Is ice-based thermal-energy storage (TES) really green? Although the success of ice-based TES in reducing energy costs has been substantiated, there are differing opinions within the HVAC community regarding whether TES is a green technology. As one would expect, manufacturers of related equipment generally claim that ice-based TES reduces emissions, while outside authorities have disagreed on record.1,2,3 Because TES often can offer heat-recovery opportunities—such as for domestic water heating—its environmental friendliness is a legitimate concern. So, is ice-based TES economically and environmentally justifiable? How can we determine if the benefits gained by utilizing ice-based or any other type of TES are worth the resources used?

Electric Chillers and TES

Electric chillers have been utilized for ice-based TES since the 1980s. This method can decrease costs by shifting electric energy consumption from higher-priced peak rates to less-costly off-peak (predominantly nighttime) rates. Chilled water is used to produce ice during off-peak periods, which is melted to absorb heat in conditioned spaces during peak periods, thus reducing peak chiller loads. This method also may reduce first costs in new construction by allowing equipment downsizing.

But is ice-based TES really a green/sustainable solution? On one hand, it consumes more energy than conventional chilled-water cooling. And because the sub-freezing temperatures required for ice production are lower than those generally used for space cooling (typically 38˚F to 45˚F), the chillers may be operating at a lower mechanical efficiency. Because frequent cycling reduces overall efficiency, higher energy consumption can be offset at least partially if the chillers are operating continuously at a constant load. It often is presumed that cooling towers experience lower air temperatures at night and that decreased pumping horsepower—as well as more efficient condenser-water cooling—help balance chiller-efficiency losses because of lower flows resulting from a wider temperature range. With a higher delta-T across the cooling coil, fewer rows and, therefore, a lower pressure drop and decreased fan-motor horsepower would be expected. Finally, off-peak-produced power is arguably "cleaner."

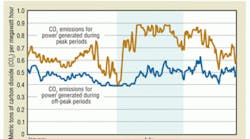

The California Energy Commission concluded that a reduction in source fuel typically results in a reduction of the greenhouse-gas emissions produced by a power plant.4 Data from one utility, Southern California Edison, shows that carbon-dioxide (CO2) emissions are 40-percent lower for power generated during off-peak periods (Table 1). However, this may not always be the case. For example, if a base-load power plant is coal-fired and the corresponding intermediate and/or peak-load plant is gas-fired, the off-peak power may be "dirtier" than the peak-load plant's output. In any case, chillers with lower efficiencies at sub-freezing evaporator temperatures will require larger on- to off-peak differentials—in energy and demand rates—if the project is going to be economically viable.5 If a TES project does not make good economic sense, its sustainability—or lack thereof—is moot.

Determining TES Sustainability

Several often conflicting factors that influence the sustainability of a project, such as higher energy consumption, differing chiller efficiencies, and potentially cleaner off-peak power generation, must be examined to determine whether an ice-based TES system is green. Reviewing a couple of actual ice-based TES installations can help give a better understanding of TES-system sustainability.

Beijing demonstration building. Completed in late 2003 and occupied in 2004, a joint U.S./China demonstration building in Beijing was the first Chinese office building to achieve Leadership in Energy and Environmental Design (LEED) Gold certification from the U.S. Green Building Council.6 The nine-story, 140,000-sq-ft building has an ice-based TES system in its basement. Primary cooling and ice-making is provided by two high-efficiency screw chillers, each rated for 100 tons with a coefficient of performance of 4.4. The TES system can produce 50 tons of ice per night. Using data from summer 2005, the additional off-peak energy consumption for the system averaged just over 9,000 kwh per month, resulting in whole-building off-peak energy consumption of approximately 21,000 kwh per month. With 7,700 tons of stored cooling per month, the peak cooling load was reduced by 7,000 tons per month, resulting in a reduction of peak electric-energy consumption of 6,100 kwh per month for a monthly net savings of approximately $609. Although there was some modest economic benefit, the real question is whether this particular TES system is green.

If we assume a source-site ratio of 3.34 (the U.S. average for the same period),7 then the additional 9,000 kwh per month needed for the TES system required consumption of approximately 30,000 kwh per month for generation. If there were no difference in the fuels fired during peak and off-peak periods, then the TES system would have produced the equivalent of an additional 22 metric tons of CO2 per month. However, if we assume an emissions reduction similar to that shown in Table 1, the additional off-peak energy consumption of 9,000 kwh per month actually was lower than the peak energy consumption of 6,100 kw per month when a 40-percent emissions penalty was considered. When peak and off-peak carbon footprints were calculated, peak energy consumption was greater than 10,000 kwh per month. In that case, the TES system would be demonstrably sustainable, both environmentally and—at a peak-to-off-peak differential of greater than 4—economically. In this example, the break-even point is a peak-to-off-peak emissions reduction of approximately 32 percent.

Page 2 of 2

Nova Southeastern University. A new central energy plant at the main campus of Nova Southeastern University (NSU) in South Florida includes ice-based TES. With more than 28,000 students, NSU is the sixth-largest independent not-for-profit university in the United States. The new plant is expected to serve the entire 300-acre Fort Lauderdale-Davie campus. The first phase, which went online in November 2009, included two 2,300-ton compound chillers and 30 ice coils in field-erected concrete tanks rated for 17,000 ton-hr of capacity. When completed, the plant will have a total capacity of 11,500 tons of chilled water with 68,000 ton-hr of TES, making it one of the largest TES systems in the United States.8

When in ice-building mode, the design-efficiency penalty for each chiller is approximately 13 percent (2,300 tons derated by 13 percent equals 2,000 tons). Based on a peak-to-off-peak differential of 1.6 (calculated from actual electric energy billing), the economics appear viable. However, unless the local utility's off-peak power-generation emissions are 13-percent less than their on-peak levels, the process is not truly sustainable. According to the local utility, Florida Power & Light, only 8 percent of its current generating capacity is fueled by oil and coal; the remaining 92 percent is from natural-gas, nuclear, and renewable sources, resulting in a CO2 emissions rate that is 59 percent of the U.S. industry average.9 While laudable, this means that the best case for peak-to-off-peak emissions reduction is limited to 8 percent, which by itself is not sufficient to offset the efficiency penalty.

Fortunately, the project's anticipated overall efficiency improvements are more than what is needed to offset the 5-percent increase in source CO2 emissions. The improvements are a result of the reduction in cooling-tower-fan horsepower (two installed two-cell, 3,000-gpm-per-cell cooling towers were designed for the capacity requirements of all of the chiller/TES-system operation modes), the ability to optimize performance by using any or all of the chillers in any mode (chiller, charge, or discharge/off), and the means to vary the chilled-water/brine-solution temperature from 18˚F to 38˚F, depending on mode and load.

Because we are more concerned with sustainability than economics, first cost is not addressed in this analysis. However, one would hope that good design practices would include some degree of equipment diversity that would help offset the expected increase in construction costs. And because simple payback periods based solely on avoided energy costs would be long, this type of project could be a good candidate for a return-on-investment analysis using a capital-recovery-factor-based cost-to-benefit ratio.10

Conclusion

A relatively simple analysis of only two installations cannot definitively address the overarching question of whether ice-based TES represents a sustainable solution. However, it can—and does—confirm that these systems usually have the potential to reduce energy costs and, on a case-by-case basis (depending primarily on plant design and the local utility's infrastructure), may be truly green.

Going forward, the impact of renewable energy on the sustainability of these types of solutions probably should be addressed in some detail. If, in either of the two examples given, the electric energy required for chiller-plant operation had been provided—or augmented—by on-site generation using a renewable-energy source, such as solar or wind, project sustainability could have been demonstrated easily. In that case, the emphasis would have been on optimizing the availability of the energy source—either sunlight or wind—rather than on shifting load from peak to off-peak hours of operation. In that instance, the model theoretically could make ice during the day and melt it at night.

References

1) Ice thermal storage. (n.d.) Retrieved from http://www.baltimoreaircoil.com/english/products/ice/tsum/index.html

2) Thermal energy storage benefits. (n.d.) Retrieved from http://www.calmac.com/benefits/

3) Wiens, J. (2008, June). Thermal energy storage. Buildings.

4) California Energy Commission. (1996). Source energy and environmental impacts of thermal energy storage. Sacramento, CA.: California Energy Commission.

5) Henze, G., Krarti, M., & Brandemuehl, M. (2003, February). Guidelines for improved performance of ice storage systems. Energy and Buildings, pp. 111-127.

6) Xu, P., Huang, J., Jin, R., & Yang, G. (2007, January). Measured energy performance of a US-China demonstration energy-efficient office building. ASHRAE Transactions, 113, 56-64.

7) U.S. Environmental Protection Agency. (2009). U.S. annual non-baseload CO2 output emission rate: Year 2005 data. Washington, DC: U.S. Environmental Protection Agency.

8) Hill York. (2009). Building a green-er NSU. Fort Lauderdale, FL: Hill York.

9) FPL Group Inc. (2009). Sustainability report 2009. Juno Beach, FL: FPL Group Co.

10) Clark, L. (2009, January). Engineering economics goes green. Engineered Systems, pp. 82-84.

11) Struble, L., & Godfrey, J. How sustainable is concrete? (n.d.) Retrieved from www.cptechcenter.org/publications/sustainable/strublesustainable.pdf

Did you find this article useful? Send comments and suggestions to Associate Editor Megan White at [email protected].

Larry Clark, LEED AP, is director of corporate business development for air-conditioning contractor Hill York. Previously, he served as president, vice president of sales and marketing, and regional sales manager for MEPCO and regional sales manager for Vapor Power.

Construction Consumes Energy

It should be noted that this article does not attempt to address the embodied energy associated with the construction of ice-storage tanks. When fully built-out, the NSU plant will have four concrete tanks each measuring approximately 106 ft by 65 ft by 42 ft. That represents a significant amount of concrete using cement that requires nearly 5 mj per kilogram to produce (approximately 2,150 Btu per pound), which does not include the energy required to manufacture the rebar that also must be incorporated.11