Lunching and Learning: Food for Thought on a Geothermal-Heat-Pump-System Design

Editor’s note: In August 2015, HPAC Engineering published “Lunching and Learning: A Civil Engineer’s View of a Campus Chilled-Water System” by Jeffrey Newcomb, an article written entirely as a conversation between two engineers—the fictional Fred and William—having lunch. In the article, Fred, a mechanical engineer, explains his unusual design for a campus chilled-water system to William, a civil engineer. William asks questions and makes observations, system diagrams scribbled on napkins are exchanged, and Fred is left with a new way of thinking about his design. Sound familiar? “Over my 40-plus years as a consulting engineer, I have literally had hundreds of such lunch meetings,” a member of HPAC Engineering’s editorial advisory board who reviewed the article said. “… It’s just what engineers do.” The format of the article was a clever attempt to start a conversation, to introduce a concept—one not quite fully developed—and inspire others to, in Jeffrey’s words, share “ideas that just might need to have a little more exposure to really drive more imagination and innovation in our field.” Indeed, as if sitting at the next table, overhearing Fred and William’s conversation, our editorial advisor said: “The first time I went through (the article), I found myself saying, ‘No, there’s a better way to do that,’ and got a piece of paper to start sketching. It could have been a placemat, but I was in my office.” With that, we invite you to pull up a seat for Fred and William’s latest lunch meeting.

Fred, a mechanical engineer, and William, a civil engineer, had been friends for years and met weekly for lunch at their favorite restaurant. William enjoyed hearing about Fred’s unusual HVAC solutions, while Fred appreciated the fresh perspective William seemingly never failed to provide. On this day, the waitress had barely finished taking their orders when Fred, champing at the bit, asked William, “Are you familiar with geothermal heat-pump systems?”

“Oh, yes,” William replied. “We have seen them taking up a lot of space on site plans for well fields on our projects.”

“Well, I have a twist related to those well fields that I am looking at for a new project,” Fred said. “Actually, it all started as a result of a fishing trip.”

A week earlier, Fred, along with Gordon, a professor at a nearby college, had been invited by Marta, a power-plant engineer, to fish on Gibson Lake.1 The lake was beautiful, but a little odd: It was built above the surrounding ground, not in a valley. Also, there was a spine of land that went almost all of the way across the lake that Fred had noticed on a map. After they cast their fishing lines, Fred asked Marta about it.

“This lake is one big cooling pond,” Marta explained. “A power plant is located at the north end, near the base of the spine. Hot water is discharged on one side of the spine. By the time it goes around the far end of the lake and back, it has cooled off enough to cool the plant again.”

“Wow,” Fred replied. “A whole power plant’s cooling load.” Just then, Fred felt a tug on his line. The large fish at the other end spit the hook, leapt out of the water, and seemed to laugh at Fred before swimming away. Then, it was back to waiting for a bite.

After a while, Marta said, “If you’re getting too hot, we can move to the cooler part of the lake.”

“Cooler?” Fred asked.

“You know, farther from the outflow from the power plant,” Marta said.

That got Fred thinking. “So, the temperature varies with the location relative to the outflow?” he asked.

“Yes,” Marta replied. “The heat input of the plant affects the temperature of the lake. It is like a gigantic lazy cooling tower. Heat flows into the lake from the power plant and out into the air by evaporation of water from the lake and into the ground by conduction. The water close to the power plant is warmer because the water is losing heat as it travels around the lake. Because of the heat input and the stored heat, the lake never freezes. In fact, it normally does not get below 40°F all year.”

Fishing gives one plenty of time to think and the mind ample opportunity to wander, especially on a day like today, when the fish seem to be in no hurry to take the bait. Fred was a typical engineer, always wondering about the world around him. He imagined the flow of heat in the lake. Heat from the power plant charged the lake and was discharged into the air and ground. The heat going into the ground could short-circuit the intended flow of heat around the lake and allow heat from the warmer water to flow into the cooler water near the intake to the plant.

Fred’s bobber had been dancing for a while now—a small bluegill had taken the bait and was putting up a valiant fight—but Fred had not noticed.

“Are you thinking about work again?” Marta asked.

“What? Oh,” Fred said, pulling in his line. He unhooked the bluegill and returned it to the lake.

“Typical engineer,” Gordon said with a laugh. “No ‘off’ button when it comes to work.”

Fred smiled and shrugged. “Marta, when they built this lake, did they put insulation on the bottom to keep heat from the hot side from transmitting over to the cold side?” he asked.

“No, they did not,” Marta replied. “That heat flow was so small compared to the evaporation of the water, it was not needed, and it would have cost a lot to put it in. They did take great pains to make sure there would be no direct water flow from the hot side to the cold side; a water leak can carry a lot of heat.”

Hot side.

Cold side.

They continued to fish, but Fred’s mind was elsewhere.

Fred knew Gordon taught a class on solar engineering and, so, asked, “Isn’t there some kind of a wall that stores solar heat for use later?”

“That is a Trombe wall,” Gordon replied. “Those are thick masonry walls that warm up in direct sunlight during the day and then discharge the heat out the other side at night. The heat flows through slowly in waves.”

Now, it was Gordon’s turn to get a hit on his line. Gordon managed to land a pretty-good-sized catfish. The fish seemed annoyed as Gordon carefully removed the hook from its mouth and returned the fish to the water.

Fred asked, “If the Trombe walls were thick enough, could you have a heat wave from the summer flow out the other end in the winter?”

“Sure,” Gordon replied. “It happens all the time—in caves. To have your heat wave last through a season, your walls would have to be very, very thick. The only place you could build such a place would be underground.”

Fred had another question: “Can the heat waves reverse direction?”

“Yes,” Gordon answered. “As always, heat flows from higher temperature to lower temperature. It happens in a Trombe wall, too. Heat in a Trombe wall starts flowing backward as soon as sunlight no longer is hitting the wall. But, by then, heat has moved so far into the wall more of it comes out the far end because the warm section of the wall is closer to that end.”

Fred had been working on a ground-source-heat-pump design for a school building and wondering if there is a more efficient way to move heat into and out of the ground.

To Fred, the ground seemed like a big thermal battery that is charged with and discharges heat.

Unlike a power plant, a ground-source-heat-pump system sometimes rejects heat to the ground and sometimes pulls heat from the ground. During winter, you want to pull heat from the ground, and during summer, you want to reverse the flow of heat. If you are reversing the flow of heat, why not reverse the flow of water, too?

In a linear system such as horizontal bores, there could be a hot end and a cold end, just like the lake has a hot side and a cold side. Flow could be reversed depending on whether the system was heating or cooling overall. When the system was cooling, hot water would flow into the hot side of the geothermal field, give up heat, flow to the cold side, cool, and then return to the building. The cooler the water, the higher the efficiency of the heat pumps in the building.

When the system was heating, the flow would be reversed. Cold water from the building would go to the cold side of the geothermal field; warm a bit, but still cool the cold side; flow to the hot side; warm even more; and then return to the building.

Over time, the hot side and the cold side would tend to get hotter and colder, respectively. How much hotter and colder was difficult to say without an operating system and records showing how the building was used. Affecting the temperature difference between the hot and cold sides would be the amount of heat pushed into the ground during summer compared with the amount of heat taken out of the ground during winter. For now, Fred could design a normal well field, with the added capacity being a bonus for the owner.

Fred went home still thinking about his ground-source-heat-pump system.

On Monday, Fred called Sam, a ground-source-heat-pump well driller.

“Sam, have you ever done a horizontal borefield with headers at each end just set up as a once-through system?” Fred asked.

“Nope,” Sam answered. “That would mean running a big pipe all the way back from the far end. That would get expensive. We have done a ‘U’ shape before; we had to turn the top of the ‘U’ out to get the pipes the same length. Would that do for you?”

“Maybe,” Fred said, pulling out his plans and his calculator.

Later, Fred dropped his mechanical pencil in disgust. There just was not enough room on site for a “U” loop big enough to handle the building load—even using three levels of loop. A horizontal well field just did not have the capacity needed. The ground-source-heat-pump system would have to use vertical wells.

Fred went outside for a walk.

Hot side.

Cold side.

Could he do hot and cold sides using vertical wells? Normally, vertical wells are piped in parallel. With large systems, there might be several circuits going back to a header in a vault, but they are piped in parallel to reduce pressure drop. Having hot and cold sides with vertical wells would require groups of wells to be piped in series. Larger piping might be needed for the wells to avoid a very large pressure drop. It could work. Reversing flow to the field would be tricky, but not impossible.

The next day, Fred would be meeting William for lunch. There would be plenty to talk about.

Fred took a bite of his fish sandwich (delicious, even if he did not catch it himself) and began recounting the experiences of the past week to William.

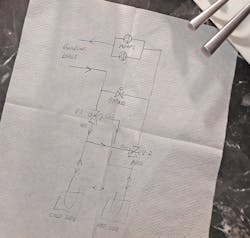

“The ground-source well fields are all using the earth as a battery, storing heat from the summer to use next winter,” Fred said, sketching his plan on a napkin (Figure 1). “It all starts with a well field that is like two well fields tied together. Hot water in the summer goes into the hot wells first and then into the cold wells. That should give a larger delta-T than you normally get from a ground-source well field and increase the operating efficiency of the heat pumps.”

“Interesting,” William said. “I don’t believe I have heard of it being done that way before.” He had been enjoying his sandwich while Fred’s received scant attention. That happened a lot.

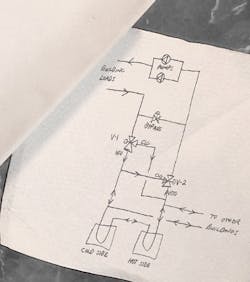

William continued: “I don’t believe I’ve heard of flow being reversed in geo well fields before, either. How do you decide when to reverse the flow, and how do you accomplish that?”

“The flow reverses based on temperature,” Fred answered. “If the water coming from the building is 3 degrees warmer than the water from the hot side of the well field returning to the building, we reverse the flow. When water is flowing the other direction and the water from the building is 3 degrees colder than what is coming back from the cold side, we reverse the flow again.”

Fred took a hasty bite of his sandwich before continuing: “The valving gets a bit tricky. Here is how that will work (Figure 2).

“There are several other buildings around—owned by the same school district—that have slightly different needs for heating and cooling,” Fred continued. “In a future project, the nearby high school will be converted to ground-source heat pumps. If all the buildings have a similar valving setup, heat can be shared between buildings without ever going to the well fields. There will be times of the year when this smaller building with large outside-air loads will need heating the same time the high school needs cooling. This hot-side/cold-side design will allow those buildings to share heating and cooling water. Crossing those flows will make the heat-pump inlet water temperatures for both buildings better than would normally be obtained from a ground-source well field.”

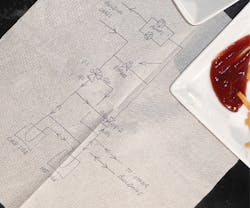

Fred updated his sketch (Figure 3). “We will leave connections for the high school here,” he said.

William sat quietly, thinking, while Fred finished his sandwich.

“You have main pumps that circulate water through the building and out to the well fields,” William said. “I am guessing one of those pumps needs to run all the time. I know you will have them on VFDs and reduce the flow when the loads are low, but you will always need some minimum flow. That minimum flow might ‘wash out’ the temperature differential between your fields. How will you deal with that problem?”

“Hmmm,” Fred said. “I had not thought of that. Do you have time for dessert today? I have something in mind, but need to think about it a bit.”

After a slice of pecan pie (warmed, with ice cream), Fred was ready to discuss his idea.

“The problem is that I really do not want to send water through the well fields when there is not enough load,” Fred said. “I have a bypass so that the whole system does not need to shut down when the flow reverses, so now I just need to figure out when and how to operate the bypass (Figure 4). I am thinking the bypass should modulate to maintain a 65°F supply-water temperature to the building. Water will be mixed in from either the hot side or the cold side to maintain that temperature as long as it can. During heavier loads, the temperature will still vary, but that gets the load to the field. That maximizes the delta-T of the well field and prevents the ‘washout’ you mentioned. As a benefit, we will save a lot of pump energy most of the year, when the system is operating in that mode.”

William smiled. “That sounds like a good solution to me,” he said. “See you next week.”

What do you think of Fred’s design? Could this hot-side/cold-side scheme be used in other systems? Is 65°F the right temperature to use for control of the bypass? Have you ever had a geothermal system “wash out” as William described? What other unusual systems should Fred consider? Please comment below, or send your thoughts and ideas to Executive Editor Scott Arnold at [email protected].

Note

- Gibson Lake is a real place in Southwestern Indiana. Unfortunately, fishing no longer is allowed there because of high selenium levels. For more information, go to https://en.wikipedia.org/wiki/Gibson_Lake_(Indiana).

Jeffrey Newcomb, PE, MBA, LEED AP, has been contemplating unusual HVAC systems as a consulting engineer for over 35 years. He works for IEFM Consulting Engineers in Coal Valley, Ill., for which he is responsible for project management and design. He has degrees from the University of Illinois and The University of Iowa.

About the Author

JEFFREY NEWCOMB

Jeffrey Newcomb, PE, MBA, LEED AP, has been contemplating unusual HVAC systems as a consulting engineer for over 36 years. He works for IEFM Consulting Engineers in Coal Valley, Ill., for which he is responsible for project management and design. He has degrees from the University of Illinois and The University of Iowa.