Despite inroads made by newer approaches to data-center cooling, such as close-coupled systems, in recent years, changes to industry standards, improved components, and the industry adoption of energy-efficient air management have allowed perimeter cooling (commonly referred to as computer-room air conditioners [CRACs] or computer-room air handlers [CRAHs]) to maintain its position as the most widely accepted choice for cooling in mission-critical information-technology (IT) environments. This article examines those developments.

Air Management

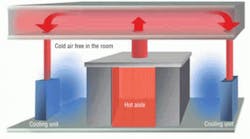

During the 2000s, as data-center heat densities rose at a seemingly exponential rate, the limitations of raised-floor air distribution and the disconnect between heat generation and heat removal became major barriers to IT cooling. This gave rise to new cooling architectures that are closely coupled or “in row” with IT loads for localized heat removal. Preventing hot- and cold-air streams from mixing increased the efficiency, capacity, and predictability of data-center cooling systems and led to the adoption of hot- and cold-aisle containment systems. While these further prevented mixing of hot- and cold-air streams, they also allowed traditional perimeter systems to isolate air streams and act in a closely coupled fashion without requiring air conditioning in close proximity to heat loads.

Similarly, perimeter cooling systems were able to overcome the efficiency gains achieved by the variable airflow of closely coupled cooling systems. The use of supply-side temperature control focused on the IT inlet and fan-speed control employing underfloor pressure sensors used in conjunction with containment strategies leveled the playing field with in-row systems. As an alternative, the deployment of pressure-regulated and fan-assisted floor tiles in perimeter cooling architectures as a means of providing variable air volume to IT equipment has become a pervasive practice in data-center design.

CRAC Components

The CRAC industry mostly has leveraged components from the commercial air-conditioning industry. While designers, manufacturers, and users of CRACs have understood the benefits of energy efficiency for several decades, they have been dependant on the larger commercial air-conditioning market for help driving demand. After a few oil crises and with increased environmental awareness, the commercial market now has substantial motivation for efficiency improvements, which has increased the number of component choices available to CRAC designers:

• Compressors. The CRAC industry long has understood the advantages of matching cooling capacity to thermal load. Initially, this was achieved with semihermetic compressors using a cylinder-unloading technique and multiple refrigeration circuits. This approach typically provided two to six steps of capacity regulation. Any of those steps matching actual load, however, was highly unlikely. Additionally, significant mechanical losses were associated with the unloaded cylinder(s).

Today, we see compressor-modulation schemes offering significant capacity turndown and almost step-free proportionality from minimum to maximum capacity. Particularly favorable is the use of variable-speed compressors. Frequently, a variable-speed compressor is combined with a constant-speed compressor on a single refrigeration circuit. This method provides high efficiency with large proportional turndown, along with lower first cost. Other choices may include pulse-width modulation of compressor pumping. This is intermittent interruption of pumping while a compressor runs continuously, which offers exceptional turndown. Regardless of the modulation technique, more closely matching cooling capacity to cooling load provides substantial efficiency gains.

• Fans. Legacy CRAC units typically used a forward-curved centrifugal fan in combination with a motor couple by belt with variable-pitch pulley. The adjustment of the variable-pitch pulley provided a limited adjustment of final fan-drive speed. This adjustment traditionally was limited to initial startup (compensating for different static pressure). Forward-curved fans were highly sensitive to reduced performance based on discharge considerations and offered modest static efficiency.

Today, we see the use of electronically commutated fans. These fans offer the ability to adjust speed in real time based on control algorithms that monitor the airflow demands of a data center. The use of backward-inclined, as opposed to forward-curved, fans has provided higher static efficiency and reduced sensitivity of fan-discharge configurations.

• Expansion valves. The combination of variable-speed fans and modulating compressors can make accurate regulation of refrigerant flow into a cooling coil difficult. Expansion-valve rangeability will be inadequate when legacy mechanical valves are used with variable-capacity compressors and fans.

Electronically controlled expansion valves can accurately regulate the flow of refrigerant into a cooling coil over the wider operating conditions introduced by airflow and compressor modulation. This wider rangeability is particularly important, as incorrect metering of refrigerant into a cooling coil can greatly reduce system efficiency and compressor reliability.

CRAC-Industry Standards

Until 2010, data centers were exempt from the requirements of ANSI/ASHRAE/IESNA Standard 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings. A common theme of the 2010 version of the standard is the need for economizer-based cooling in new data centers. Exemptions are limited, depending on ASHRAE climate zone and the base load of a data center.

Recently, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) announced an organizational meeting for a new section that would include data-center cooling products. This may open the door for third-party certification of cooling-product performance. AHRI presumably will leverage ANSI/ASHRAE Standard 127-2007, Method of Testing for Rating Computer and Data Processing Room Unitary Air Conditioners, which is being revised to include more appropriate rating conditions, based on actual return-air temperatures achieved with contemporary best practices.

Economizers

As local code agencies adopt newer standards and states pass their own requirements, the demand for economizers and the ability to leverage resulting efficiency gains increase. For many new buildings, data centers can be designed around an architecture that can leverage air-side economization. Applications such as high-rises and data-center retrofits, however, must leverage a water-side system to take advantage of economizer operation.

Water-side economizer configurations have been available for perimeter cooling systems for many years. This approach uses the heat-of-rejection water loop as a cooling fluid when the outdoor temperature is cool enough. The system diverts the cold fluid away from the condenser to a secondary free-cooling coil. Most systems have the ability to operate in partial economization with the vapor-compression system operating at part load.

A considerable number of data centers are taking advantage of perimeter units as the filtration, humidification, and control function of an air-side economizer system. Placed on an outside wall and fitted with a hot-air return duct connected to outside air, a unit can serve as a control source utilizing outside air and mechanical cooling during economizer operation. When outside air is cold enough to provide all or a portion of the cooling capacity, the unit reduces or shuts off the vapor-compression cycle to save energy and opens a damper to leverage outdoor ambient temperature. Routing this cold air through a perimeter system keeps the air entering a data center filtered and controls air moisture during economizer operation.

Perimeter-cooling economizer modes once were limited to the air-side approach described above or a water-side system utilizing a secondary coil and heat exchange with existing heat-rejection fluid. As a result, air-cooled systems did not have an economizer option. Recently, that changed, with a newer option in air-cooled systems using a secondary coil to route refrigerant to a thermal siphon circuit and a refrigerant pump to circulate the refrigerant. When outdoor temperature allows, the unit turns off the vapor-compression cycle, and the pump takes over refrigerant circulation. The use of a refrigerant pump, as opposed to a compressor, in this mode reduces energy consumption while providing the necessary cooling. This configuration expands economizer options and extends the ability of perimeter cooling to meet the needs of customers and engineers designing around new industry standards.

Summary

Just a few years ago, it appeared perimeter cooling was giving way to new data-center cooling architectures and the result would be a decline in market share. Changes in industry standards, new air-distribution methods, advances in components, and increasing economizer demands have changed what once seemed to be an inevitable fate. While most industry reporting agencies agree that row and rack cooling and air-side economizers will experience higher market-share growth rates over the next several years, perimeter cooling represents by far the largest share by cooling type and is expected to be flat or slightly up over the same period. With perimeter cooling’s considerably greater share, it will be many years before other cooling architectures catch up.

As product manager, cooling, for Schneider Electric, Kevin Dunlap is responsible for the engineering and marketing of cooling solutions. He has been involved in the power-management industry since 1994 and worked for Schneider Electric and Schneider Electric subsidiary American Power Conversion (APC) since 1997. He has participated in numerous power-management and cooling panels, as well as industry consortia and ASHRAE committees on thermal management and energy-efficient economizers. The director of innovation and technology, racks-cooling solutions, for Schneider Electric, John Bean Jr. has more than 30 years of experience in the design, support, and manufacture of mission-critical thermal solutions. Previously, he served as director of research and development, cooling solutions, for APC, developing several new product platforms and establishing engineering and laboratory facilities in the United States and Europe. He is an active member of The Green Grid, which he serves as vice chair of the Technology and Strategy Workgroup, and ASHRAE, which he serves by working primarily on Technical Committee 9.9, Mission Critical Facilities, Technology Spaces and Electronic Equipment.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].