HVACR Technology Can Boost Supermarket Energy Efficiency

By LISA TRYSON and

TORBEN FUNDER-KRISTENSEN

Danfoss

Baltimore MD

Over the last two decades, advances in HVACR technologies have produced significant improvements in energy efficiency. During that time, residential HVAC systems in the U.S. have gone from 10 SEER to 15 SEER, a 25 percent efficiency improvement. For commercial buildings, the source and site-energy-use efficiency improvements in ASHRAE 90.1 standards have increased more than 40 percent, with corresponding reductions in CO2 emissions.

What about supermarkets? HVAC and refrigeration equipment use 50 to 60 percent of all electricity a store consumes. Given the leaps in residential and commercial efficiency, it’s reasonable to ask: “Can HVACR technology cost-effectively boost supermarket energy efficiency and further reduce emissions in the future? Or, are we approaching a technological limit where efficiency gains will demand extraordinary investments—investments that may have a better payoff elsewhere in the facility?”

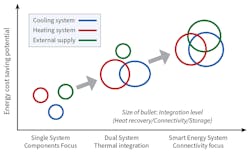

To get answers, it’s worth examining different areas where supermarket efficiency improvements are possible: components, systems and connected systems within the store. Looking beyond the store, it’s clear supermarket owners can achieve higher energy savings and faster ROI by aggregating thousands of energy-consuming devices used in multiple stores. To manage that array of technologies, however, supermarket officials need advanced energy-management controls and services that can be deployed within the tight budgets they traditionally work with. As will be shown, intelligent controls that connect with devices and systems inside and outside the store can produce opportunities for substantial energy savings and energy cost reductions.

Incremental efficiency improvements inside the store

Along with residential and commercial HVAC applications, supermarkets can also take advantage of improved efficiency in components and systems.

Technological advancements have resulted in numerous efficiency improvements. For example, the introduction of NEMA Premium® efficiency motors for compressors help reduce energy consumption. In heat exchangers, advanced design reduce the refrigerant charge while increasing the heat transfer ability. Another example is the application of variable-frequency drive (VFD) technology. In a refrigeration system, the typical compressor rack employs multiple fixed-speed compressors. When a VFD and related controls are applied to one of those compressors, that compressor can reduce energy consumption by modulating its speed to match the refrigeration load more precisely. For mid-range rooftop HVAC equipment that supermarkets use for space cooling, a VFD can cut energy consumption by reducing compressor motor speed during 99 percent of operating hours when full cooling capacity is not needed. And applying VFDs may also help the store qualify for utility incentives.

More energy can be saved by using advanced controls. For example, implementing advanced superheat case control in the refrigeration plant boosts system efficiency by ensuring the evaporator is optimally charged, even when the load and suction pressures vary. Case control can also provide an adaptive defrost function that skips the energy-consuming defrost cycle when not needed. In CO2 racks, as an example, gas ejectors paired with advanced control algorithms can save close to 12% of system energy consumption on an annual basis. These devices exploit the work lost during initial expansion of the CO2 that otherwise would be regarded as a loss. As another example, liquid ejectors are being developed to pump liquid exiting from evaporators in CO2 systems and will be able to adapt to specific working conditions to better utilize evaporators. In both examples, the captured energy will result in less compressor work and, thereby, more energy savings.

At the store level, energy savings can be even more substantial than the efficiency gains that accrue from improving components and systems alone. But to get bigger savings, technologies must be employed that can manage and monitor all major energy-consuming appliances in the store.

The concept behind holistic store energy management—implemented in the Danfoss Smart Store solution—is that managing everything together saves more energy than optimizing components and systems individually. With Danfoss Smart Store technology, communication between all components is directed to a central hub, the system manager. Functioning as the “brains” of the system, a Danfoss System Manager exchanges data with individual refrigeration controllers and optimizes suction pressure, defrosting and other critical refrigeration functions. A single system manager can also manage lighting and HVAC.

The result is an integrated solution that unlocks the full potential of each device and increases the efficiency of the entire store. Depending on prior energy-consumption levels and scope of implementation, this has achieved from 10 to 50 percent annual energy savings. The solution also simplifies equipment monitoring, HACCP reporting and other management functions, which reduce labor costs.

At a strategic level for the entire store, it’s possible to make decisions that take advantage of major energy-saving developments. For example, more and more store owners are making a strategic move to CO2 refrigerant. For years, CO2 has been recognized as the greenest, most environmentally-friendly refrigerant due to an ozone depletion potential (ODP) of zero and a global warming potential (GWP) of one. But, because of high pressure levels and relatively high implementation costs, CO2 has rarely been considered a cost-effective option, especially in warmer climates.

Now, CO2 has become cost-effective—even in warm climates—due to two technological developments: Multi-Ejector and compatible pack controller technology engineered by Danfoss to optimize the warm climate performance of a CO2 system. When applied in a transcritical CO2 system, Multi Ejector technology can reduce energy consumption from 9 to 18 percent compared to R404A systems. Additional savings are available when a CO2 booster system is used for heat reclaim. Heat reclaim boosts the seasonal performance factor (SPF) and the coefficient of performance (COP) of the system above most heat pumps of similar capacity. Stores can take advantage of heat reclaim to produce hot water for cleaning, food prep and lavatories. For example, an innovative store in Carol Stream IL is using the hot water for under-floor heating in walk-in freezers.

Efficiency improvements through connectivity

Improving energy efficiency inside the store is not the only way to boost energy savings and reduce environmental impact. Certainly, optimizing equipment, systems and the whole store are worthwhile.

However, even bigger energy savings can occur when technologies and services make connections outside the store. In fact, managing multiple stores across the enterprise multiplies the energy savings.

To get actionable, real-time data, supermarket staff responsible for energy management need technology that can collect from connected devices a wide range of data points encompassing refrigeration, food safety, HVAC operation and energy management.

That may sound extremely complex. That’s because the technology must be able to interface with every major energy-consuming device in a store, then aggregate all the data from every store to get a complete picture of what’s going on.

Fortunately, making those connections can be accomplished relatively easily and cost-effectively. Regarding its technology, for example, it’s a matter of accessing intelligence already built into Danfoss system managers. In addition, they have the ability to communicate with third-party control systems.

Of course, many supermarket operators already use a central management controller that connects multiple cooling cases, compressors, lighting, etc. However, using sensors, software and connectivity devices embedded with an “internet of things” (IoT) level of intelligence can deliver a higher level of energy savings. Smart, connected technology can collect and exchange data over the internet remotely at all hours. Consequently, it can communicate with applications and services in the “cloud” to enable data-driven decisions.

Using a cloud-based service delivery platform, supermarket energy staff can get powerful insights into individual and collective store performance. As far as conventional alarm reporting and 24/7/365 alarm notifications, it displays relevant data in a graphical dashboard for fast diagnostics via a web browser or mobile device.

Danfoss Enterprise Services (DES) can also perform strategic functions such as:

• Hazard Analysis and Critical Control Points (HACCP) reporting to verify temperatures meet regulatory food safety standards;

• Temperature Quality Index (TQI) graphical summary of display case, cold room and HVAC temperature performance;

• Energy performance and modeling with baselines and benchmark reports for refrigerant and HVAC equipment to compare current and past performance;

• Inter-store benchmarking to compare store rank and spotlight areas to improve efficiency, and also verify setpoints and compare alerts to reveal trending issues and opportunities.

Looking at the big picture, enterprise-level services deliver real-time device-level, system-level and building-level information that enables a “big data” approach to analyzing store performance. Such services empower facility personnel, store owners and management to make fast decisions to maximize energy efficiencies and cost savings, optimize food safety, and reduce the store’s environmental footprint. It can also improve the shopper experience by creating a more pleasant environment with optimum lighting, humidity control and ventilation.

Energy costs can be cut via incentivized utility programs

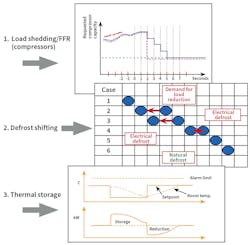

There are even more rewarding ways to save energy beyond optimizing the energy performance of multiple stores in the enterprise. Substantial energy cost reductions can be achieved by leveraging the intelligence inside Smart Store technologies to connect with “demand-response” and “load-shedding” programs offered by utilities.

In recent years, many utilities have offered programs to incentivize customers to cut electric consumption when power demand is high. During those periods, utilities want to avoid buying power from competitive utilities or firing up inefficient generating equipment. When utilities can avoid these expenses, they pass on the prospective savings to participating customers in two ways:

1. Demand Response (DR) Payments are paid by curtailment service providers (CSPs) to supermarkets that agree to reduce electricity use (load) in response to a particular, temporary event. Customers get paid in cash or credits for participating in the program and for responding to events—for example, turning off lighting and non-critical equipment during a DR event. With proper controls and safeguards, it’s also possible for 20 to 40 percent of cooling capacity to be reduced for up to 20 minutes to allow compressor load shedding in response to specific grid requests.

2. Peak-Shaving Incentives often take the form of lower time-of-use (TOU) rates for supermarkets that shift some of their electric load away from peak periods. The cost savings from peak shaving can double what a supermarket receives in DR payments.

Several tactics can be used. They include:

* Load shifting can be accomplishing using several different tactics. For example, mechanical equipment for cold rooms, can operate outside peak periods when utility rates are lower, so equipment runs less often during peak hours when rates are high. Of course, close temperature monitoring is required to ensure quality. Another approach is to charge a thermal storage system during off hours and discharge during peak demand periods to minimize running mechanical equipment.

* Load displacement is another tactic that cuts peak demand by using on-site generation, such as solar or wind, instead of using electricity from the grid.

Many utilities in the U.S. offer DR programs that supermarkets can participate in. To realize the benefits, the store must have the flexibility to curtail or shift its power demand. Once again, Danfoss Smart Store infrastructure easily implements these programs by tapping the intelligence and connectivity built into system managers. No hardware or software retrofit is needed.

The infrastructure is scalable across large, multi-location food retail chains. For DR and peak shaving, the supermarket’s energy official works with CSP and DES to enroll particular stores in the program. The agreement can define multiple tiers of power reductions for light and HVAC, for example.

When the CSP notifies supermarket officials that a DR event is occurring, the official informs DES about the response tier and the specific stores participating in the event. Then, DES initiates the response by communicating over the internet to the system managers in the selected stores. A single Danfoss AK-SM 880 System Manager can serve as a full-store controller for lighting, refrigeration compressors and HVAC equipment. At every point, internet communication is fully encrypted. Smart Store connectivity and intelligence enables DES to implement the load reductions without the individual store manager or shoppers needing to know.

Connectivity opens other possibilities for energy savings

Using smart devices that connect to energy management services and demand-response programs are cost-effective ways to cut energy costs now, and also offer the possibility of connecting to the “smart energy grid” of the future.

The smart energy grid also encompasses thermal grid services and uses dedicated thermal storage devices. In many malls or cities, it is possible to connect the thermal networks of the buildings to share heating or cooling capacities. Most HVACR systems are dimensioned to cover extreme peak load situations often utilizing below 50% of the installed capacity. That available capacity can be utilized to store cold or heat when electricity prices are low. While merging electricity and thermal management in shared grids seem futuristic, they are piloting in several areas in Europe. Danfoss has developed specific heat recovery units to facilitate adoption to thermal grids. The basic disciplines becoming mainstream include:

* District heating and cooling (DHC). Employed for decades in large urban centers and campuses, a DHC system distributes hot and/or chilled water that is piped underground to individual buildings within a defined area. The heating and cooling of the network is done at central or decentral suppliers. Applying the DHC strategy to incorporate thermal processing plants, like supermarkets, makes it possible to supply excess refrigeration/cooling capacity to adjoining stores through DHC piping. The outside stores can then cut back on mechanical, allowing them to pass on a portion of their electricity savings to the supermarket as a revenue stream.

* DHC utilization of heat recovery. As previously discussed, a transcritical CO2 booster system can produce heat that a store can use. In fact, the exit temperature of CO2 gas can be as high as 175°F (89°C) and, even more importantly, it contains useful high energy levels at high temperatures. At that temperature, the thermal energy in the hot gas can supplement or replace the heat generated by an oil or gas boiler. Surplus heat generated by a CO2 refrigeration cycle can be supplied to other stores through a DHC system. In Europe, a mid-sized supermarket is benefitting from a revenue stream ranging up to $9,000 annually by selling the heat to other stores. The heat supplied by the compressor reduces the store’s cost of heating hot water. In 2018, the Danfoss “recovering heat from CO2 refrigeration systems” solution was awarded the Solar Impulse Efficient Solution Label by the World Alliance for Efficient Solutions, based on an assessment made by independent experts.

Conclusion

The key to boosting supermarket energy efficiency is unlocking the potential of cost-effective HVACR technology that has intelligence and connectivity embedded at all levels of the store. Smart HVACR devices and local controllers boost efficiencies in equipment and systems. At a higher level, Danfoss Smart Store system managers optimize the performance of all appliances and lighting. But, substantial energy savings really start to add up when Smart Store intelligence connects with enterprise management and utility programs. At the highest level, maximum savings—even new revenue streams—can be obtained by connecting with DR programs and DHC systems.

At every level, boosting energy efficiency involves more sophisticated control technologies. Embedded intelligence and cloud connectivity facilitate system optimization, store operations and energy strategies that really pay off. However, it takes early consultation and expert guidance in the planning process to identify cost-effective solutions that can provide rewarding energy savings today--plus, a realistic ROI that will keep supermarkets competitive in the future.