Lunching and Learning: Food for Thought on a Sticky Nightclub Situation

By JEFFREY NEWCOMB, P.E., MBA, LEED AP

William was considering what to have for lunch while waiting for Fred to arrive. William was partial to fish and the tilapia sounded good today. Fred came rushing in, as he often did, and William could tell that he had something interesting related to his work to talk about.

“I have a sticky situation on one of our company’s projects,” Fred said. “Literally, a sticky situation. We did a design for a new nightclub, which was a very successful place, and now the humidity gets so high that the patrons are complaining that they are ‘sticky’. We have also had reports that some insulated ductwork has condensate forming on the outside and sometimes dripping.“

William said, “I believe I have heard of that nightclub. The one down on Fourth Street. They really pack them in there. I heard they got in trouble with the Fire Marshall when the bouncers let too many people in.”

“Yes,” said Fred as he ran his hand through his hair. “More people than we planned on, but we cannot leave it at that. We have to figure out how to solve the problem.”

“Sounds interesting,” answered William. “Have you worked out the causes of the problem?”

Fred nodded, “We had some less experienced staff on this project, both on the design side and the checking side. This led to problems with how the load was calculated and manufacturer’s standard equipment ratings.” Fred continued, “The total loads are pretty close to what they should be, but the balance between sensible and latent loads was way off. That is kind of a general problem in the industry right now. Energy codes have put more insulation in the walls of buildings, which lowers the sensible space loads. They also raise the efficiency requirements on rooftop units. The best efficiency points must be at a high cfm through the units. That leads to a higher percentage of the capacity of the rooftop unit being sensible heat rather than latent heat.”

“Latent heat,“ mused William. “Is that the water in the air?”

“Yes!“ exclaimed Fred. “I think you know more about it than most of the new grads we get. They have never even heard of psychrometrics.”

“Is that a psychology class?” teased William.

“Psy-CHRO-metrics, “ said Fred. “I know you have heard me talk about them before.” As usual in these conversations, Fred started sketching on the back of a paper placemat. This time, he was sketching a psychrometric chart. (Figure 1)

“This kind of a chart was first used by Willis Carrier around 1904 [ref ASHRAE Journal Nov, 2004, pg 16 “Psychrometric Chart Celebrates 100th Anniversary”]. It shows the relationship between the temperature of the air and how much water vapor is in the air. The amount of water the air can hold varies with the temperature of the air in a non-linear fashion. Because it is not easy to calculate directly, we have historically used a chart to see how cooling equipment will match up with the cooling loads in a space. Even though we now have the computing power to figure out relative humidity, dew points, and how many pounds of water there is per pound of dry air at any point, the chart is still a good way of visualizing air conditioning processes.”

“Isn’t all cooling just cooling?” William asked.

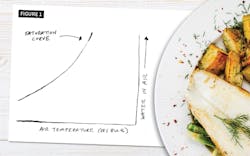

”No,” Fred answered. “The difference between cold and clammy or cool and comfortable has to do with the humidity level in a space. In fact, you could be more comfortable at a higher dry bulb temperature, if the humidity were low enough.” Fred continued, “Dry bulb temperature is across the bottom on the X axis and actual amount of water in the air is measured up on the right hand side on the Y axis. So, on this chart, maximum space conditions are usually about here at 75 dry bulb and 60% relative humidity. We will mark this ‘RA’ for return air. Up here is the usual outside air condition 95 Deg F dry bulb and 42% relative humidity. But in the evening the outside air conditions are closer to 85 Deg F and 58% relative humidity. We will call that ‘OA.’”(Figure 2)

William interrupted “Wait a minute, you went horizontal from the normal outside air conditions to the evening outside air conditions, but you just said the humidity went up even though the actual amount of water in the air did not.”

Fred replied, “The 70% is relative humidity, which is always relative to how much water the air at the dry bulb temperature could hold. As the dry bulb temperature goes down, the same amount of water in the air leads to a higher relative humidity.”

“Strange stuff, air and water”, William commented.

Fred smiled. “That is what makes it so interesting. So, in a typical air-conditioning system, a mixture of that outside air and return air is cooled down below room temperature, which also takes moisture out of the air.” Fred drew a line horizontally to the left to the curve and down the curve until it was below the RA point. “We will call this the supply air point, SA.,” Fred said.

“Why did you go over to the curve before you went down?” asked William. “That seems a roundabout way to get below room temperature.”

“That is how the cooling coil works,” said Fred. “The air is cooled down until the air cannot hold the same amount of water anymore. Then, water has to come out of the air to cool the air more. The sensible cooling done by the coil is related to the distance traveled on the X axis, and the latent cooling is related to the distance traveled on the Y axis. Total cooling (sensible and latent) is related to the length of the straight line between where we started and where we ended.”

William said, “I can see why you like the psych chart if it reduces air-conditioning problems to simple geometry.”

“Well, it does get a little complicated,” Fred admitted. “The amount of sensible and latent cooling done by the cooling coil has to match the amount of sensible and latent cooling needed in the space. That is what we call closing the loop.” Fred drew a line from the SA point to the RA point. “The problem is,” Fred continued, “the ratio of the sensible and latent heat taken out of the air by the coil does not always match the ratio of the sensible and latent heat loads in the space.”

“What happens then?” asked William. “If the coil does not take out enough latent heat, our RA point goes up until the coil does take out enough latent heat. Unfortunately, this leads to a higher relative humidity in the space. That is our stickiness problem.”

“So, the system does not take out enough latent heat,” said William. “Do you need to put a bigger system in?”

“That would not actually solve the problem,” said Fred. “It goes back to how the systems are controlled. A thermostat on the wall turns the cooling in the rooftop unit on and off. That is only a measure of the sensible load in the space and has nothing to do with the latent load.”

“So, if the larger rooftop unit has the same sensible and latent heat cooling ratio —” started William.

“The rooftop cooling just cycles on and off more, and the relative humidity in the space goes even higher,” finished Fred. “Actually, the psychrometric loop always closes, it just does not close where you want it to, sometimes. Two things make controlling humidity more difficult. The first is a problem that we have always had — systems are sized for the worst cooling load the engineer can imagine and hardly, if ever, operate at that load. Our systems are oversized most of the time for the load they actually see. The second problem has developed recently. That one is a result of the energy codes that give us better insulation in our walls and roofs and windows that are also better at keeping solar heat out of our buildings. Since the latent loads in our buildings are not changed by the energy codes, the loads end up with more latent load compared to the sensible loads.”

“Can you adjust the ratio of the sensible and latent cooling power of a coil?” asked William.

“A coil with more rows tends to have more latent capacity, but they also will cool the same cfm to a colder temperature,” Fred answered. “To get a better ratio of latent heat and sensible heat for the same amount of total cooling, the cfm through the coil has to go down so the discharge air is colder. When the air leaving the coil is colder, the air has to travel further down the saturation curve and more water comes out of the air.”

“So, if you want to take more water out of the air and solve your humidity problem, can’t you just make colder air?” William asked.

Fred grimaced. “As with many things, it is not that simple. To make colder air, the amount of air going across the coil needs to drop. One way to look at this is to say that the cfm of airflow per ton of air-conditioning needs to go down. However, manufacturers get skittish when you talk about going below 400 cfm per ton. It is strange, because it really has to do with the heating side of the rooftop unit, not the cooling. When you reduce the airflow, the gas or electric fired part of the rooftop can overheat and cause problems. The lowest I can get a manufacturer to go on a standard rooftop is about 320 cfm per ton. They will allow a much lower cfm per ton if you do not have a heating section. But, we have a heating section, and we need a warranty on the system, so we have to keep the flow through the rooftop unit up.”

William said, “So it sounds like a flow problem. It is a shame you cannot decouple the load from the plant like you did with that campus chilled water system.1 The space needs a low cfm per ton, but the equipment needs a high cfm per ton.”

Fred stared at William with his mouth open. “I have to get back to work right now! Thank you, William! I will tell you all about it later.”

And with that, Fred was gone. William softly shook his head and took a bite of his dessert.

Fred called William a few days later and offered to treat him to lunch at their favorite restaurant.

When they met, Fred was bubbling over. “Remember how you summed up the problem for me last week? You said the space needs a low cfm per ton and the equipment needs a high cfm per ton. That was the key for me.”

“I’m glad I could help,” William replied with a smile, “but I am not sure how that solved the problem.”

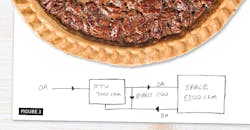

Fred flipped over his placemat to the blank side, and started sketching. (Figure 3). “Here is the rooftop unit and here is the ductwork coming from the unit. Over here is the space with ductwork going to it. The 25 ton rooftop unit needs 7000 cfm to meet the lowest flow the manufacturer wants, but to get the supply air temperature that is needed, the flow needs to be about 5300 cfm. If we bypass 1700 cfm of the supply air into the return duct, we get the colder supply air temperature we need. Also, as the temperature of the air entering the rooftop unit falls, more of the unit’s cooling capacity is directed to latent cooling instead of sensible capacity.

“This helps in two ways. First, the rooftop pulls more water out of the air while the compressors are running. Second, since the sensible capacity has gone down, the compressors have to run longer for the same sensible load. This also leads to more water being pulled out of the air.”

William was a little skeptical. “Is this okay with the manufacturer?”

Fred smiled. “Yes, they have the cfm they need. They even did a new selection at the lower mixed-air temperature and it does not cause any problems. The fix for this problem was cheap and simple. We had the contractor add a flex duct from the supply to the return with a balancing damper. We are all a lot more comfortable now. Thanks for the inspiration again. Since I am buying your lunch today, you might as well get dessert. I hear they have pecan pie.”

1. Jeffrey Newcomb, “Lunching and Learning: A Civil Engineer’s View of a Campus Chilled-Water System”, HPAC (August 2015)

The author has been contemplating unusual HVAC systems as a consulting engineer for over 35 years. He works for IEFM Consulting Engineers in Coal Valley, IL, for which he is responsible for project management and design. Newcomb has degrees from both the University of Illinois and the University of Iowa.