All HVAC installations should try to reach two fundamental objectives. First, they should deliver the specified comfort level. Second, they should reach the first objective using a minimum amount of energy, thereby maximizing efficiency and minimizing costs. In theory, current building-management-system technology can help achieve these objectives, but, in practice, even the most sophisticated control system can have problems that lead to reduced comfort and higher operating costs. In many cases, these problems are found in hydronic systems.

Symptoms of an Unbalanced System

A hydronic problem usually reveals itself when building occupants report an indoor climate issue. Indoor climate problems are quite common. In fact, two out of three buildings experience indoor climate issues. Common indicators of hydronic problems include:

-

A space that is too hot in one area and too cold in another.

-

A difficult initial startup that takes substantially longer in some rooms following an off-hours setback.

-

Installed power that is not deliverable at intermediate and/or high loads.

-

Higher-than-expected energy costs.

-

Room-temperature fluctuations or room temperatures that do not reach the required set point at high loads.

-

Control-valve and actuator maintenance problems.

-

Poor system delta-T.

To solve temperature issues, occupants often compensate by using space heaters, opening windows, and adjusting thermostat settings. Maintenance managers sometimes attempt to correct problems by installing larger pumps, resizing components, changing off-hour setback and initial startup times, and/or adjusting flow in system mains, branch lines, and circuits.

Such “fixes” typically are costly and ineffective. They serve as a bandage and ignore the root of the problem. By only addressing a symptom, they can create a larger problem. Tenants who were comfortable previously may begin to complain.

Engineers typically design HVAC systems with extra capacity to meet heating and cooling needs, but the challenge is using that energy in the most efficient manner possible. The key to HVAC-system effectiveness and efficiency, as well as the solution to these symptoms, often resides in a hydronic system. This article will discuss the three key conditions to achieving perfect hydronic control:

-

Design flow at terminal units.

-

Differential pressure across control valves.

-

Flow compatibility.

Key No. 1: Design Flow at Terminal Units

The first key to hydronic control is design-flow availability. Design flow must be available at all terminal units under design conditions.

Simply indicating design flows on drawings is not sufficient. For design flows to be obtained, they must be measured and adjusted. In theory, it is possible to obtain correct flows by sizing the plant carefully, but installation does not always match design. Some oversizing occurs because components must be selected from existing commercial product lines. For example, control valves with exactly the required valve capacity typically are not available on the market. As a result, most control valves are sized incorrectly. Total opening of control valves cannot be avoided in many situations, such as during startup or large disturbances, when some thermostats are set at minimum/maximum value, or coils have been undersized. In these cases — and when balancing valves are not in place — overflow will occur in some circuits.

Additionally, some components are not known during design because the contractor selects them at a later stage. Original plant designs commonly are modified during installation. Hydronic balancing enables required flows to be obtained in actual installations and compensates for incorrect sizing.

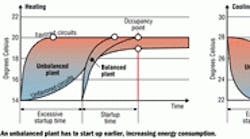

Without balancing, initial circuits may experience overflow, which creates underflow in other circuits. To avoid occupant complaints, pump head usually is increased, sometimes increasing overflow and reducing underflow. The delta-T in circuits with overflow then becomes poor.

Page 2 of 4

Increasing pump head to reduce underflow wastes energy and, therefore, does not maximize efficiency or minimize costs. Additionally, overflow means water velocity may be higher than expected. High water velocity can lead to erosion in piping and other system components. Furthermore, the control valves of overflowing circuits operate with very short open/close cycles, which can reduce actuator life.

Next, supply water is increased during heating periods and decreased during cooling periods. Although unfavored rooms — rooms farthest from the pump — will start to feel comfortable, tenants in favored rooms will become uncomfortable, resulting in wasted energy and increased carbon-dioxide emissions.

One solution is to balance the system at design conditions, which guarantees that all terminals receive design flow.

To perform systematic balancing with optimal pressure-drop results, hydronic distribution piping must be decomposed into hydronic modules. One module is formed by connecting several circuits to supply and return pipes. Each circuit has its own balancing valve, and each module has a common balancing valve called a partner valve.

Hydronic modules can be balanced via one of three methods: proportional, compensated, or computerized.

Adapted from air-system-balancing methodologies, the proportional method is not optimal when dealing with pressure drops. The compensated method is designed for applications with balancing valves. The computerized method incorporates software based on the compensated method into a computerized balancing instrument (CBI). Using the computerized method, one individual can balance an entire plant using a single CBI.

After a plant's differential-pressure measurements are taken, the computerized method calculates the correct balancing-valve settings. The CBI detects the index circuit in the module and allocates a pressure drop of 1 ft (0.5 psi) — the minimum pressure drop required for reliable flow measurements — for the circuit's balancing valve.

The other balancing valves' settings then are calculated to obtain a set point for the module's circuits. The determined values are pre-set on the balancing valves.

When all of the modules have been balanced individually, they are balanced in relation to one another using the same procedure. The partner valves' settings also are determined.

Finally, the total design flow is adjusted with the main balancing valve, which accepts and measures all of the system's overpressure. If the overpressure is too high, a smaller pump can be installed to reduce pumping costs.

When the operation is complete, design flows are available at all terminals. The software compiles and provides a list of settings, differential pressure, and water flows for each balancing valve.

Many hydronic problems can be detected through balancing, including:

- Clogged filters or valves.

- Incorrectly mounted terminal units or exchangers.

- Damaged or improperly connected pipe.

- Partially closed shutoff valves.

- Incorrectly installed check valves or pumps.

Balancing exposes these types of flaws while they still can be repaired inexpensively.

Key No. 2: Differential Pressure Across Control Valves

The second key to hydronic control is the control of differential pressure. Differential pressure must not vary too much across control valves. Although this condition is specific to variable-flow systems in which a plant's differential pressures may vary considerably during operation, it can be avoided by utilizing differential-pressure control.

An important measure of hydronic-design quality is the relationship between the control signal and the thermal power resulting from the coil. Known as the circuit characteristic, this process determines the system's controllability. The circuit characteristic is a combination of several factors, such as:

- Actuator characteristic

Typically linear, the actuator characteristic signifies the relationship between the incoming control signal from the controller to the actuator and the resulting valve lift.

- Inherent valve characteristic

Representing the relationship between the valve opening and valve capacity, the inherent valve characteristic depends on the control valve's mechanical design.

- Terminal characteristic

Variable depending on design, size, and temperatures, the terminal characteristic is non-linear and the opposite of an equal-percentage-modified- (EQM-) valve characteristic. (EQM valves usually are preferred because they counteract the terminal characteristic.)

- Valve authority

A measure of control-valve performance during operation, valve authority is a ratio between 0 and 1 that indicates how well an automatic-temperature-control valve will perform at a given available differential pressure. Valve authority is calculated as follows:

ß = ΔP control valve fully open and design flow ÷ ΔP control valve fully shut

where:

ß = valve authority

ΔP = differential pressure

A high valve-authority value means differential pressure is close to constant and the relationship between valve capacity and water flow is linear. A low value means differential pressure will increase when the valve closes, resulting in a non-linear relationship between valve capacity and flow. A low valve-authority value will make the circuit-characteristic curve non-linear, resulting in poor control.

Page 3 of 4

In a variable-flow system, the authority of a control valve is variable during operation because the differential pressure across a fully closed control valve depends on piping flows, as well as the opening/closing of other control valves. Therefore, there are two types of valve authority: design and minimum. In determining these values, the numerator in the equation stays constant once the valve capacity is selected. To determine design authority, the denominator becomes the differential pressure available across the circuit at the design condition. To determine minimum authority, the denominator becomes the maximum differential pressure available across the circuit during operation. Both design- and minimum-authority values should be considered when designing a system.

ßdesign = ΔPVdesign ÷ ΔHdesign

ßmin = ΔPVdesign ÷ ΔHmax

where:

ßdesign = design authority

ΔPVdesign = differential pressure across fully open control valve at design flow

ΔHdesign = available differential pressure across circuit at design conditions

ΔHmax = maximum differential pressure across circuit during operation

Valve characteristic and valve authority both depend on control-valve selection. Therefore, the chosen control valve has a great impact on the circuit characteristic and controllability of a system. This means careful control-valve selection is extremely important in maintaining system control. When choosing control valves, consider:

Design flow must be obtained for a control valve to open fully under design conditions.

To facilitate control, the valve characteristic should mirror the terminal characteristic.

To maintain a favorable circuit characteristic, the minimum valve-authority value must not be below 0.25.

To prevent distorting the circuit characteristic too much and keep the curve as linear as possible, the design-authority value for a control valve should be 0.5, and the minimum-authority value should be 0.25.

Besides control-valve selection, other design measures help accomplish this second condition, including avoiding large pipe pressure drops, utilizing variable-speed pumps, and using differential-pressure stabilization valves where needed to create pressure-independent modules.

Key No. 3: Flow compatibility

The third key to hydronic control is creating compatible flows at system interfaces.

Hydraulic interactivity occurs when flow variation in one circuit affects flow in other circuits. In these situations, interactivity problems, such as poor delta-T or freezing in chillers, can arise. To solve these issues, a decoupling bypass between production and distribution usually is installed. However, unless appropriate measures are taken, a bypass can create compatibility problems.

Page 4 of 4

Flow-compatibility problems between production and distribution do not appear under all conditions. At lower loads, everything seems to work fine. However, when peak power is needed during high loads, incompatible flows limit the power that is transmitted from production to distribution.

Flow in production units is well delineated based on manufacturers' published limits. Distribution flow generally is greater than design value because of safety factors and a what-can-the-most-can-the-least approach.

According to an investigation by COSTIC, an HVAC research and training center based in France, distribution flow is greater than 150 percent of the design value in 90 percent of HVAC installations. When distribution pumps are oversized, distribution takes more flow than production can provide. The bypass between production and distribution circuits reverses, creating a mixing point between return and supply flows — the point from which the distribution circuit makes up the missing 50 percent — resulting in higher- or lower-than-expected supply-water temperatures. Even if the secondary pump is not oversized, this situation can happen if the distribution is not properly balanced, in which case an overflow likely will occur at each startup, repeating the problem.

Because the correct supply temperature cannot be reached in this situation, especially at high loads, occupants will complain that rooms are too hot or cold. To fix the problem, pump head is increased, a production unit is added, or the supply-temperature set point is altered. When pump head is increased, flow incompatibility becomes worse and supply-water temperature rises during cooling and lowers during heating. Adding a production unit can solve the incompatibility problem, but can be costly. While changing the set point can compensate for the incompatibility, it can increase energy consumption and, therefore, costs.

The proper solution is to balance production and distribution flows, transferring the correct flow and supply temperatures from production to distribution. This should be repeated at every system interface.

Conclusion

By observing the three keys to hydronic control, hydronic systems can be optimized to deliver specified comfort levels at minimal costs.

Bjarne Andreasen is the senior hydronic training manager for Tour & Andersson. In his 25-year career with the company, he has supported the Danish engineering community in the design of HVAC plants and assisted contractors and commissioning companies in installation, balancing, and troubleshooting large installations. As a member of the TA Hydronic College (www.tahydroniccollege.com) teaching staff, he regularly presents to audiences in Europe, Asia, and North America.