By LARRY FELKER, Belimo Americas, Sparks NV

In cold climates, air-handler water coils must be protected from freezing. On the waterside, this is accomplished with glycol additives, draining of coils as cold weather approaches, the use of run-around pumps, steam preheat in the outdoor-air path, the use of face-and-bypass dampers with constant coil water flow when outdoor temperatures approach freezing, and other measures. This article will discuss protective measures on the airside.

In systems with a single fan, it is standard practice to stop the supply fan and close the outside-air dampers to prevent the entry of below-freezing air. When a return fan exists, the return fan can be operated to help protect the coil. This is also discussed below.

Freezestats

A freezestat is a low-ambient-temperature-limit control device. It is the standard control used to achieve water-coil low-temperature protection. If air temperature at a coil drops to just above freezing, a freezestat changes over its contacts and initiates protective action. It also can be used to open a hot-water control valve to allow full hot-water flow through a coil.

| Check out this additional resource from HPAC Columnist Larry Clark: Choosing the Best Coatings for Heat Transfer Coils |

Freezestat set point typically is 37°F (3°C). Control variations exist. Another automatic-reset low limit may be set at a higher temperature to close the dampers while the fan continues to run. This automatic-reset safety would be set 2°F or 3°F (1°C) higher than the freezestat set point. If the temperature of the mixed air were to rise, the dampers again could go to minimum outside air.

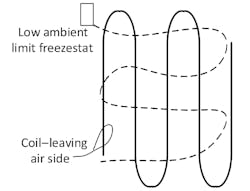

Freezestats have a 10- to 20-ft-long capillary tube that is placed across the face of the leaving-air side of a hot-water coil. The control responds to the lowest 8-in. to 12-in. length of the capillary tube. If any portion sees temperatures dropping to a level at which the coil could be in danger of freezing, its contacts change over. See Figure 1 for a typical capillary tube serpentined on a coil.

The tube is not placed on the entering-air side of the coil because minimum outside air will stratify to the extent that a small portion of the tube can experience below-freezing temperature while the coil itself is in no danger. Nuisance trips of the control can occur.

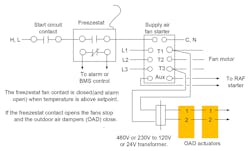

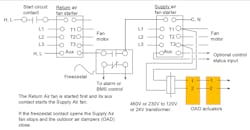

Control can be direct digital or discrete electrical or a mix of the two. Bulb-type sensors are not used be-cause they measure only a small duct area and, given normal stratification, cannot cover an entire coil face. Airflow is complex, and predicting the coldest spot in an air stream is impossible. Contacts can be SPST, SPDT, DPST, or DPDT; both automatic and manual reset controls are available. Many control sequences are possible. See Figure 2 for a typical control wiring method for protecting both single-fan and double-fan systems. A freezestat relay likely would be employed so that the valve can be overridden open, which is not shown.

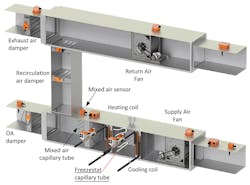

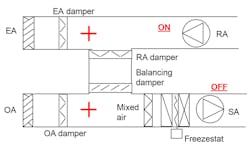

Large systems with both supply-air and return-air fans can be protected in several ways that are superior to the single-fan method. See Figure 3 for a typical large air-handling unit. Note the placement of the freezestat capillary tube.

Figure 4 introduces a concept not in common use. In systems with supply and return fans, the return fan is started first. If the freezestat trips, only the supply fan is stopped (and the outdoor dampers close). This pressurizes the recirculation duct and the outside-air damper from within. As a result, cold outdoor air cannot enter, and the coil no longer is in danger of freezing. Figure 5 shows the pressure concept.

Another variation is, in unoccupied mode, to restart the return-air fan when coil or mixed-air temperature approaches freezing. An automatic reset control can be used. Then, use of the variation in wiring shown in Figure 5 can take final action for valve operation. This adds a layer of protection.

Summary

A number of tactics are used to protect coils from freezing. Among them are runaround pumps, preheat coils, face-and-bypass dampers, and the opening of hot-water valves. Low ambient limits, or freezestats, initiate control actions.

Systems without return fans shut off the supply fan, close the outside-air dampers, and ensure valves are open and pumps operate. If a return fan is present, it can be left on or turned on while the supply fan is shut down and the outside-air dampers are closed. This pressurizes the air-handler exhaust and outdoor dampers, prevents cold air from entering, and warms the coil with inside air. Appropriate valve and/or pump operations also are performed.

###########

The fire-and-smoke-product manager for Belimo Americas, the author is a mechanical engineer who has specialized in actuators and dampers for 25 years. He is co-author of “Dampers and Airflow Control", published by ASHRAE in 2010. He can be contacted at 775-355-2461 or [email protected].