Right-Sizing Your Boiler Plant Will Optimize System Operation

By ANDREW MACALUSO and THERESA D'AMORE

When designing a boiler plant, key factors must be considered. The physical layout must fit in the space allotted yet provide room for maintenance technicians to work. A focus on piping, controls, and support equipment can help reduce fuel and maintenance costs. It is also critical to correctly size equipment to prevent excessive cycling for a long operational lifespan.

Design Selections

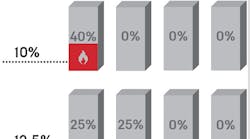

The first decision is the number of units to meet the heating load. A good goal is 3-5 heat exchangers. An ideal boiler plant will have a minimum of two units for the heating load, and a third for N+1 redundancy. To reduce the size of the “redundant” boiler, a 3+1 or 4+1 plant can also be installed. In these cases, the redundant boiler will be 33% or 25% of the design load and may reduce the initial equipment costs while maintaining plant capacity and redundancy (figure 1). Using different equipment sizes can also be effective.

There is a diminishing return to increasing the number of units due to maintenance costs and larger space requirements. A 3+1 plant requires a “redundant” unit at 33% of plant capacity, but a 6+1 design will only require a redundant unit at 17% of plant capacity. The drawback is that the maintenance cost of seven units is much higher than that of four units.

Another solution is to use a “modular” boiler to increase plant redundancy. These boilers provide a complete boiler plant in a single enclosure with one set of gas, water and flue connections.

The appeal of a modular boiler is that each unit has the redundancy of a multiple-boiler plant. Designing these plants has the same considerations as larger plants; a target of 3-5 total heat exchangers is considered ideal. Modular boilers are best applied in light-commercial applications that may only have space for one or two units. When installing only one modular unit, it’s important to understand that the unit will need to be powered down for maintenance and other work; critical facilities should always install a redundant unit to ensure uninterrupted heat supply.

After selecting equipment, designers should review piping, venting and controls. Considering these items up front will prevent schedule overruns and costly change orders. A common mistake is to overlook exhaust and supply air needs until the equipment arrives for install, at which point there may be no way to safely route the exhaust, leading to cost and schedule overruns. Venting deserves a close review, as requirements can vary greatly.

Installation, Footprint Considerations

Once the boilers are sized and the number of units determined, they must be laid out in the mechanical room. When doing so, be careful not to gain floor space by sacrificing serviceability!

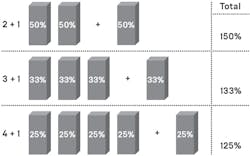

While it may look nice on a drawing to have units only a few inches apart, servicing them becomes a challenge. Provide as much space as possible between units. When room is unavailable, some manufacturers will allow for “zero-side clearance” wherein a boiler is placed directly next to a wall or adjacent boiler. A good rule of thumb is to only use zero-side clearance on a single side and keep the other side available for service (figure 2).

Once the boilers are in place, ducting, gas and water piping, electrical conduit, and communications cables must be run. Other equipment in the mechanical room, such as overhead heaters, are factors, as well. It’s important to understand the equipment’s overhead clearance and how much open space must be provided.

Another variable is how the boilers will be maneuvered into place. New construction has options, as the boilers can be placed before walls or ceilings are installed. However, if equipment is not delivered on time, there may be project delays. Costs can add up rapidly for every single day one aspect is on hold and must be considered.

Retrofits have different challenges. If equipment cannot fit through existing hallways and doors, a wall may need to be demolished and rebuilt, or a ceiling opened and later repaired. For penthouse installations, if the boiler cannot fit in an elevator, or is too large to be rigged up a staircase, a construction crane, and its associated costs, may be needed.

Retrofitting to Condensing

With altering existing systems, the opportunity exists to completely overhaul a system. But will the budget allow it? These simple changes to piping, pumping, or controls can create savings:

• Temperature reset will improve equipment efficiency and lower fuel costs. This applies to outdoor or seasonal resets, as well as night and weekend setback schedules;

• Tuning the system supply temperature is very effective in reducing cost without impacting occupant comfort;

• Slowing water flow in conjunction with a lower temperature supply saves on pump energy and fuel cost. As flow rate is inversely related to the ΔT, lowering it will lessen return water temperature and increase efficiency;

• If an existing system utilizes primary-secondary piping and building demand is upward of 1MMBH, converting to a primary-only arrangement will lower operating costs. It must be noted that water tube heat exchangers should only be installed in a primary-secondary system to protect the heat exchanger from ∆Ts greater than their design allows.

Turndown Importance

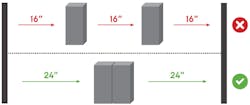

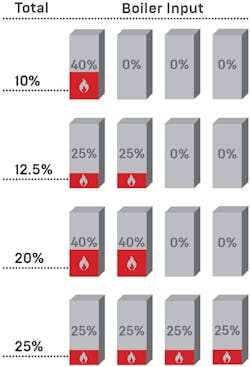

Excessive cycling will increase energy costs and unscheduled maintenance, and lower mechanical equipment life. The easiest way to prevent cycling is to select equipment with sufficient turndown. When installing multiple boilers, the turndown is “added” among the boilers, as the input can range from all units at maximum fire down to a single model at minimum fire.

Turndown is crucial because boiler plants are designed for the coldest days of the year. These “design days,” however, account for <1% of the total boiler runtime. Most of the time (>50%) the boiler plant will be operating at a significantly reduced input during the colder months. Since condensing boilers are more efficient at lower firing rates, having a high turndown will translate directly to fuel savings.

Boiler Mass Myth

There is a misconception that cycling can be prevented by using a high-mass condensing boiler. Typically, non-condensing boilers with Scotch-Marine or cast iron designs are considered high-mass compared to models with “low-mass” stainless steel, copper, or aluminum heat exchangers. Some designs, such as larger condensing stainless steel boilers or condensing cast-iron boilers, may be described as “mid-mass.”

What defines the need for a buffer tank is the thermal mass present in the heating system (including the boiler), minimum system load, minimum boiler cycle time, and boiler plant turndown. The only impact boiler mass will have is in the recommended minimum cycle time.

Sequencing and Lead Boilers

How a boiler plant is sequenced and modulates firing rate can impact operational costs and system longevity. Upon call for heat, a single boiler will fire. This is typically known as the “lead” boiler, and the last unit is termed the “lag.” In a multiple boiler plant, the lead boiler should rotate to balance the total run hours and number of cycles on each unit. This results in fewer unscheduled service calls and less frequent component replacements. It will also simplify planning end-of-life replacements.

Generally speaking, high-mass boilers are more efficient at full fire than at part load. Conversely, it is not uncommon for condensing and mid- or low-mass boilers to have very low jacket losses of <1% and even <0.1%. Since the heat exchanger surface area is fixed, lower firing rates mean better heat transfer into the heating loop and higher efficiencies at lower firing rates (figure 3). These systems typically operate to maintain as many units at as low of a firing rate as possible without causing undue cycling.

Putting It All Together

An ideal boiler plant will have enough heat exchangers to provide reliable operation and sufficient system redundancy, without adding excess maintenance costs. Boilers should be selected with an eye towards ease of installation and footprint, and with high enough turndown to prevent cycling during low loads. Boiler controls should rotate lead boilers and sequence multiple boilers for operation and service benefits. By balancing all of these factors, an efficient plant can be designed to maximize heating efficiencies while reducing maintenance and installation costs.

Both authors are engineers. Based in Boston, Macaluso is Product Solutions Manager for AERCO International. Based in NYC, D'Amore is Manager, Systems Engineering, at Watts Water Technologies.