Independent third-party verification of ventilation-system components is valuable in ensuring performance and safety. This is especially true for critical laboratory exhaust systems. Air Movement and Control Association (AMCA) International Inc. certifies induced-flow-fan air and sound performance based on two established testing standards:

- AMCA Standard 260-07, Laboratory Methods of Testing Induced Flow Fans for Rating.

- ANSI/AMCA Standard 300-08, Reverberant Room Method for Sound Testing of Fans.

The AMCA 260 and 300 certified rating seals ensure a laboratory fan system will perform as stated by the manufacturer and as required for a project.

Comparing Laboratory-Exhaust-System Efficiencies

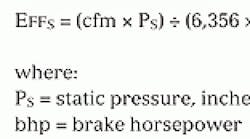

Fan static efficiency relates the air (in cubic feet per minute [cfm]) moved by a fan at a given static pressure to the energy required to move the air. The calculation for fan static efficiency (EFFS) (Equation 1) is:

In fan application engineering, it generally is accepted that airfoil-blade housed centrifugal blowers are the most efficient fan designs available, with maximum attainable static efficiencies of approximately 80 percent. For inline mixed-flow fans, the peak static efficiency is about 75 percent.

When evaluating and comparing laboratory-exhaust-fan efficiencies, other exhaust-system components (e.g., discharge stacks and nozzles) need to be considered, whether the systems being evaluated are field-built-up or factory-provided. Typically, all laboratory exhaust systems utilize a discharge stack and a high-velocity discharge nozzle, which increases the momentum of exhaust air, dispersing contaminants high above a roof line. This high-velocity-discharge benefit is accompanied by the cost of increased horsepower.

The pressure loss associated with high-velocity discharge is equal to the velocity pressure (PV) at the discharge (Equation 2):

For a field-built-up laboratory exhaust system, stack and nozzle static-pressure loss is not included in manufacturer performance data. It must be added to fan-inlet static pressure for a fan to be sized appropriately. For a factory-provided system (induced-high-plume-flow fan), this loss typically is included in manufacturer performance data, and only inlet static pressure is used for fan sizing.

Accurate analysis of fan-system static efficiencies requires the inclusion of high-velocity-nozzle pressure loss. For the static efficiency of induced-flow fans to be calculated, nozzle pressure loss must be added to inlet static pressure.

Induced-flow laboratory exhaust-fan systems can be categorized into two groups:

- Inline mixed flow (Figure 1).

- Housed centrifugal (Figure 2).

Comparing Induced-Flow-Fan Efficiencies

With increased focus on sustainability and energy consumption, it is important to evaluate several laboratory-exhaust-system fan types and their performance with respect to fan static efficiency. For this article, an induced-flow centrifugal fan system and two different (Manufacturer A’s and Manufacturer B’s) induced-flow inline mixed-flow fan systems will be compared. The performance requirements are from actual project documents:

- Laboratory exhaust flow: 35,524 cfm.

- System static pressure (SP): 6 in. wg.

- Nozzle velocity: 6,665 fpm.

To calculate the static efficiencies of the three fan systems, we must calculate the static-pressure loss of the high-velocity nozzle per Equation 2. This pressure loss is added to system static pressure to calculate fan static efficiency (Equation 1).

Table 1 shows the selection of fans. It includes each fan’s performance based on manufacturer data, framed in black. Fan 3 has high entrained flow and the lowest brake horsepower.

Table 2 provides additional information about the fans.

Fans 1 and 2 have efficiencies falling below the maximum of 80 percent for housed airfoil centrifugal fans and 75 percent for inline mixed-flow fans, respectively. Meanwhile, Fan 3 has a static efficiency exceeding the 75-percent maximum for inline mixed-flow fans. How could that be?

Assuming Fan 3 can exhaust the required 35,524 cfm at 6-in.-wg static pressure, the stated performance in question is the entrained airflow and nozzle velocity. Further investigation reveals the performance of fans 1 and 2 is worthy of AMCA Standard 260-07 certification, while that of Fan 3 is not.

Conclusion

To be assured stated performance is factual, specify fans and fan systems with AMCA-certified performance ratings. For induced-flow fans for critical laboratory exhaust applications, the ratings are based on testing in accordance with AMCA Standard 260-07.

References

ASHRAE. (2004). ASHRAE handbook—HVAC systems and equipment (ch. 18). Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

Jorgensen, R. (1999). Fan engineering (9th ed.). Buffalo, NY: Buffalo Forge.

The director of applied product sales for Greenheck Fan Corp., Anthony J. Rossi has more than 30 years of experience in industrial ventilation, through which he has gained extensive knowledge of laboratory fume exhaust. He is an active member of ASHRAE Technical Committee 9.10, Laboratory Systems; has served on ASHRAE and Air-Conditioning & Refrigeration Institute standards-development committees; and has chaired the education committee of ASHRAE Central Indiana Chapter. He has bachelor’s and master’s degrees in mechanical engineering from the New Jersey Institute of Technology.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].