controls. The plant’s design was robust, with utility-grade equipment utilized throughout. How the control systems and personnel responded to rapidly changing load conditions was the main challenge.

Subsequent review resulted in the following general recommendations:

- Changes to several operating procedures.

- Modifications of the combustion-control system and BMS program logic.

- A few crucial equipment modifications and control set-point changes.

- Thorough technical training for all boiler personnel and their direct supervisors.

Summary

When latest-technology control equipment is being integrated into older-generation boiler systems, it is essential to utilize consultants with extensive retrofit experience during not only design, but commissioning and training.

An engineering consultant with JoGar Energy Services, Gary W. Wamsley, PE, CEM, has more than 40 years of experience with industrial boiler and process burner systems. He is a member of HPAC Engineering’s Editorial Advisory Board.