Portable Cooling: Equipment and Applications

It's summer, a time when overworked HVAC systems become prone to failure and portable air conditioners are pressed into emergency service. But portable air conditioners are not just for use in hot weather. They can provide solutions to a range of heat-related and comfort challenges year-round. This article will review what facility owners and managers need to know about portable cooling equipment for the summer season and beyond.

Equipment Types

There are three main types of portable equipment in use today:

- Air-cooled portable air conditioners, which exhaust hot air through ductwork. Air-cooled portable air conditioners are the most commonly used equipment because they can be installed almost anywhere, usually in minutes. They are preferred over water-cooled units where water leakage, no matter how unlikely, would be catastrophic (e.g., in rooms that house computer servers).

- Water-cooled portable air conditioners, which connect to an external water source. They are best-suited for use in facilities with central cooling towers or chiller systems or where the municipal water supply is plentiful and economical. Water-cooled systems do not require exhaust ducts, so they often are specified when there is no convenient way to exhaust hot air out of a room (e.g., in restaurants).

- Evaporative coolers, which use an internal or external water source to provide cooling and a fan to push air across a space. Although their performance is not comparable to that of portable air conditioners, they can provide a simple, low-cost cooling option for specialized use—most commonly, for outdoor areas where the budget or power supply is limited, as they can run on standard residential current. Warehouses are another common application for these units.

The Role of an Emergency Preparedness Plan

When it comes to protecting people, equipment, and/or critical processes, it is wise to plan ahead and be prepared for the worst-case scenario. If you anticipate using portable cooling for emergency backup:

- Make sure there is a backup generator capable of providing sufficient power for portable cooling.

- Pinpoint areas to be cooled.

- Consider special vulnerabilities. Power outages are not the only factor to consider. Rooftop air handlers and other outdoor units may be vulnerable to breakdowns caused by fallen trees and airborne debris.

- Check nearby power outlets for the required voltage and phase. If none is available, determine the requirements for electrical cables, extension cords, and other accessories.

- Establish a written emergency cooling plan that includes a list of the areas to be cooled, a full inventory of needed portable units and accessories, and emergency contact information for the portable-air-conditioning supplier.

- When possible, specify equipment delivery before an anticipated event, such as a hurricane. When disaster strikes and panic mode sets in, the demand for portable cooling equipment often exceeds the local supply. Ordering ahead is the best way to ensure your facility will have the right equipment at the right time.

Portable Cooling Solutions for Non-Emergencies

Besides emergency backup, a common application for portable air-conditioning units is bridging gaps during construction or renovation. When work on a building addition or remodel is under way, a central HVAC system may be shut down or not even be installed yet. Not only does portable cooling provide relief to construction crews, it can facilitate work processes. For example, by controlling temperature and humidity, it allows faster drying of spackle and better acclimation of wood flooring and paneling to prevent warping or buckling.

Page 2 of 2

Similarly, if an HVAC system is shut down for refurbishing or replacement, portable units can be brought in to deliver cooling for as long as needed, ensuring comfort of building occupants and protection of heat-sensitive equipment until the permanent system is up and running.

Special events also can benefit from portable cooling. Tented weddings and parties require more cooling capacity than typical building applications because of the heat loads generated by large crowds. A good rule of thumb is 1 ton of portable cooling for every 125 to 175 sq ft of tented area. For outdoor events in open areas, evaporative cooling is an option worth considering. "Evap" or "swamp" coolers are used most frequently in desert climates, but even in Florida, evaporative cooling can yield a 5°F to 15°F temperature reduction.

Portable equipment often is installed on a permanent basis to cool special areas with heavy heat loads, such as computer server rooms, or to deliver supplemental cooling when a primary HVAC system no longer is adequate. Portable units also can provide targeted cooling in server rooms, office suites, and other areas during nighttime and weekend setback of building thermostats, saving energy by delivering cooling only when and where it is needed.

Portable units offer great flexibility for tenants who rent space, who move or renovate frequently, or whose leases prohibit the installation of permanent equipment. Because portable units can be rented, capital expenditures are avoided.

Equipment-selection factors

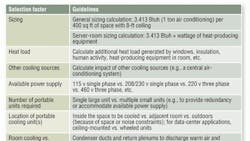

There are many things to consider when selecting portable cooling equipment. Table 1 lists selection factors to review with suppliers.

Proper selection starts with equipment sizing, defined as cooling capacity in British thermal units per hour or tonnage (12,000 Btu = 1 ton of cooling). Basic mathematical formulas may be used to size portable coolers for general applications and for server rooms, but heat-load factors unique to the application must be taken into account. Also, every portable air conditioner is designed for use with a particular type of electric circuitry, so the available power supply will impact final equipment selection.

Will the unit be located inside or outside of the space to be cooled? If the unit will be located inside, the first decision is whether to use one or two ducts. For some applications, it is advantageous to use a single duct coming off the top of the unit to vent warm air into the return-air plenum or out of the space. This approach often is used in facilities in which a central air-conditioning system is running at all times. As warm air is directed out of the room, new air needs to be brought in. Air from surrounding areas will be drawn in because the unit is creating a negative pressure.

What if the building uses night/weekend temperature setback? In such a situation, it is best to put a condenser plenum and additional duct on the unit so there are two ducts going to the drop ceiling. This makes a closed-loop system that no longer creates a negative pressure. With the door shut, the space can be cooled independently. The system will pay for itself quickly through energy-cost savings.

If a unit must be located outside of the space to be cooled, find a way to get the return- and cold-air supply inside. This might involve cutting openings in drywall to insert ductwork. If the portable installation is temporary, alternative solutions (e.g., going through windows or other existing openings) can be found.

Another consideration is how to dispose of the condensate water created by the cooling process. This can be done by using a standard condensate tank or bucket that comes with a portable cooler or by running a condensate line from the unit and pumping the water to an external drain. The latter approach often is used in server rooms.

Selecting a Supplier

When selecting a portable-cooling-equipment supplier, ask:

- What kinds of equipment the supplier offers. Look for a supplier that carries equipment from multiple manufacturing sources so you can get unbiased advice on the best unit for your application. Insist on equipment designed and manufactured to be portable, not permanent systems with wheels added. Ask what accessories are available and whether they are included in the basic rental price.

- If the supplier has a national accounts program. If you own or manage multiple facilities, you may be able to save time and money with an integrated program that includes a single point of contact for all of your service needs, a customized emergency-response plan, and the ability to accommodate your company’s ordering system.

- What kind of technical support is available. If you manage government facilities, determine if the distributor is U.S. General Services Administration-certified. Ask if the supplier follows green initiatives, such as the use of environmentally friendly refrigerants.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].