What Owners Need to Know About ... Wireless Controls

Whether you are looking to add data points to your building automation system (BAS) for energy monitoring/optimization, perform tenant improvements, or increase occupant comfort, now is an excellent time to transition to wireless controls. Consider:

- Many energy-service companies provide active 24/7 remote monitoring, energy-efficiency optimization, and energy-efficiency/deficiency reporting, highly sophisticated services requiring large amounts of data input. Running electrical wire for traditional control solutions costs money, takes time, and can be intrusive to occupants and disruptive to operations. Wireless controls can significantly reduce this expense, time, and inconvenience.

- Since the economic downturn of 2008, flexible floor plans have played an increasingly large role in tenant-recruitment/retention efforts. Wireless controls can help with the associated costs.

- In large areas, such as office spaces with cubicles in the center, we often see traditional thermostats placed on the perimeter because of difficulties installing the wiring elsewhere. Temperature readings taken at these locations do not represent the true zone temperature, only local temperature, which almost ensures there will be hot or cold spots across the larger area. Wireless technology allows thermostats to be located in the center of spaces for more precise zone control. What’s more, multiple wireless thermostats can be installed to average the temperatures throughout a space. With traditional wired thermostats installed on the perimeter of office spaces, we have seen occupants complain they are cold in the summer and warm in the winter. With wireless technology, thermostats can be located in each office, allowing the BAS to see the temperature in each zone and make appropriate changes. When temporary walls are used, it is more difficult to get a thermostat wired into each office. Wireless thermostats can be mounted anywhere in a cubicle area. The BAS can look at a single thermostat or multiple thermostats and average to decide what to do in the zone. This improves occupant comfort and avoids overcooling/overheating.

So far, we have discussed existing buildings. Even if you are evaluating wireless controls for new construction, planning with wireless controls can save time and money. In new construction, the difference in cost between wireless controls and wired controls often is negligible; however, selecting equipment with factory-mounted and pre-programmed wireless devices will save installation and startup labor costs. Looking into the future, tenant improvements and technology advancements are inevitable. Tenant-improvement costs can be reduced when using wireless controls. Plan for these changes by using wireless controls on variable-air-volume boxes, fan coils, and thermostats. For new construction, the increased cost of wireless equipment, wireless receivers, etc. may provide only a small overall cost reduction after considering wiring equipment/labor costs. When this situation arises, looking at costs incurred in the future will further expose the value of going with a wireless system. There often are changes during the construction process as well. These changes are costly and can delay critical deadlines. Starting your building off with wireless controls could help you mitigate the costs associated with those future changes during the design process or later in the building’s life. Also, with the increased use and production of wireless equipment, the cost is only going to go down.

In past years, proprietary protocols have been used on wireless communication products. These protocols tie a building owner to the controls company used. This is a throwback to the early days of direct digital controls (DDC), which did not provide happy memories for many customers. There are many building owners with painful experiences dealing with proprietary control protocols. In this scenario, the cost of service is set by the DDC company, and the owner’s only options are to pay up or rip out the controls and start new with another company. This is where ASHRAE stepped in and came up with ANSI/ASHRAE Standard 135, BACnet - A Data Communication Protocol for Building Automation and Control Networks. This standard allows multiple companies to operate in the same system by using a common protocol unlocking the building owner from one controls company and allowing fair market competition. There are only a few companies/alliances providing a completely BACnet-certified product.

The leading wireless-transmission network protocol for buildings is ZigBee. ZigBee is a trademark of the ZigBee Alliance, a non-profit association of manufacturers. This alliance regulates the ZigBee standard. Navigant predicts, “Wireless standards such as ZigBee and EnOcean will gain market share at the expense of proprietary solutions as demand for interoperability further develops.”1EnOcean is a trademark of EnOcean GmbH, which is an open transmission network protocol following its own standard (to clarify, ZigBee and EnOcean are different and separate from BACnet). Both ZigBee and EnOcean will provide a system allowing multiple companies to service their controls.

Battery life in sensors has been improved in recent years to the point replacing batteries no longer is an issue. A 15-year battery life for a multisensor (temperature and humidity) is available today in some ZigBee-certified systems. Fifteen years is the expected life of many equipment items used in commercial office buildings, so wireless controllers can be replaced or even reused when equipment is replaced. For products using the EnOcean technology, there are no batteries; devices, rather, are powered by proprietary technology called “energy harvesting.” This has increased the reliability of wireless networks by limiting the downtime of wireless sensors, along with reducing service costs.

Inevitably, the topic of security comes up with wireless networks, but products such as ZigBee and EnOcean have addressed this head on. For example, many ZigBee products use Advanced Encryption Standard (AES) 128 to secure their network. AES-128 “is a symmetric block cipher used by the U.S. government to protect classified information and is implemented in software and hardware throughout the world to encrypt sensitive data.”2 A BAS can be separate from the information-technology (IT) system for a second layer of protection against cyber threats. ZigBee products also adhere to IEEE 802.15.4, IEEE Standard for Low-Rate Wireless Networks, to ensure the wireless system does not interfere with other wireless systems on site. To ensure there will be no issues, it is recommended to consult with a wireless manufacturer. There are thousands of network-reliable and secure wireless installations where Wi-Fi and Bluetooth (arguably the two most well-known wireless protocols) networks co-exist with ZigBee and/or EnOcean networks in buildings as diverse as hospitals, schools, office buildings, prisons, and athletic stadiums.

Our world, our buildings included, is going wireless. Navigant Research projects: “The wireless control device market will grow steadily over the next decade. Revenue for wireless nodes will reach $434.0 million in 2023,”1 with lighting a major portion of the wireless nodes. Navigant says it is from increased lighting-control requirements and increased data required to be pulled from lighting. With HVAC seeing similar pressure from energy codes, using wireless controls on both can standardize a system. Standardization can reduce service costs, as the products and parts are similar. Many controls companies can tie together HVAC and lighting controls to a single front end for a simpler interface.

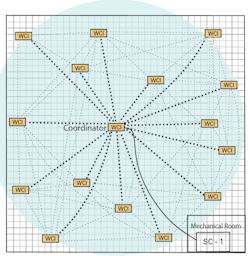

There are many arguments that wireless controls are more reliable than traditional wired systems. With wired systems, there are many points of potential permanent failure of communication wiring. If a network cable link is broken, whether from a shorted-out wire or a bad connection or construction damage, the communication is lost until identified and repaired. Because communication wiring is hidden in ceilings and walls, finding a communication break can be difficult and time-consuming. During the event of communication loss, HVAC equipment automatically goes back to its last setting before it lost communication with the front end, so all is not lost, but it will not take long for occupants to complain. With wireless systems, all of the wireless communication nodes become a wireless communication point. This means one wireless node can communicate with the front end through multiple paths. This is especially helpful when a communication link is lost. The system simply will find another path to the front end on its own. This often is called a “self-healing mesh.” See Figure 1 showing the communication paths of a typical office HVAC layout.3

In Figure 1, you can see each wireless communication interface (WCI) mounted on HVAC equipment. The blue circle represents the WCI coordinators (in the center) range of communication. If a WCI communication link is broken, there are many paths for each WCI to link up with to re-establish communication with the coordinator WCI. This process is automatic and takes no human intervention. In Figure 1, the WCI is wired to the system controller because the mechanical room is out of range and installing a single WCI coordinator is the cheapest option. The system will keep communication going without the occupant or operator knowing anything has happened. Alarms can be sent to the operator by setting the preferences in the front end to notify of a communication loss. This self-healing-mesh network is the core of the reliability argument. While the system has repaired itself to continue normal operation, the building operator has a significantly easier time pinpointing device failure than with a wired communication system.

Conclusion

There are many reasons to start the transition to wireless controls in existing buildings, whether you are adding more granular-data points for energy monitoring/optimization, performing tenant improvements, or wanting to increase occupant comfort. For new construction, it is a perfect time to start your building off with the technology of the future.

References

1) Freas, B., & Goldstein, N. (2014). Wireless control systems for smart buildings. Navigant Research.

2) Rouse, M. (n.d.). Advanced encryption standard (aes). Retrieved from http://searchsecurity.techtarget.com/definition/Advanced-Encryption-Standard

3) Trane. (2012). Best practices guide: Wireless comm network design. Retrieved from http://bit.ly/BAS-SVX55A-EN

Khalil Kairouz, PhD, PE, is associate vice president of Carollo Engineers Inc., an environmental engineering firm specializing in the planning, design, and construction of water and wastewater facilities. He has a doctorate in engineering and applied mathematics and has taught in the mechanical-engineering departments at Loyola Marymount University and The California State University. He can be contacted at [email protected]. Vincent Priolo, CEM, is an energy engineer with Trane who conducts training sessions on HVAC-system design and selection for consulting engineers. He has a bachelor’s degree in mechanical engineering from Cuesta College and a master’s degree in mechanical engineering from California Polytechnic State University-San Luis Obispo. He can be contacted at [email protected].