Rooftop variable-air-volume (VAV) systems are used to provide comfort in a wide range of building types and climates.1 This kind of system consists of a packaged rooftop air conditioner that serves several individually controlled zones. Each zone has a VAV terminal unit that is controlled by a temperature sensor. This article will discuss HVAC-system control strategies that can be used to save energy in rooftop VAV systems.

Optimal Start/Stop

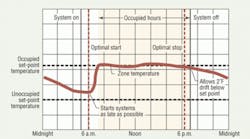

In some buildings, a simple time clock or time-of-day schedule is used to start and stop the HVAC system. When a building is expected to be unoccupied, the system is shut off and the temperature allowed to drift away from the occupied set point. The time at which the system is to restart typically is set to ensure that the indoor temperature reaches the desired occupied set point prior to occupancy on either the coldest or warmest morning of the year. As a result, for most days, the system starts much earlier than needed. In turn, this increases the number of operating hours and system energy use.

An alternative approach is a strategy called "optimal start." This strategy utilizes a building-automation system (BAS) to determine the length of time required to bring each zone from its current temperature to the occupied set-point temperature. The system waits as long as possible before starting, so the temperature in each zone can reach the occupied set point just in time for occupancy (Figure 1).

This optimal starting time is determined using the difference between the actual zone temperature and occupied set point. It compares this difference with the historical performance of the zone warming up or cooling down.

The optimal-start strategy reduces the number of system operating hours and saves energy by avoiding the need to maintain the indoor temperature at the occupied set point even though the building is unoccupied.

A related strategy is called "optimal stop." As mentioned previously, at the end of an occupied period, the HVAC system is shut off and the temperature allowed to drift away from the occupied set point. However, the building occupants may not mind if the indoor temperature drifts just a few degrees before they leave for the day.

Optimal stop uses a BAS to determine how early heating and cooling can be shut off for each zone so that the indoor temperature drifts only a few degrees from the occupied set point (Figure 1). In this case, only cooling and heating are shut off. The supply fan continues to operate, and the outdoor-air damper remains open to continue ventilating the building.

The optimal-stop strategy also reduces the number of system operating hours, saving energy by allowing indoor temperatures to drift early.

Fan-Pressure Optimization

As cooling loads change, VAV terminals modulate to vary airflow supplied to the zones. This causes the pressure inside the supply ductwork to change. In many systems, a pressure sensor is located approximately two-thirds of the distance along the main supply duct. The rooftop unit varies the capacity of the supply fan to maintain the static pressure in this location at a constant set point. With this approach, however, the system usually generates more static pressure at part load than necessary.

When communicating controllers are used on VAV terminals, it is possible to optimize this static-pressure control function to minimize duct pressure and save fan energy. Each VAV-unit controller knows the current position of its air-modulation damper. The BAS continually polls these individual controllers, looking for the VAV terminal with the damper that is open the widest (Figure 2). The supply fan's set point then is reset to provide just enough pressure so that at least one damper is nearly wide open. This results in the supply fan generating only enough static pressure to push the required quantity of air through this "critical" VAV-terminal unit.

This control strategy, which sometimes is called "fan-pressure optimization," has several benefits:

-

Reduced supply-fan energy use. At part-load conditions, the supply fan is able to operate at a lower static pressure and consume less energy (Figure 3).

-

Lower sound levels. The supply fan does not generate as much static pressure and typically generates less noise. In addition, with lower pressures in the supply duct, the dampers in the VAV terminals open wider, resulting in less regenerated noise.

- Reduced risk of fan surge. With the fan operating at a lower pressure when delivering reduced airflow, the fan operating point is kept farther away from the surge region (Figure 3).

Supply-Air-Temperature Reset

In a VAV system, it is tempting to raise the supply-air temperature at part-load conditions to save compressor and/or reheat energy. Increasing supply-air temperature reduces compressor energy because it allows a compressor to operate at a warmer suction temperature. The corresponding higher suction pressure reduces compressor lift, reducing the power required.

An air-side economizer is more beneficial when supply-air temperature is reset. When outdoor air is cooler than the supply-air-temperature set point, compressors are shut off and outdoor- and return-air dampers modulate to deliver the desired supply-air temperature. A warmer supply-air-temperature set point allows the compressors to be shut off sooner and increases the number of hours in which the economizer is able to provide all of the necessary cooling.

When supply airflow has been reduced to a VAV terminal's minimum setting, raising supply-air temperature decreases the use of reheat in those zones that have very low cooling loads. However, because the supply air is warmer, zones that require cooling will need more air to satisfy the cooling load. This increases supply-fan energy.

Finally, in non-arid climates, warmer supply air means less dehumidification at coils and higher humidity levels in zones. If dehumidification is a concern, use caution when implementing this strategy. Table 1 contains some general guidance on determining when this strategy can provide the most benefit.2

TABLE 1. Guidance concerning supply-air-temperature reset.

Supply-air-temperature reset should be implemented so that it minimizes overall system energy use. This requires consideration of the tradeoff among compressor, reheat, and fan energy, as well as the impact on space humidity levels. These competing issues often are balanced by first reducing supply airflow, taking advantage of the significant energy savings that come from unloading the fan. Once fan airflow has been reduced, the supply-air temperature can be raised to minimize reheat energy and enhance the benefit of the air-side economizer.

Figure 4 is an example of a supply-air-temperature-reset strategy that is based on a changing outdoor dry-bulb temperature. When the outdoor temperature is warmer than 70?F, no reset takes place, and the supply-air-temperature set point remains at the design value of 55?F. When it is that warm outside, outdoor air provides little or no cooling benefit for economizing. In most zones, the cooling load is likely high enough that reheat is not required to prevent overcooling. In addition, the colder (and drier) supply air allows the HVAC system to provide sufficiently dry air to the zones, improving part-load dehumidification.

When the outdoor temperature is between 60?F and 70?F, the supply-air-temperature set point is reset at a 2-1 ratio. That is, for every 2?F change in outdoor temperature, the set point is reset 1?F. In this range, supply-air-temperature reset enhances the benefit provided by the economizer and it is likely that some zone-level reheat can be avoided.

Finally, when the outdoor temperature is colder than 60?F, no further reset occurs, and the supply-air-temperature set point remains at 60?F. Limiting the amount of reset to 60?F allows the system to satisfy the cooling loads in interior zones without needing to substantially oversize VAV terminals and ductwork.

Alternatively, some systems reset the supply-air-temperature set point based on the temperature in the "critical" zone. (This is the zone at greatest risk of overcooling, which would require activating local reheat.) In these systems, a BAS monitors the temperature in all zones, finding the critical zone that is closest to the heating set point. A rooftop unit then resets the supply-air-temperature set point to prevent the critical zone from needing to activate reheat.

When considering using supply-air-temperature reset in a rooftop VAV system, first analyze the system to determine if the savings in compressor and reheat energy will outweigh the increase in fan energy. If higher space humidity levels are a concern, consider disabling the reset function when it is humid outside or provide a humidity sensor in one or more zones to override the reset function whenever indoor humidity exceeds some maximum limit.

For interior zones with near-constant cooling loads during occupied periods, design airflows should be calculated based on the warmer, reset supply-air temperature (60?F in the example from Figure 4). While this may require larger VAV terminals and ductwork, it allows the use of supply-air-temperature reset during cooler weather, while still providing the necessary cooling to weather-independent interior zones.

FIGURE 4. A supply-air-temperature-reset strategy based on a changing outdoor dry-bulb temperature.

It also is best to design a rooftop VAV system's air-distribution system for low-pressure losses and use the fan-pressure-optimization strategy to minimize the fan-energy penalty that accompanies a warmer supply-air temperature.

Ventilation Optimization

In a typical VAV system, the rooftop unit delivers fresh outdoor air to several individually controlled zones. Demand-controlled ventilation (DCV) involves resetting intake airflow in response to variations in zone population. One approach to optimizing ventilation in a multiple-zone VAV system is to combine the various DCV strategies at the zone level (using each where it fits best) with ventilation reset at the system level. Ventilation reset involves resetting intake airflow based on variations in system ventilation efficiency.

For this approach, carbon-dioxide (CO2) sensors are installed only in zones that are densely occupied and experience widely varying patterns of occupancy. For the example building in Figure 5, CO2 sensors are installed only in the conference room and lounge. These zones are the best candidates for CO2 sensors and provide the "biggest bang for the buck." These sensors reset the ventilation requirement for their respective zones based on measured CO2.

While DCV strategies commonly employ CO2 sensors, occupancy sensors or time-of-day (TOD) schedules also can be used. Zones that are less densely occupied or have a population that varies only a little (such as private offices, open-plan office spaces, or many classrooms) probably are better suited for occupancy sensors. In Figure 5, each of the private offices has an occupancy sensor to indicate when the occupant is present. When unoccupied, the controller lowers the ventilation requirement for the zone. Occupancy sensors are relatively inexpensive, do not need to be calibrated, and already are used in many zones to control lights.

FIGURE 5. Zone-level demand-controlled-ventilation strategies.

Finally, zones that are sparsely occupied or have predictable occupancy patterns can be controlled efficiently through the use of a TOD schedule. The schedule can indicate when the zone normally will be occupied/unoccupied or be used to vary the zone ventilation requirement based on anticipated population.

These various zone-level DCV strategies can be used to reset the ventilation requirement for their respective zones for any given hour. The zone-level control then is tied together using ventilation reset at the system level (Figure 6).

FIGURE 6. System-level ventilation-reset strategy.

In addition to resetting a zone's ventilation requirement, the controller on each VAV terminal continuously monitors the primary airflow being delivered to the zone. A BAS periodically gathers this data from all of the VAV terminals and solves the ventilation-reset equations (prescribed by ANSI/ASHRAE Standard 62.1, Ventilation for Acceptable Indoor Air Quality) to determine how much outdoor air must be brought in at the rooftop unit to satisfy all of the zones served. Finally, the BAS sends this outdoor-airflow set point to the rooftop unit, which modulates a flow-measuring outdoor-air damper to maintain the new set point.

In a direct-digital-control/VAV system, this strategy is fairly easy to implement because the necessary real-time information already is available digitally. Combining DCV at the zone level with ventilation reset at the system level has many benefits, including:

-

Ensuring that zones are ventilated properly without requiring a CO2 sensor in each. CO2 sensors are used only in the zones in which they can have the most benefit. This minimizes installation costs and avoids the periodic calibration and cleaning required to ensure proper sensor operation. For the other zones, occupancy sensors and TOD schedules can be used to reduce ventilation.

-

Enabling documentation of actual ventilation-system performance. The VAV controllers communicate each zone's ventilation airflow to the BAS, even for the zones that do not have CO2 sensors. The BAS can be used to generate reports showing ventilation airflow in every zone, hour by hour.

- Using system-level ventilation-reset equations that are defined in an industrywide standard. Using equations from ASHRAE Standard 62 improves the ability to defend the control strategy's use.

Conclusion

The impact of any energy-saving strategy on the operating costs of a specific building depends on climate, building usage, and utility costs. Building-analysis tools can be used to analyze these strategies and convert energy savings to operating-cost savings and help make financial decisions.

Figure 7 shows the potential energy savings of using these various strategies in an office building with a typical rooftop VAV system. The optimized system uses the optimal-start, supply-air-temperature-reset, and ventilation-optimization strategies discussed in this article. In addition, the supply fan is controlled based on fan-pressure optimization, rather than a constant set point in the ductwork. The optimized rooftop VAV system would reduce HVAC energy use by about 30 percent if the building were located in Atlanta and Los Angeles and by 33 percent if it were located in Minneapolis.

FIGURE 7. HVAC energy savings from optimized system controls.

There is real potential to save energy in rooftop VAV systems through optimized system-control strategies. This savings can reduce a building owner's operating costs and help earn points toward Leadership in Energy and Environmental Design certification.

Unoccupied Humidity Control

A VAV system typically dehumidifies effectively over a wide range of operating conditions because it continues to deliver cold, dry air at part-load conditions. As long as supply-air-temperature reset is used with caution and reheat is available for those VAV terminals that have high minimum-airflow settings or experience low cooling loads, a VAV system typically will provide supply air at a dew point that is low enough to prevent elevated indoor humidity levels during occupied periods.

However, controlling humidity levels always is a priority, not just when a building is occupied. When indoor humidity rises too high during unoccupied times, one option is to turn on the rooftop unit and dehumidify the recirculated air to about 55?F. However, there typically is little sensible load in the zones during these periods, so delivering cold air will result in overcooling. Reheat coils in the VAV terminals, and possibly a boiler and hot-water pumps, will need to be activated.

An energy-saving alternative is to equip the rooftop unit with hot-gas reheat. When after-hours dehumidification is needed, the rooftop unit turns on and diverts hot refrigerant vapor from the compressor through a refrigerant-to-air heat exchanger located in the air stream following the evaporator coil. Sensible heat is transferred from the hot refrigerant to reheat the dehumidified air leaving the evaporator.This strategy uses heat recovered from refrigeration circuits to reheat centrally and saves energy by avoiding the use of new energy to reheat remotely at VAV terminals.

References

-

Murphy, J. (2007). Rooftop VAV systems applications engineering manual (SYS-APM007-EN). La Crosse, WI: Trane.

- California Energy Commission. (2003). Advanced variable air volume system design guide. Sacramento, CA: California Energy Commission.

An applications engineer for Trane, John Murphy, LEED AP, aids engineers in the proper design and application of HVAC systems. He is a member of several American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) technical committees and a contributing author of ASHRAE's recently published "Advanced Energy Design Guide for K-12 School Buildings."