RAYS OF HOPE: Germicidal UV Can Limit Spread of Contagious Diseases

By DANIEL JONES, UV Resources, Santa Clarita CA

As workplaces gear up to welcome employees back and businesses prepare to reopen buildings closed during the COVID-19 pandemic, companies are looking to building engineers and facility managers to provide guidance on how to protect occupants now and during future epidemics.

Ultraviolet Germicidal Irradiation (UVGI or UV-C) is drawing widespread attention as a formidable weapon against surface and airborne bacteria and pathogens. Decades of research and thousands of applications in hospital ER and operating rooms, urgent care centers, universities and first-responder locations have demonstrated germicidal UV-C’s ability to inactivate viruses, mycoplasma, bacteria and fungi. That said, UV-C technology has long been misunderstood and therefore under-utilized in the HVAC sector.

What the COVID-19 virus has triggered is an unprecedented level of attention to infection control and a corresponding realization that communicable diseases can devastate global economies. Overnight, germicidal UV-C technology has transformed from an HVAC energy savings accessory to a means to help fight a pandemic, as well as regain employee and customer confidence.

Now, as facility managers look to plot their path forward, they would be well advised to seek a multi-layered approach that incorporates several infection-control measures such as germicidal UV-C to help ensure that whatever pathogen cannot be removed by one method (say, filtering or cleaning) is inactivated by another (UV-C).

Killing Airborne Pathogens

Certainly, using the germicidal UV-C waveform (253.7 nm) for disinfection is not a new application. In 1877, researchers in the journal Nature described how sunlight prohibited the growth of microorganisms. Since the 1940s, many hospitals have relied upon germicidal UV-C energy to control airborne infectious diseases, but use waned with the arrival and proliferation of antibiotics. However, in the 1990s, drug-resistant “superbugs” and hospital-acquired infections sparked a renewed interest in UV-C, which can kill virtually any microorganism, including antibiotic-resistant germs.

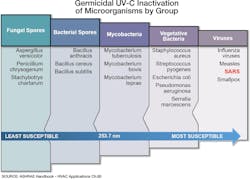

Although bacteria and viruses absorb UV-C energy at different rates, all microorganisms tested to date respond to UV disinfection at the appropriate doses.1 ASHRAE, too, has recognized that the UV-C wavelength inactivates virtually all microorganisms living on HVAC/R surfaces with a kill ratio of 90% or higher, depending on UV-C intensity and length of exposure.2

UV light comprises a segment of the electromagnetic spectrum between 100 and 400 nm, corresponding to photon energies from 3 to 124 eV. The UV segment has four wavelengths, labeled: UV-A (400 to 315 nm); UV-B (315 to 280 nm); very high energy and destructive UV-C (280 to 200 nm); and vacuum UV (200 to 100 nm).

UV-C’s germicidal or germ-killing effects are well proven. The 253.7 nm electromagnetic waveform is well absorbed by DNA and RNA (the genetic code for all lifeforms), changing its structure. This damage inhibits the ability of the affected cells to reproduce, meaning that they cannot infect and are no longer dangerous. Therefore, viruses and bacteria cannot develop a resistance to germicidal UV because it kills energetically, rather than biologically.

Three Methods of Applying UV-C Energy

There are three primary means of applying UV-C for air and HVAC surface protection against infectious agents: 1) Upper-Room or Upper-Air; 2) HVAC airstream disinfection; and 3) HVAC coil/surface irradiation:

1. Upper-Room/Air systems work by interrupting the transmission of airborne infectious diseases in high traffic communal areas. Immunocompromised and contagious individuals in Emergency Room waiting areas, urgent care facilities, doctor offices or senior living centers increase the potential for community spread by positioning potentially undiagnosed/untreated patients near others. The Upper-Room UV-C fixtures utilize the natural rise-and-fall of convection or mechanical air currents to lift contaminated air into a UV-C disinfection zone where infectious agents are inactivated.

Operating 24/7/365, Upper-Room germicidal fixtures can inactivate microbes in under a second, including measles, mumps, TB, and cold viruses. These fixtures are wall-mounted above seven-feet and use baffles to direct the UV-C energy upward and outward ensuring that UV-C energy does not enter the occupied portion of the room. Kill ratios of up to 99.9% on a first-pass basis have been modeled and concentrations are further reduced by each subsequent pass of recirculated air (“multiple dosing”). The goal, relative to coverage, is to maintain average UV-C irradiance levels in the upper room at a minimum of 30-50 microwatts per square centimeter (µW/cm2).3

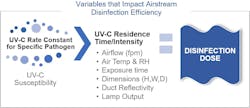

2. HVAC air-stream-disinfection systems. UV-C air disinfection systems are installed in-duct, in air-handling units or air distribution systems to inactivate microorganisms and disinfect moving airstreams “on-the-fly.” UV-C exposure and the resulting dosage is determined by the amount of germicidal energy absorbed by a pathogen over a specific period of time. While that may sound easy, there are many operational conditions that will directly impact airstream disinfection rates:

• Target Pathogen and its susceptibility to UV-C. The UV-C dose/fluence required to inactivate specific RNA and DNA viruses have been identified in various scholarly research,4 dating back multiple decades to the present. These studies provide the necessary information/pathogen susceptibility that is used with predictive-modeling to estimate how much UV-C is necessary to kill individual bacteria, viruses or spores;

• Time/Intensity. The volume and velocity of air traveling through an HVAC system significantly impact the length of exposure to the germicidal wavelength (residence time)—a higher volume of air and/or faster-moving airstreams require greater intensity (more UV-C lamps);

• Air Temperature. Warmer air is more conducive for UV-C lamp performance, enabling increased UV-C output as compared to colder supply air leaving a coil;

• Lamp Location and Output. Because cold air reduces the output of UV-C lamps and high RH affects pathogen susceptibility to UV-C, on-the-fly airstream disinfection applications are more efficient when installed on the upstream side of the coil. In fact, moving UV-C lamps from 55-degree temperatures (typical of downstream) to 75-degree (typical of upstream) can increase a UV-C lamp’s output by 40% or more. On-the-fly disinfection can be accomplished downstream of the coils; however, this would require an increase in UV-C intensity (i.e. more lamps).

Most lamp manufacturers (Phillips, GE, and Sylvania, etc.) recommend removing and replacing UV lamps every 9,000 hours (roughly once a year). Most quality lamps will emit < 85% of their original UV-C output at the end of one year.

Separately, UV-C lamps that are encapsulated with an FEP coating or outer sleeve help to insulate the lamp surface from air volume and temperature changes. This can provide for an increase in lamp output and performance in extreme operating conditions of low temperatures, and in high-velocity air streams;

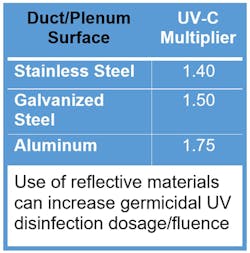

• Reflectivity. UV-C energy’s effectiveness is multiplied (see chart) as it bounces off of the top, bottom, and sides of a plenum surface. Certain surfaces like aluminum can allow more UV-C energy to reflect and “stay in-play”, versus being absorbed by the surface. Most cooling coil fins are made from aluminum, which also assists with UV-Cs penetration into the coil and overall reflectivity.

Each of these factors will determine the amount of UV-C energy necessary in any given application (installations are typically modeled to help predict individual dosage levels).

For example, to keep cooling coils free from mold and bacteria, lamps might be installed on the downstream side of a coil surface, spaced every 30-40 inches of coil height, this equates to roughly 7.5 lamp watts per square foot,5 i.e enough UV-C energy to get the job done. In this example, because the target (coil) is stationary, the exposure time to UV-C is 24/7/365, so the UV-C intensity can be lower.

However, for a moving airstream, UV-C intensity must be increased due to the limited residence time that the target pathogen(s) will be exposed to the UV-C energy. Greater UV-C dosage can be achieved by using high output lamps—which will increase the total microwatts per square centimeter (µW/cm²). Additionally, increasing UV-C fluence can be achieved by adding more lamps, thus decreasing lamp-row-spacing, from the surface irradiation standard of 36-inch centerlines to 14-inches or less.

Predictive-modeling based on scientific studies of each pathogen’s susceptibility to UV-C can assist in designing the recommended dosage rates required to kill individual bacteria, viruses, or spores. Studies have demonstrated that viruses (e.g., influenza, measles, SARS and smallpox) are more susceptible to UV-C inactivation than, say, bacteria (see chart);

3. Coil-irradiation systems are installed within HVAC air-handling units and duct runs. As air-conditioning equipment ages, its ability to maintain designed air temperatures and humidity levels decline. Predominantly, the culprit is reduced coil-heat-transfer efficiency, or the ability of the AHU’s cooling coil to remove heat and water from the air. Evidence shows this drop in performance can occur within five years of startup due to the buildup of biofilm on coil surfaces. Of course, there are energy and other cost penalties associated with coil fouling, such as fans and chilled water systems consuming more energy to compensate for lost coil capacity.

A system installed for coil irradiation can also have a secondary benefit of eliminating up to 30% of airborne pathogens on a first-pass basis (and these concentrations are further reduced by each subsequent pass or “multiple dosing”).

ASHRAE’s Applications Handbook also suggests that the UV-C irradiance levels should strike coil surfaces at a minimum of 50-100 µW/cm2. As noted above, a more understandable and convenient way to achieve the recommended dosage of UV is to use lamp watts, which is printed directly on the lamps made by all major brands. ASHRAE’s recommendation of 100 µW/cm2 works out to be slightly under 7.5 lamp watts per square foot of the coil surface area.

How HVAC Engineers Can Help

While the use of UV-C to irradiate cooling coils is more commonplace, in the current pandemic, facility engineers and owners are learning that germicidal UV is an established means of killing airborne pathogens and mitigating the spread of infectious https://www.ashrae.org/file%20library/about/position%20documents/pd_infectiousaerosols_2020.pdfdiseases in ventilation systems, as well as in occupied spaces.

Although scientists are learning more about the COVID-19 virus every day, authorities currently believe that coronaviruses can be transmitted via both air and direct contact. Researchers have found that human coronaviruses, such as COVID-19 and SARS, can remain viable up to nine days on surfaces such as metal, glass or plastic.6 Therefore, it is incumbent on facility engineers to use preventative infection-control measures such as UV-C to mitigate the potential spread of airborne diseases.

Conclusion

Although germicidal UV-C systems have been used for more than 80 years, their application in infection control settings has waxed and waned. Given today’s growing desire to prevent the transmission of infectious diseases, facility professionals can utilize germicidal ultraviolet technologies to greatly reduce concentrations of pathogens in a highly reliable and cost-effective fashion.

The ASHRAE Applications Handbook states that the UV-C wavelength can kill 90% or more of all microorganisms living on HVAC air ducts and evaporator coils, depending on UV-C intensity, length of exposure (residence time), UV lamp placement and lamp life cycle. Operating 24/7/365, Upper-Room germicidal fixtures can inactivate microbes in under a second including measles, mumps, TB and cold viruses. In fact, ASHRAE’s position document on airborne infectious diseases (that was just reaffirmed in February 2020) identifies proven methods of controlling airborne infections, including ventilation, particle filtration and germicidal UV-C energy.

Germicidal UV has been extensively peer-reviewed and is recognized in two ASHRAE Handbook Chapters (2019 HVAC Applications and 2017 Fundamentals (Ch. 62), two ASHRAE test standards (ANSI/ ASHRAE 185.1 “Method of Testing UV-C Lights for Use in Air-Handling Units or Air Ducts to Inactivate Airborne Microorganisms” and 185.2 “Method of Testing Ultraviolet Lamps for Use in HVAC&R Units or Air Ducts to Inactivate Microorganisms on Irradiated Surfaces,”) as well as three ASHRAE Position Documents (Airborne Infectious Diseases; Infectious Aerosols; Filtration and Air Cleaning).

Additionally, the Centers for Disease Control (CDC) has recognized the benefits of UVGI to mitigate the spread of infection in its Guidelines for Environmental Infection Control in Health-Care Facilities; Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings; and COVID-19 Employer Information for Office Buildings.

Recent guidance from ASHRAE, the CDC, and published technical articles in HVAC trade publications provide healthcare engineers and facility staff with the resources needed to size, select, install, operate and maintain UV-C systems.

###########

The author, Dan Jones, is president and co-founder of UV Resources, which he started in 2005. He serves on both ASHRAE Technical Committee 2.9 and ASHRAE SPC-185.2, devoted to Ultraviolet Air and Surface Treatment. Contact him at [email protected].

References

1. www.iuva.org/COVID-19;

2. (ASHRAE 2015). ASHRAE Filtration and Air Cleaning Position Document Committee. 2015. ASHRAE Position Document on Filtration and Air Cleaning.” ASHRAE: 10. Web.

3. Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings, U.S. DEPARTMENT OF HEALTH AND HUMAN SERVICES. www.cdc.gov/niosh/docs/2009-105/pdfs/2009-105.pdf?id=10.26616/NIOSHPUB2009105;

4. Kowalski, Wladyslaw & Bahnfleth, William & Hernandez, Mark. (2009). A Genomic Model for Predicting the Ultraviolet Susceptibility of Viruses and Bacteria. www.iuvanews.com/stories/pdf/archives/110201KowalskiEtAl_Article.pdf;

5. Fencl, F., Rightsizing UV-C Lamps for HVAC Applications, 2013, HPAC Engineering. www.hpac.com/air-conditioning/article/20927323/rightsizing-uvc-lamps-for-hvac-applications;

6. Kampf, G., Todt, D., Pfaender, S. & Steinmann, E., Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents, 2020, Journal of Hospital Infection.

###########