Clean rooms, along with other critical environments, require the precise control of temperature, relative humidity, air quality and its distribution that is not considered common in more traditional indoor spaces.

One highly important but often neglected aspect of achieving a successful outcome centers around an in-depth understanding of how to effectively control electrostatic charges in these spaces, which when accomplished in combination with the other specific design and application techniques mentioned above, allow these rooms to attain the ultimate level of cleanliness usually required.

The use of electrical devices, synthetic materials or finishes, and low humidity levels can lead to the undesirable generation of high electrostatic charges within these indoor environments. While this occurrence is experienced in almost all spaces, its effect cannot be overlooked or underestimated in clean rooms as it can be extremely detrimental and even disastrous to its intended use and outcome.

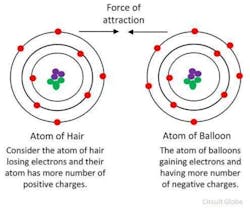

Static electricity is produced by the action of contact and separation of dissimilar materials. The technical explanation that has long been accepted describes the interaction of electrons between two surfaces as they come into contact. Upon separation, the electron will attempt to return to its source material, and the speed of separation of the two surfaces results in the electron remaining predominantly with the more resistive material. The more resistive material then has a surplus of electrons and is called negatively charged. The other material, being less resistive, now has a deficiency of electrons or is positively charged.

A clean room, because of the many non-conductive surfaces, is inherently an area susceptible to high static generation which can significantly disrupt processes. When static charge that is stored on one surface transfers to another, it results in an electrostatic discharge event (ESD). Because most ESD events are indiscernible to the naked eye, cleanroom workers are not aware that it is occurring. Happening quickly and invisibly, this can permanently damage sensitive electronics and prevent samples from being weighed accurately.

ESD can also vaporize metal lines on semiconductors, melt silicon and cause device failures; damage masks, reticles, wafers, and disk drive heads, cause random defects on flat panel displays, along with producing equipment failures. Additionally, ESD events can generate Electromagnetic Interference (EMI) and while most equipment is designed to tolerate a certain amount of EMI, if it exceeds specific limits it can result in malfunctions and errors.

Figure 1. Static Electricity

Surface-borne contaminants like dust (and many others) are generated due to various space activities and processes. It’s generally understood how dust particles will fall from the air under gravitational influence and land on top of any horizontal surface it contacts. When this occurs, it requires these accumulations be physically removed through some type of manual cleaning intervention. But most of us have also noticed how other surfaces (not in the particles' direct vertical fall plane) like ceilings, walls, computer screens, etc., can also collect airborne contaminants. Electrostatic Attraction (ESA) is an occurrence that results in the attraction of airborne dust and contamination on surfaces of all types, in any orientation, and is something that must be controlled within the environment.

Adsorption is viewed as a surface phenomenon and is the process by which one substance is attracted to and held on the surface of another. It is usually described in terms of surface energy per unit area of a solid. Atoms and molecules are held together in a solid by physical forces as strong as valance (chemical) bonds and as weak as van der Waals (physical) attractive forces. Molecules in the interior of a solid are surrounded by identical molecules and are subjected to equal attractive force on all sides. Surface energy is caused by molecules in the surface layer which are subjected to unbalanced external forces.

However, these attractive forces do not stop abruptly at the surface. Instead, they extend outward from the surface, and when this surface energy is strong enough to overcome the kinetic energy in a passing molecule, that molecule is adsorbed by the solid. Adsorption can occur whenever a material has sufficient attractive force to overcome the kinetic energy of another molecule. For instance, the adsorption of cigarette smoke on the interior of an automobile or on a person’s clothing is one example of how widespread this process is.

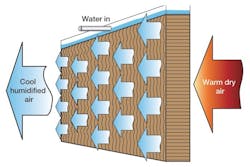

Figure 2. Force of Attraction

Molecular attraction helps keep dust particles attached to a surface, and the bond between the surface and particle depends on several forces of attraction. Most molecules, even when they carry no charge, have a dipole moment. This happens when there is more of a concentration of electrons at one point or end of a molecule than there is at the other. This is especially true of large molecules.

As a result, when a particle (even when its charge may be electrically neutral) encounters a surface, it tends to align itself so the more negatively charged side of the particle is adjacent to the more positively charged sector of the surface. Neither the particle nor the surface must be charged for this to occur. Another consideration is van der Waals force, which is the same force of molecular attraction that helps keep a dust particle attached to an air filter fiber.

This phenomenon results in the “plating” of particulates from the air, on to various surfaces, and results in an array of concerns within environments of all types, particurally those requiring that product or processes be maintained at pristine levels of cleanliness to achieve a proper outcome.

As a single but serious example, think of bacterial-laden skin squames (skin flakes sluffed off by humans) that become suspended in the air of a hospital operating room during a procedure (viral and fungal contamination also can be present in these skin scales). These pathogens can then plate-out onto sterile surgical equipment, instruments, or devices, which are then inserted into the body of a patient.

Even the garments worn by staff are susceptible to this unwanted accumulation of contaminants which can easily be transferred to the patient. Clinical trials carried out in Britain, Europe, and the U.S. have confirmed that between 80% and 90% of bacterial contaminants found in the wound after surgery come from colony-forming units (cfu) present in the air of the operating theatre.

Effective grounding provides a path for static electricity to discharge safely, and in many cases proper grounding solves the bulk of problems. But bonding of personnel and surfaces as a means of static control in a clean room is very difficult to accomplish. As well, the average clean room facility is not equipped with static measuring devices, and the clean room operator usually does not recognize that static precipitates dirt (dust) like a magnet, and that it is virtually impossible to eliminate without preventative measures.

Space humidity control, typically to achieve a relative humidity of 40% to 60%, offers balanced levels that safeguard against overly moist or dry conditions, protecting against unwanted issues such as ESD, shrinking, cracking and other forms of product damage. As a result, clean room product quality is increased and maintained more consistently. Humidifiers have been used in less sensitive environments to help drain off static charges by coating surfaces with a thin layer of moisture.

But the growing requirement and specific demands from various industries may require extremely low environmental moisture levels, often necessitating dew point temperatures far below the freezing point to prevent damage to sensitive components which might corrode in storage or where moisture might condense on these parts, for example, those used in space vehicles operating at cryogenic temperatures.

Figure 3. Humidification

Electrical phenomena can act as major transport and removal mechanisms for submicron particles. Over 90% of airborne particles indoors may be less than 1 micrometer (μm) in size, a size-range occupied by many potential pollutants, carcinogens, pathogens, and other potentially harmful contaminants. The behavior of the smaller particles within this range is greatly influenced by their electric charge. Along with more passive approaches, artificial means of ionizing the clean room air has been used for decades to help control space electrostatic issues.

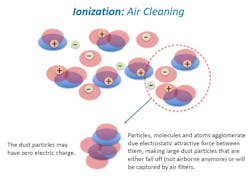

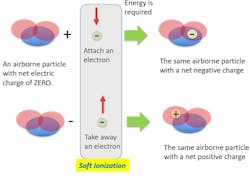

Ionization technology works by making air (normally an excellent insulator) conductive. Bipolar Ionization (BPI) creates large quantities of both positively (+) and negatively (-) charged air ions that are attracted to the opposite polarity charge located on product, equipment, or a materials surface. It effectively neutralizes the charge on surfaces of insulating materials, dissipating existing charge and limiting the potential of charge generation.

Figure 4. Bipolar Ionization

Electrical ionizers generate air ions by intensifying an electrical field on a high-voltage tube (corona discharge BPI), on emitter pins, or carbon fiber brushes (needlepoint BPI). This energy causes electrons to separate from the nucleus of the air molecules. It’s important that concentrations of air ionization within the space be precisely controlled to include an equal number of positive and negative ions, providing an intrinsically balanced output that is then distributed in a relatively homogeneous manner throughout the area of the clean room.

While not only serving to help defuse surface-related ESD issues, ionization also assists in helping remove particles from the air. This can drastically reduce the quantity of airborne particulate available to plate-out on surfaces, devices, and even on to occupants, helping eliminate potential contamination concerns.

Agglomeration of small airborne particles occurs in an environment with moderate to high levels of bipolar air ionization, whether imparted by nature or artificially generated by ionizers. When ions are artificially generated, they can be released and distributed throughout the space to mix with air and attach electrostatically to airborne particles. In similar fashion to how magnets of opposite polarity are attracted to each other, these charged particles are then increasingly attracted and joined to one another. Their size and weight is increased to the point where they are larger, and heavy enough to be more easily and quickly transported out of the space, with the ventilation system’s airflow.

They can now be more effectively removed from the air to be exhausted, filtered or treated. Air filters are more successful at removing these larger particles from the air, while internally mounted ventilation system air purification devices (if installed) can now address the pollutants they have been tasked with remediating, those which before had been difficult to remove and had remained in the space as an issue of concern.

Figure 5. Particle Agglomeration

Bipolar ionization of the air has been used in cleanroom applications to help reduce airborne particle counts and create cleaner indoor environments for critical pharmaceutical, healthcare, semiconductor, food processing, and various manufacturing processes for decades. Studies have demonstrated that air ionization is effective at removing aerosols and particles from the environment, providing significant reductions in indoor particulate concentrations. Bipolar ionization has also been tested and shown to be effective at both increasing the filtering rate of aerosolized pollutants, as well as increasing the decay of certain viruses and pathogens as verified in BSL3 laboratory testing.

Even so, it should be cautioned that the high voltage production of ionization (known as hard ionization) can create ozone which has human health hazard concerns. Equipment used therefore should be a form of electric ionization which incorporates relatively low voltage levels, yet produces high levels of bipolar ionization. In combination with proper air velocities, this can create a maximum ionization effect without the generation of harmful byproducts. Technologies which work on the principle of “soft ionization” are perfect for these applications.

As described by Hartley and Kanik, in their paper entitled “A Nanoscale Soft-Ionization Membrane: A Novel Ionizer for Ion Mobility Spectrometers for Space Applications,” soft ionization mechanisms do not fracture the target molecules, which could result in secondary byproducts such as ozone.

Figure 6. Soft Ionization

Clean room technology has proven effective in virtually eliminating human and process-driven particle contamination, vastly improving product yields in the manufacturing industry. While it’s understood that the aerospace, defense contracting, pharmaceutical, semiconductor, food processing, and laboratory industries may all require the sensitivity that a clean room environment offers, cost-effectively applying any of the design and application techniques described here might also help to make even those more traditionally built indoor environments cleaner, healthier, and more productive for the occupants inhabiting theses space.

With that in mind, it may make sense for society to place the same value on the air a building occupant breathes as it does on the products and services manufactured for their use and consumption.

##########

About the Author

David Schurk DES, CEM, LEED-AP, CDSM, CWEP, SFP, CIAQM, is the Director of Healthcare and Applied Engineering Markets for GPS Air in Charlotte, NC. He is a Licensed Designer of Engineering Systems and has over 30-years of experience in the design and analysis of heating, ventilating, and air-conditioning systems for a variety of market sectors, with a special focus on aerospace and healthcare facilities.

References

1. Jamieson, K.S.; ApSimon, H.M.; and Bell, J.N.B. 2008. “Electrostatics in the environment: how they may affect health and productivity.” Journal of Physics: Conference Series 142;

2. Howorth, F.H. 1985. "Prevention of airborne infection during surgery." Lancet. 325: 386-388;

3. Pearsall, D. 1966. “Distribution of ions by air for effectual control of electrostatic charges.” ASHRAE Journal;

4. Schurk, D. 2021. “A Bipolar Ionization Primer for HVAC Professionals.” ASHRAE Journal;

5. National Air Filtration Association, NAFA Guide to Air Filtration, Sixth Edition, 2021;

6. Farahi, F. 2021, Application of Soft Ionization in Improving Indoor Air Quality, Department of Physics and Optical Science, The Optics Center University of North Carolina at Charlotte;

7. Galatowitsch, S. 2020. “Terminating Static in the Cleanroom”. Semiconductor Digest;

8. Integrated Circuit Engineering Corporation."Cost Effective IC Manufacturing 1998-1999, Section 3: Yield and Yield Management." http://smithsonianchips.si.edu/ice/cd/CEICM/SECTION3.pdf.