By ANDREW MACALUSO, Product Manager, Lync by Watts

Heat pumps are now a key piece of equipment in water heating systems that address the building decarbonization trend.

Compared to fossil-fueled alternatives, heat pumps typically use electricity, which can be generated from renewable or cleaner energy sources. Also, heat pump technology has proven to be three to five times more efficient under certain conditions than the most efficient alternatives, such as resistance electric heating.

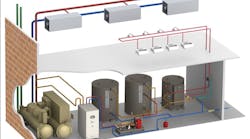

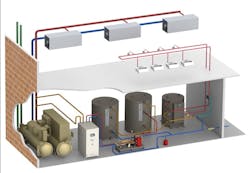

The notion of domestic hot water storage may seem contrary to many current conventional thoughts in terms of modern water heating systems. But there are several heat pump characteristics that make water storage an integral part of an optimized commercial domestic hot water system designed. Four are particularly beneficial:

- Smaller output-to-size ratio: Utilizing storage tanks eliminates the need for multiple heat pumps that would otherwise be needed in instantaneous systems. Footprint advantages are created with this approach, as heat pumps are large relative to their output;

- Longer continuous run time: Heat pumps are not conducive for frequent on-off cycles. The highest operating efficiency is achieved when they run continuously for long durations. Length of operation is limited by the demand, obviously. Storage capacity in the system increases the time the heat pumps are operating to decrease cycling and meet immediate domestic hot water demand;

- “Off-peak” energy usage: The greatest energy cost efficiency is achieved when the heat pump operates during hours with “off-peak” electricity rates. Those timeframes may not align with the peak hours of hot water usage. Storage volume allows properly designed heat pump systems to shift more of the operation to off-peak hours for lower utility costs;

- Equipment cost: Storage tanks are less expensive than adding heat pump units to meet peak domestic hot water demands required for an instantaneous system. The result is lower overall system costs.

Advantages of CO2 Heat Pumps

Engineers and building owners who want to take full advantage of the benefits of storage in a heat pump water heating design should factor in the performance characteristics of the heat pump in consideration.

The limitations of commonly used refrigerants result in a maximum stored water temperature of 140°F under best-case, ambient conditions.

Recently commercialized heat pumps utilize CO2 as a refrigerant to generate water temperatures as high as 180°F. They can do so with drastically lower ambient temperatures at or below 0°F. This makes CO2-based heat pumps suitable as a year-round domestic hot water solution with little to no need for backup heat in most of the U.S.

Elevated Storage Temps for Effective Pathogen Mitigation

Designing for a system with higher output temperatures can reduce the required storage tank capacity by over 25%. As importantly, it assists in the effective mitigation of Legionella bacteria.

While 140°F is adequate as a maintenance temperature for Legionella control, 160°F or higher can achieve a sterilization assurance level capable of killing unusually high amounts of planktonic bacteria in seconds. Storing at elevated temperatures is made simple and safe with integrated digital mixing valves.

Storing water at higher temperatures may significantly impact the life expectancy of the tanks, for lower lifetime costs of the system, as well. Conventional domestic hot water storage tanks are constructed of carbon steel with glass linings to prevent corrosion. These linings and their often-required anode rods are susceptible to corrosion at water temperatures above 160°F. The result is a shortened service life.

Duplex stainless-steel tanks are available that can withstand elevated water temperatures indefinitely, provided the welds are properly designed and the vessel is fully pickle-passivated after fabrication. Storage tank longevity is paramount due to the installation of many heat pump systems on building roofs, where equipment access is limited and replacement costs excessive.

Conclusion

As decarbonization initiatives and legislation begin to spread across North America, the increased use of heat pumps to generate domestic hot water is a growing trend in commercial projects. Maximizing the efficiency and utility of heat pump systems requires special attention be paid to the design and specification of the required storage tanks and the importance of materials of constructions and insulation in those specifications.

##########

An active member of both ASHRAE and ASPE, the author is a product manager for Lync, based in Haverford PA. There, he has led the introduction of many cutting-edge technologies, including the newest commercial heat pump water systems. Macaluso holds a B.S. in Mechanical Engineering from Columbia University, New York City.