By DANIELA BILMANIS, Johnson Controls, York County PA

Consulting engineers and building owners are seeing that new centrifugal chillers optimized for next-generation refrigerants offer real advantages for present-day applications.

Compared to the HFC refrigerants they are beginning to replace, next-generation refrigerants — which include HFOs and blends — have no ozone depletion potential (ODP) and a much lower global warming potential (GWP) as low as 1.0. That’s good news for strategic decision makers who want to make an environmentally friendly, “one-and-done” chiller selection.

Several factors come into play when selecting next-generation refrigerants for chillers:

- Flammability: Only a few next-generation refrigerants for centrifugal chillers are classified as non-flammable. This is a real challenge for building owners and contractors who don’t usually have to think about refrigerant flammability with current refrigerants. Fortunately, several low- and mid-pressure next-generation fluids have non-flammable ratings.

- Toxicity: Almost all next-generation refrigerants have an “A” low-toxicity rating similar to currently used HFC R-134a. However, there is one proposed alternative, R-514A, that has a “B” toxicity rating, because it exhibits similar moderate levels of toxicity as HCFC R-123.

- Refrigerant cost: Next-generation refrigerants can be more expensive to manufacture than current refrigerants. This expense is not an issue if the chiller is optimized to produce energy and operational savings that produce a fast payback.

Optimization a team effort

Optimizing a centrifugal chiller for next-generation refrigerants requires the chiller design team to rethink every component on the chiller. For the Johnson Controls design team, the goal was to optimize a chiller for R- 1233zd(E), a low-pressure fluid with a flammability rating and GWP of 1.0.

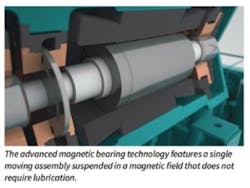

The team used a holistic approach to system design and engineering, optimizing every component around this next-generation refrigerant’s performance characteristics. The result is the YORK YZ Magnetic Bearing Centrifugal Chiller — a water-cooled, single-stage design employing a variable-speed compressor driven by a hermetic induction motor using active magnetic bearings. The advanced magnetic bearing technology features a single moving assembly suspended in a magnetic field that does not require lubrication. This technology requires 80% fewer moving parts than traditional oil- or refrigerant-lubricated drivelines.

To deliver significant energy savings and lower operating costs with R-1233zd(E), the YORK YZ takes advantage of off-design conditions where chillers operate 99% of the time. The intelligence built into the driveline enables stable operation over a very wide operating envelope. The compressor can handle entering condenser water temperature (ECWT) as low as 40°F (4.5°C) compared to the 65° F (18° C) limitation with conventional, oil-lubricated chillers. Fully modulating control can adjust capacity from 100% to 10% of design load, while handling leaving chilled water temperatures (LCWT) from 38°F (3.5°C) to 70°F (21.0°C).

As implemented in the YORK YZ chiller, the compressor and control technology can even operate when the entering condenser water temperature is below the leaving chilled water temperature. This capability — known as inverted operation — eliminates the need for a water-side economizer, thereby simplifying the system and saving money on components, piping, controls and maintenance.

The stability provided by advanced compressor control eliminates the need to modify building control strategies to prevent surging and stalling that affect conventional centrifugal chillers at extreme conditions.

Because every component on the YZ was chosen to provide the widest operating map possible, the chiller can respond to changes in the building load throughout the year and always operate at the most efficient point possible. Compared to traditional fixed-speed oil-bearing chillers, the YZ potentially delivers up to 35% annual energy savings. Moreover, a falling film evaporator was employed that reduces evaporator shell size up to 20% and refrigerant charge by as much as 60%.

Centrifugal chillers can deliver significant energy savings and lower operating costs by taking advantage of the off-design conditions where chillers operate 99% of the time. Every component on the YORK YZ was chosen to provide the widest operating map possible so that the chiller can respond to changes in the building load throughout the year and always operate at the most efficient point possible.

No place like home

The performance improvements due to these design decisions are showing up in the field.

For the Johnson Controls corporate campus in Glendale WI, a YORK YZ chiller has been operating for nearly a year. Ultra-high-efficiency comfort cooling is critical for this facility. The Glendale campus represents the largest concentration of LEED Platinum buildings on one site ever awarded.

In one 385,000-sq-ft facility used by 1,500 professionals, a nominal 350-ton YORK YZ chiller provides comfort cooling for office and laboratory environments. The ambient conditions are typical for Milwaukee, Wisconsin, with design-day conditions of 86°F (30°C) dry bulb, 72°F (22°C) wet bulb and a 72°F (22°C) dew point. Indoor temperature setpoints are 70°F (21°C) in winter and 74°F (23°C) in summer. The YORK YZ took advantage of these conditions by operating with an entering condenser water temperature (ECWT) of 68°F (20°C) and leaving temperature of 58°F (14°C) using just 0.236 kW/ton, which is 60% of full load kW/ton.

That level of performance reinforces a corporate commitment to excellence in triple-bottom-line indicators of economic, social and environmental impact. It is also evidence that next-generation centrifugal chillers will make a significant improvement in energy, operating and maintenance costs to customers going forward.

The author is product and strategy manager of Global Chiller Products at Johnson Controls. After earning a mechanical engineering degree at the University of Maryland, Bilmanis joined JCI in 2010, where she is now focused on new product development.