On Nov. 5, Danfoss held its 22nd EnVisioneering Symposium, “Refrigerants2Sustainability,” which focused on complex challenges reshaping the refrigeration landscape, including increased regulatory pressure, increasing energy costs, contractor training on new low-global-warming-potential (GWP) systems that are flammable or mildly flammable, and consumer demands for sustainability.

To explore how these challenges affect the way supermarket and commercial refrigeration equipment is designed, built, and maintained, Danfoss convened approximately 50 thought leaders from industry, policy, utilities, and research. The group heard from experts on the likely evolution of policy, steps companies have taken, demonstration projects that have been conducted, and how industry and utility interests in energy efficiency might align to help finance a transformation.

The State of Refrigerant Policy

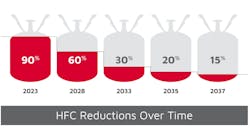

Kevin Fay, executive director of the Alliance for Responsible Atmospheric Policy, opened the symposium by emphasizing the industry’s support of a global phasedown of hydrofluorocarbon (HFC) refrigerants. At an event hosted by the White House in September, the Alliance announced its support for an 80-percent reduction of HFCs by 2050 on a GWP-weighted basis, based on current emissions levels.

Fay informed symposium participants of two new initiatives recently launched by the Alliance in conjunction with industry partners:

- A global refrigerant-management initiative that will help to train and certify service technicians to significantly decrease emissions from refrigeration systems with high energy consumption, as well as from leaked refrigerants.

- A global council that will work to increase the efficiency and lower the GWP of refrigeration equipment to reduce overall food waste, which can equate to as much as 3 billion metric tons of greenhouse-gas emissions globally.

According to Drusilla Hufford, director, stratospheric protection division, U.S. Environmental Protection Agency (EPA), HFC emissions increased by about 8 percent per year from 2004 to 2008, based on information published by the United Nations Environment Programme in 2011. If left unchecked, HFC emissions could rise to nearly 20 percent of the world’s total carbon-dioxide emissions by 2050, a recent publication in the Proceedings of the National Academy of Sciences estimates.

To address this issue, the EPA recently published two proposals under its Significant New Alternatives Policy:

- The addition of new lower-GWP refrigerants, such as propane (R290) and R441A, to the list of acceptable-use refrigerants for certain applications.

- The listing as unacceptable in specific end uses, including commercial refrigeration, certain HFCs, with compliance dates over the next few years.

Hufford provided insight into the refrigerant-management strategy established under Section 608 of the Clean Air Act, which prohibits knowingly venting refrigerants and provides requirements for leak repair and prevention as well as the safe disposal of chlorofluorocarbons and hydrochlorofluorocarbons.

Refrigeration Technologies in the Field

Charles Hon, engineering manager, True Manufacturing, and Tim Anderson, principal engineer, display cases and micro-distributed systems, Hussmann Corp., discussed their companies’ experiences preparing for the path forward.

Hon said implementing hydrocarbons and low-GWP refrigerants is possible, although he noted challenges such as flammability and laboratory testing can be difficult to overcome. He positioned propane (R290)—with an ozone-depletion potential of zero and a GWP of three—as an ideal refrigerant solution, particularly in self-contained refrigeration equipment, citing the system-performance benefits of hydrocarbons, which have been shown to consume 6 to 12 percent less energy than R-134a systems and up to 20 percent less energy than R404A systems with less equipment noise.

Anderson also emphasized the viability of R290 and presented an example of how Hussmann successfully implemented it in micro-distributed systems.

Both Hon and Anderson pointed to the need for qualified technicians who are familiar with the safety precautions and the specialized equipment and components necessary to handle flammable refrigerants.

The Role of Utilities and Incentives

The symposium concluded with discussion of the role utilities could play in developing incentives for new systems that not only cut energy use, but reduce the environmental impact of energy-intense refrigeration processes.

Nick Brod, director of the grocery practice for CLEAResult, noted CLEAResult’s grocery-specific programs, which provide comprehensive energy-efficiency support on behalf of utilities, have saved about 2.6 billion kwh and $286 million in energy costs in more than 10,000 facilities since 2003, and provided more than $68 million in utility incentives.

Joanne Morin, deputy director of the Consortium for Energy Efficiency, reminded participants that demand-side-management programs always are looking for energy-efficient equipment, and refrigerants may contribute to new, higher-performing technologies. She said an expansion of funding for efficiency programs, including commercial-refrigeration savings, may occur in some states as part of the implementation of Section 111(d) of the Clean Air Act, which is meant to lower greenhouse-gas emissions from existing power plants. Complying with the new regulation will cause utilities and their regulators to look at four options: generation efficiency, demand-side efficiency, natural-gas generation, and the use of renewables and nuclear power. Of those, she said, efficiency is the largest, cheapest, and fastest opportunity for emissions reductions.