Supporting Your Seamless Shift to Low GWP Systems

Lennox is helping you prepare for HVAC projects in 2025 and beyond with everything your team needs to stay informed and competitive.

Across North America, the HVAC industry is converting to refrigerants with lower global warming potential. Our newly enhanced product lines are precision engineered for Low GWP refrigerants—and safe and reliable as ever.

Plus, we’re helping you navigate the road ahead with access to expert training, expanded online resources, and comprehensive support at every step, so you can convert with confidence.

Understanding the Transition to Low GWP Refrigerants

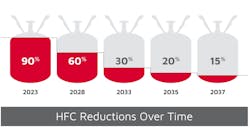

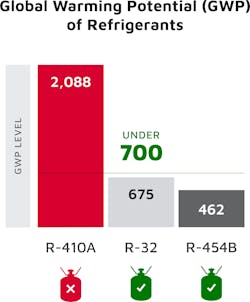

Beginning January 1, 2025, new HVAC equipment must use Low GWP refrigerants with a global warming potential under 700. This change stems from concerns over the environmental impact of hydrofluorocarbons, or HFCs. First popularized in the early 1990s as a replacement for older classes of ozone-depleting substances, HFCs do not damage the Earth’s ozone layer, but still contribute significantly to the greenhouse effect. As a result of the American Innovation and Manufacturing (AIM) Act of 2020, the U.S. EPA has a renewed focus on addressing the environmental impact of refrigerants. This has led to the adoption of new standards for heating and cooling equipment, phasing out refrigerants with a higher GWP, such as R-410A, in favor of more environmentally friendly refrigerants with a lower GWP, like R-454B and R-32.

Today, most refrigerant ends up in the atmosphere. According to the U.S. EPA, only about 15 million pounds of refrigerants are reclaimed each year, a small fraction of the 100 million-plus pounds put into use. The rest leaks from equipment or is illegally vented into the atmosphere. By replacing potent HFC greenhouse gases with Low GWP refrigerants, our industry can reduce the carbon footprint of HVAC equipment while helping commercial customers reach their corporate sustainability goals. Additionally, the shift to Low GWP refrigerants will reduce CO2 emissions by 4.6 billion metric tons between 2022 and 2050. It would take a forest more than two times the size of the continental U.S. an entire year to remove that amount of carbon from the atmosphere.

Identifying A2L Equipment and Refrigerants

To help identity A2L equipment, Lennox and other manufacturers have redesigned their HVAC systems to accommodate the new refrigerants, including safety features to address the mild flammability of A2L refrigerants. It’s important not to mix A2L with legacy refrigerants or equipment. Servicing tools and connections between R-454B and R-410A are not interchangeable. To help make sure the process is mistake-proof, there are several visual cues you can use to clearly identify A2L equipment and refrigerants.

A2L Refrigerant Storage Cylinders:

- Light gray/green canister. Red ring indicates a mildly flammable substance

- Must be labeled with type of refrigerant (e.g. R-454B)

- Left-handed threads (A1 refrigerants have right-handed threads)

- Pressure relief valve (A1 refrigerants have rupture disks) will only release the excess pressure needed to maintain the cylinder’s integrity to avoid releasing excessive amounts of refrigerant into smaller spaces

Regulations and Requirements

Safety procedures for storing and transporting A2L refrigerants are designed to reduce the potential for leaks and accumulation of gases that could pose a fire hazard. For example, tanks containing A2L refrigerants, like R-32 and R-454B, must be stored upright in a secure, ventilated enclosure and cannot be exposed to any elements which may cause them to overheat.

Here are some key safety rules to keep in mind:

- Clearly label containers and storage areas to indicate the presence of flammable materials

- Ensure proper ventilation to prevent accumulation of gases

- Securely fasten cylinders when transporting to prevent movement and potential leaks

- Avoid excessive heat (above 125º F) in vehicles and storage areas

- Equip vehicles and storage areas with compatible fire extinguishers and equipment

- Quantities of 25 lbs. or over are subject to specific storage regulations under Hazardous Material Regulations (HMR)

The Future of R-410A Equipment

Existing HVAC equipment that uses higher GWP refrigerants, such as R-410A, can continue operation for the foreseeable future. However, those higher GWP refrigerants will be phased down over time. This means legacy refrigerants, such as R-410A, will become less widely available and more expensive. Properly reclaiming A1 refrigerants from existing systems is not only beneficial to the environment but will help to manage costs and ensure an adequate supply is available to service the existing R-410A equipment in the market.

Your success is our first priority. From training and FAQs designed to help installers hit the ground running, to resources for building owners and facility managers on the changes that affect them. We’re digging into the details to help everyone understand what to expect and how to stay ahead of the curve.

Lennox® Online Resources

Visit our Low GWP page for online resources to help you manage the transition, including:

- Product Literature

- Installation Guides

- Access To Training Sessions

- Frequently Asked Questions

Sponsored by: