By CONRAD JAHRLING and SCOTT ALFORD, Lync by Watts

Legionella is the leading cause of waterborne disease outbreaks in the United States, according to the Centers for Disease Control (CDC).

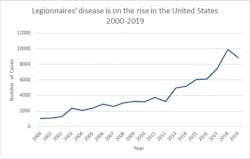

These outbreaks cost facility owners more than $1 billion annually, on average, due to lawsuits, treatment, and lost work hours. Compounding the issue is that reported U.S. cases of Legionnaires’ disease have increased by nearly nine times since 2000. (Fig. 1).

Given the severity of Legionaries’ disease and its concerning rise in cases, facility managers, building owners, and quality assurance staff must implement operating processes to reduce the risk of an outbreak. Creating and following a water management program has proven to be an effective method in all environments.

In fact, Legionella water management programs are now an industry standard for large buildings in the U.S. and are included in ANSI/ASHRAE Standard 188-2021.

Water Management Programs

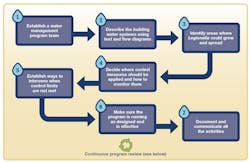

Effective water management programs incorporate procedures to mitigate the risk of Legionella growing and spreading in building water systems. According to the CDC Toolkit, a water management program should identify areas or devices in a facility where Legionella might grow or spread to people to reduce that risk. Fig. 2 outlines a typical overall framework.

Thermal Disinfection as Prevention

Included in an effective water management program is the integration of thermal disinfection as a form of remediation. Thermal disinfection has proven to be highly effective against bacteria, protozoa, and viruses. Among the benefits is that it does not lead to the formation of any known disinfection by-products (DBPs) in measurable concentrations.

Thermal disinfection is also not impaired by the presence of turbidity, natural organic matter (NOM), water hardness, or pollutants such as metals. Because it uses no chemicals, it typically does not change water properties such as taste, smell, appearance, or salinity.

Material selection in the entire domestic hot water (DHW) delivery system is critical so it can withstand thermal disinfection. With respect to the water heater, some products are designed with an engineered material that blends austenitic and ferritic steels to combine the advantages of 300 and 400 series stainless steel. This alloy makes the equipment extremely strong and highly resistant to corrosion and its negative consequences, which include being conducive to Legionella growth.

Advances to Address Legionella

An effective program should also integrate advanced hardware and software. Fortunately, advances have been made, particularly to domestic water systems (Fig. 3), that mitigate the growth of Legionella and similar pathogens.

Facility owners and managers should consider the following features when selecting a water wellness solution to address waterborne pathogens:

System Supply and Recirculation Protection - A 3-stage process helps prevent pathogen growth. Water passes through a 5-micron particulate filter, then through an anti-scale device incorporating Template-Assisted Crystallization (TAC) to agglomerate multivalent hardness ions. TAC is superior, as it converts dissolved water hardness and minerals into inert microscopic crystals. Once crystalized, they lose their ability to attach themselves to internal plumbing surfaces.

Recirculated water returns to a separate internal branch to filter and UV disinfect, for ongoing protection without the need for chemical residuals. UV inactivation is proven to prevent replication of microbes, resulting in up to 6-log reduction (cold water; 70°F / 21°C) of Legionella bacteria and reduction of common waterborne pathogens at the rated flow rates through the unit;

Biofouling Reduction – The inclusion of the TAC anti-scale subsystem reduces the creation of scale and surfaces, so biofilm has no place to affix. The 5-micron sediment filtration minimizes the surface area and potential food sources for biofilm to generate and sustain itself;

Water Heater Disinfection – Advanced water heaters thermally disinfect stored water and self-circulate on a schedule to quickly treat internal surfaces;

Building Plumbing Disinfection - Elevating the water temperatures for designated periods can penetrate the insulating biofilm and reduce the pathogens in a building’s water system;

Alerts and Communication – In an urgent maintenance situation, prompt action is required. Emergency alerts and maintenance notes can be immediately sent to designated personnel to quickly mitigate the risks of a situation;

ASHRAE 188-2021 Documentation – Part of a building’s water management program’s compliance with ASHRAE 188-2021 is to show how ongoing control measures are implemented and the corrective actions taken after exceeding limits of the control measures. Systems should record temperatures, thermal disinfection events, cold and return water UV functionality, and corresponding maintenance needs to support the control measures.

Conclusion

Legionnaires’ disease is once again a growing concern, with cases consistently rising since 2000. Various government and industry agencies and organizations have provided guidance and standards that facility owners and managers can use to develop an effective water management program. Such programs should include integrated advanced water solutions with features to help reduce the possibilities of Legionella growing in facility water systems.

##########

About the authors

Conrad Jahrling is Product Manager for Water Wellness at Lync by Watts. He has been in the plumbing and HVAC industry for 15 years, taking products from concept through commercialization and code adoption.

Scott Alford is the National Account Manager for Healthcare for Lync By Watts. He has 30+ years of mechanical equipment experience in commercial and industrial markets. Scott is certified as ASSE 12080 Legionella Water Safety and Management Specialist.