Air quality is key to achieving acceptable indoor environments. With so many air-filter technologies and performance-rating methods, it is essential design engineers and operating personnel understand the differences between them to make fully informed decisions regarding air-filtration strategy. This article discusses recent research into filter performance and shares insights that can be gleaned from that research.

Limitations of Human Respiratory Filtration and the Role of Mechanical Filtration

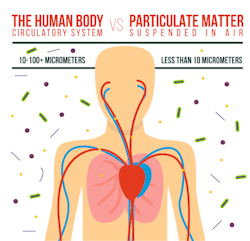

Particulate matter (PM) consists of microscopic solid particles or liquid droplets that are suspended in air. The U.S. Environmental Protection Agency says the size of particles suspended in air is linked directly to the particles’ potential to cause health issues.1 The human body has provisions, such as the nose, to naturally filter some PM. Particles larger than 100 µm tend to be too heavy to inhale, while particles in the range of 10 to 100 µm typically are unable to navigate all of the turns in the body’s respiratory passageways and are filtered by nasal hairs, nasal mucosa, or mucus-covered ciliated epithelium in the bronchi and bronchioles.2 The body, however, is unable to sufficiently filter very small PM. Particles less than 10 µm in diameter (PM10) are of particular concern because of their tendency to penetrate deep into the lungs and their potential to make their way into the bloodstream. Health issues that have been linked to PM pollution include:

- Premature death in people with heart or lung disease.

- Nonfatal heart attacks.

- Irregular heartbeat.

- Aggravated asthma.

- Decreased lung function.

- Increased respiratory symptoms (e.g., irritation of airways, coughing, difficulty breathing).

Contaminants smaller than PM10 and larger than PM2.5 often are referred to as “coarse particles.” Particles PM2.5 and smaller commonly are referred to as “fine particles.” Sources of coarse particles include dust from paved and unpaved roadways and dust-generating processes and industries, such as crushing and grinding operations. Fine particles often are found in smoke and haze, such as smog. Processes involving combustion, such as motor vehicles, power plants, and wood burning, are common sources of fine-particle pollution.

ASHRAE Air-Filtration Performance-Rating Standards

During the mid-1970s, ASHRAE formed a committee to develop a standard for evaluating and rating air-filtration performance. In 1976, that standard—ASHRAE 52—was published.

In 1992, ASHRAE Standard 52 evolved into ASHRAE Standard 52.1, Gravimetric and Dust-Spot Procedures for Testing Air-Cleaning Devices Used in General Ventilation for Removing Particulate Matter. The performance metrics included:

- Atmospheric dust-spot efficiency, a measure of a filter’s ability to remove atmospheric dust from test air (percent).

- Arrestance, a gravimetric measure of a filter’s ability to remove synthetic dust from test air (percent).

- Dust-holding capacity, determined by the product of the quantity of synthetic test dust fed to a test filter and its average arrestance (grams).

Dust-spot efficiency and arrestance are averaged over the course of a dust-loading procedure. Dust loading is used to simulate the collection of dust on a filter over a controlled period of time for the purpose of generating normalized test data. The ASHRAE Standard 52.1 test procedure specifies a synthetic mixture of fine test dust and cotton linters.

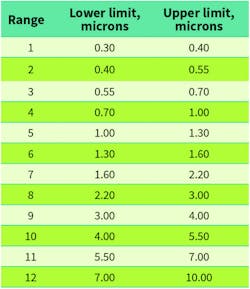

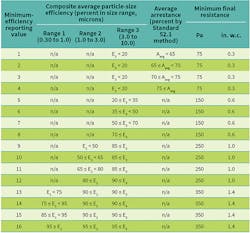

In 1999, ANSI/ASHRAE Standard 52.2, Method of Testing General Ventilation Air Cleaning Devices for Removal Efficiency by Particle Size, was published. ANSI/ASHRAE Standard 52.2 presents air-filtration performance in terms of minimum-efficiency reporting value (MERV). The testing methodology for determining an air filter’s MERV include:

The tighter the control of test-air quality, the higher the degree of precision in testing air filters. With the atmospheric test air used in the method of test prescribed in ASHRAE Standard 52.1, results can be impacted by seasonal and local environmental conditions.

With 12 particle-size ranges, designers and operators have the ability to select air filters for specific contaminants they want to remove from an air stream. For example, if the contaminant of concern is pollen, which ranges in size from 5 to 15 µm, with an average size of 7 µm, a designer or operator would select a filter in Range 12 (Table 1). If the contaminant of concern is mycobacterium tuberculosis, which ranges in size from 1 to 5 µm, with an average size of 0.7 µm, a designer or operator would select a filter in Range 3 (Table 1).

Aside from a focus on particle size, ANSI/ASHRAE Standard 52.2 differs from ASHRAE Standard 52.1 in that it provides performance values based on initial installed performance. Over time, as air filters become loaded, they tend to increase in efficiency; thus, reporting initial filtration performance yields more conservative values.

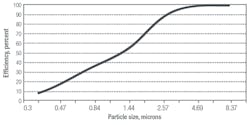

Air-filtration-performance test reports include a graph displaying initial filter efficiency through all 12 ranges of particle size (Figure 1).3

MERV is a function of filtration performance over three particle-size groups:

- E1, which represents the average minimum particle-size removal efficiency (PSE) for the four size ranges from 0.30 to 1.0 µm.

- E2, which represents the average minimum PSE for the four size ranges from 1.0 to 3.0 µm.

- E3, which represents the average minimum PSE for the four size ranges from 3.0 to 10.0 µm.

These categories represent air-filtration performance spanning the 12 particle-size ranges shown in Table 1. See Table 2 for MERV parameters. See Table 3 for typical contaminants and applications for various MERV ratings.

Electrostatic Charge

While ANSI/ASHRAE Standard 52.2 represents the latest in air-filtration-performance evaluation, it is not perfect. The performance of a filter utilizing electrostatic capture may be high initially, but inconsistent through the filter’s service life because of the erosion of electrostatic charge as the filter loads with contaminants. In 2008, ANSI/ASHRAE Standard 52.2 Appendix J, a non-mandatory informative alternate test procedure to address the concern of electrostatic-media properties yielding potentially misleading MERV results, was released. Appendix J substitutes the ASHRAE synthetic-dust mixture with potassium chloride (KCl) to better simulate the aerosol-size particle distribution air filters commonly observe in real-world applications.

As far back as 1999, ANSI/ASHRAE Standard 52.2 committee members were aware of the limitations of the test procedure with respect to electrostatically charged filter media. The 1999 version of ANSI/ASHRAE Standard 52.2 states: “Some fibrous-media air filters have electrostatic charges that may either be natural or imposed upon the media during manufacturing. Such filters may demonstrate high efficiency when clean and drop-in efficiency during their actual-use cycle. The initial conditioning step of the dust-loading procedure described in this standard may affect the efficiency of the filter, but not as much as would be observed in actual service. Therefore, the minimum efficiency during test may be higher than that achieved during actual use.”

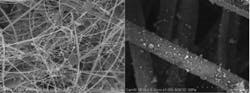

The use of KCl in Appendix J is the result of ASHRAE research and industry input. Two substantial research projects that contributed to the development of Appendix J are ASHRAE Research Project 1189, Investigations of Mechanisms and Operating Environments That Impact the Filtration Efficiency of Charged Air Filtration Media, and ASHRAE Research Project 1190, Develop a New Loading Dust and Dust Loading Procedures for the ASHRAE Filter Test Standards 52.1 and 52.2. These research projects have shown that coarse-fiber media, which is electrostatically charged, performs differently from fine-fiber media, such as fiberglass, in real-world applications.

Coarse-fiber media relies on an electrostatic charge to achieve published performance. This is concerning because very fine particulate (less than 1.0 µm in size) will erode the charge and diminish filtration performance over time. Specifying the Appendix J test procedure to determine MERV rating will show the reduction in performance of a filter relying on electrostatically charged media compared with the filter’s published performance using the mandatory ANSI/ASHRAE Standard 52.2 test method. Specifying engineers should look for the MERV-A rating, which shows air-filter performance using the ANSI/ASHRAE Standard 52.2 Appendix J test procedure. If a designer intends to use a MERV 13 filter, then he or she should look for the corresponding MERV-A 13-A rating on the air-filter product.

Filters utilizing fine-fiber media that rely on mechanical principles to remove contaminants from an air stream tend to yield more reliable performance over their service life. The filtration efficiency of these filters actually increases over time as the filters load with contaminants.

Conclusion

Achieving acceptable indoor-air quality requires an understanding of the fundamentals of air-filtration requirements and performance. Substantial research has been invested, yielding the modern performance test methods and benchmarks we have today. Thanks to ASHRAE and industry involvement, designers and operators have robust tools to evaluate and properly select the correct filter for an application. Not all air filters yield the same real-world performance under the mandatory ANSI/ASHRAE Standard 52.2 method of test. Designers should consider specifying the ANSI/ASHRAE Standard 52.2 Appendix J test procedure to gain a more thorough understanding of air-filtration performance throughout the service life of a filter.

References

1) EPA. (n.d.). Health. Retrieved from https://www3.epa.gov/pm/health.html

2) EHP. (2006, February). Particles in practice: How ultrafines disseminate in the body. EHP Student Edition, p. A758.

3) Camfil Farr. (n.d.). ASHRAE testing for HVAC air filtration. Retrieved from http://www.camfil.com/Global/Documents/Brochure/Standards/ASHRAE52.pdf

Nathan L. Ho, PE, is a mechanical engineer for P2S Engineering Inc. specializing in HVAC- and control-system design with a focus on performance and efficiency. His experience includes design, engineering, construction administration, commissioning, and project management for an extensive range of facilities, including laboratories, data centers, high-performance commercial buildings, and utility plants.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].