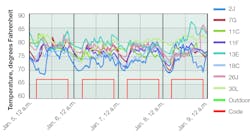

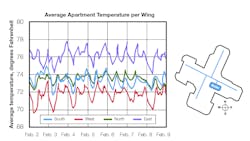

Most older multiunit residential buildings operate with traditional one- or two-pipe steam heating systems. Often, these systems are oversized and difficult to balance, leading tenants to complain their living space is either too hot or too cold, depending on its location in the building and distance from the boiler (figures 1 and 2). When tenants feel too hot, they typically open windows—regardless of the outdoor temperature—in an attempt to regulate the indoor temperature. Others may run their in-window air-conditioning unit, which significantly increases energy use and cost, as they pay to heat and cool their space simultaneously. When tenants report feeling cold, the building supervisor or co-op board may increase the amount of heat being supplied by the boiler, which only inflames the problem, as tenants who originally were “warm,” “too hot,” or feeling “just right” are now even warmer.

Although heat and water can be a building’s largest operating expense, it also can be one of its easiest to control and/or reduce. For multiunit buildings, there are three options:

- Replace the old steam system with a new heating system. This is costly and often involves significant construction activity.

- Install a building-management system or energy-management system. This can help to regulate the amount of heat a steam system produces and lead to significant fuel savings for building owners and/or tenants, but it does not address the heat-imbalance issue associated with centralized control.

- Change from centralized to distributed control of heat. This allows tenants to control the amount of heat their units receive.

Figure 3 illustrates the inadequacy of centralized control.

TRV Theory

One simple and affordable way to achieve distributed control of steam heating is to install thermostatic radiator valves (TRVs). TRVs have been widely adopted in Europe since the 1950s and available in the United States for at least 30 years. Yet awareness and acceptance of TRVs among American consumers, especially in markets with large numbers of steam heating systems, has been limited.

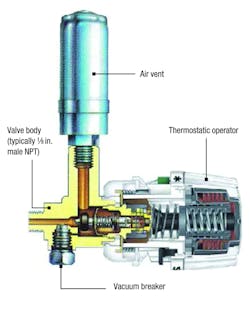

A TRV (Figure 4) regulates the flow of water or steam in a radiator based on the temperature required in a room. It consists of two main components: a valve, which is installed on a radiator, and a thermostat, which typically is installed on the valve or a nearby interior wall. Within the valve, the distance between the valve seat and valve cone determines the amount of water/steam flowing through the valve and into the radiator. The valve cone is operated by the thermostat, which senses changes in room temperature based on a set point determined by the occupant.

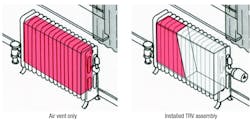

As with many steam heating systems, steam enters the radiator and forces air through a vent. A TRV regulates the air’s ability to escape the radiator based on room temperature and thermostat set point. The radiator, then, is filled with only the amount of steam required to meet the occupant’s desired temperature, which prevents overheating and saves fuel (Figure 5).

TRV Study

With an estimated 83.6 percent of its more than 3.3 million housing units part of a multiunit structure, New York City faces a widespread overheating/energy-waste issue.

In 2010, Danfoss engaged PowerCon Associates LLC, a Manhattan-based consulting engineering firm with an experienced energy-efficiency team, to design and conduct a study addressing overheating in New York City and quantifying potential energy savings with TRVs. The goal was to gather hard data from real buildings supporting the case for broader adoption of TRVs in the United States and providing building managers and co-ops with proof of an acceptable payback period.

PowerCon chose two co-ops on Manhattan’s Upper West Side for the study. Building A was a 36-unit, nine-story building with a one-pipe steam heating system. Building B was a 96-unit, 17-story building with a more complex two-pipe steam heating system.

Installation

Building A. Building A’s system featured 101 radiators. Typically, TRVs for one-pipe systems are easy to install, often requiring only the skills and knowledge of a building manager/supervisor. In Building A, however, some radiators were equipped with metal covers that required a hole to be cut, while other radiators—even those without metal covers—required installation of the temperature sensor on a nearby wall. Despite these issues, the installation was handled by the building supervisor and completed relatively smoothly. In total, 72 TRVs were installed throughout Building A.

Building B. Building B’s system featured 344 radiators, many of which already had been shut off or removed. Installation of a TRV on a two-pipe system typically necessitates the breaking open of the radiator’s steam supply pipe; as a result, the expertise of a plumber often is required. Although Building B’s staff was able to complete the installation without a plumber, it needed to temporarily disconnect several radiators from the piping system to fit everything together. In total, 197 TRVs were installed throughout Building B.

Fuel use: space heat vs. domestic hot water. Ideally, both buildings would have had gas-fired boilers and separate domestic-hot-water (DHW) systems. This would have simplified measurement of fuel consumption and eliminated DHW fuel use from the buildings’ total fuel consumption. As is common in New York City, however, both buildings used oil-fired boilers with integral tankless coils for DHW.

To overcome this challenge, PowerCon installed BTU meters on the DHW systems and instituted a daily logging procedure to track the oil level in the buildings’ storage tanks. This proved only partly successful, as the oil-level meters were less accurate than anticipated. With virtually all energy-savings calculations in multiunit, oil-fired buildings based on oil deliveries, the meter on the oil delivery truck became the default monitoring instrument.

Heating Season 1

By the time the TRVs were installed and operational, only about three months of the heating season remained. Except for the brief period between the installation of the BTU meters and that of the TRVs, no metered “before” data on DHW fuel use were available.

If annual DHW energy use is assumed to be constant, the first heating season yielded promising results. Building A experienced buildingwide annualized total heating energy savings of 4 percent, while Building B realized savings of 9 percent. PowerCon was unable to pinpoint the reason(s) for the difference between the two buildings, but did note an error in boiler operation in Building A that caused the burning of approximately 150 gal. of extra fuel.

It is important to note the TRV installation and test were met with varying degrees of acceptance by the building supervisors/co-ops, which directly impacted on-site activities.

Heating seasons 2 and 3

During the second heating season—October 2011 through May 2012—PowerCon again gathered fuel and tenant-comfort data in Building A. A member of the building’s co-op board made a number of attempts to help his neighbors make the most of their unit’s TRVs.

When the period of January through April 2011 was compared with the period of January through April 2012, no improvement in energy use was seen. However, space heating energy dropped almost 12 percent when the period of January through April 2010 was compared with the period of October 2012 through January 2013.

In addition to reduced fuel use, a qualitative response in regard to improved comfort was seen, particularly among the tenants in Building B. This indicates the TRVs were successful in addressing the buildings’ heat-imbalance issues.

Conclusions and Recommendations

Building setup. The study makes a strong case for metering the oil delivered to a burner. The erratic nature of fuel delivery combined with the difficulty of filling a tank to an exact level each time and several other minor variables makes accurate short-term measurement of consumption and savings challenging.

In residential buildings, fuel is used for space heat and for DHW. Because TRVs have no effect on DHW fuel use, only space-heat fuel use should be considered in oil-use measurements. (DHW consumes an estimated 20 percent of an average building’s fuel.) Thus, it is advisable to conduct studies in buildings with separate DHW systems. The tankless coil systems in buildings A and B made the separation of space-heating fuel and DHW fuel a major challenge.

Another issue in the buildings was uncontrolled heat from uninsulated or poorly insulated risers. Despite the presence of a TRV on a steam-heat radiator, a boiler providing too much heat causes excess heat to pass through risers, which affects room temperature and further impacts occupant comfort and the perceived effectiveness of the TRV. A proper solution is to insulate risers as part of a TRV installation.

The human factor. Human behavior is an important consideration in evaluations of the performance of energy-saving devices. Tenants or customers who have TRVs forced on them or who view the devices’ installation as an imposition or an attempt to take something away from them are less likely to make the best use of the technology. The same can be said of building supervisors and co-op boards. User education is critical to influencing the behavior change required for TRVs to be effective and realizing comfort and energy benefits to the fullest extent possible.

TRVs are easy to install, but also easy to install incorrectly. For example, placement of the temperature sensor is critical to proper set-point management. Also important is the understanding that a TRV cannot directly control underheating. As a result, TRVs must be viewed as part of a greater effort to improve comfort and reduce energy waste.

Split incentives. In the case of many New York City buildings, the landlord pays for the fuel, and the cost is distributed among tenants as part of their monthly rent. This, combined with enticements from local and federal energy-efficiency programs, puts the incentive to install TRVs directly in the pocket of the landlord. The tenant, lacking financial motivation, is less likely to appreciate the efficiency benefit of the technology and may be less inclined to use it properly.

An integrated approach. As a result of the study, PowerCon recommends a truly integrated approach to the installation of TRVs in multiunit residential buildings. Simply installing TRVs will neither produce desired efficiency nor guarantee an impact on heat balance and comfort; additional components may be required to maximize the TRVs’ benefits.

An integrated approach must include adequate up-front tenant and building-supervisor education and communication; follow-up contact to ensure behavior change; a full building analysis to identify any potential system issues, leaks, etc.; and a formal buildingwide protocol for investigating and dealing with tenant comfort complaints.

The Potential of TRVs

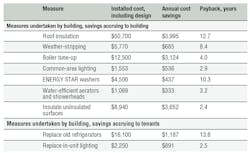

Despite uncontrollable variables in buildings A and B that made TRV testing more difficult than anticipated, PowerCon estimated the payback on the TRV installations would have been about three years. In comparison, the payback on window replacement, which can cost anywhere from $300 to $3,000, is about 15 to 20 years. (See Table 1 for payback estimates for other energy-saving measures.)

It is important to note that replacing windows and doors and installing weather-stripping in overheated units does not remove heat from the units, but, rather, holds heat in and causes the units to become even warmer and more uncomfortable (unless the radiators are controlled to limit the addition of heat). Tenants respond by opening windows or turning on air-conditioning units more frequently and/or for longer periods of time, which prolongs the return on investment for these projects.

PowerCon estimates that had the TRVs been used properly from the beginning of the test period, the energy savings could have been much more significant. In fact, it is estimated that 3 percent of space-heating fuel is saved for every degree room temperature is lowered. Given the estimated number of steam-heated multiunit residential buildings in New York City, this means TRV installation alone could save more than $100 million in fuel costs annually. When TRVs are installed as part of an integrated efficiency program, the savings multiply rapidly.

Bill Boss is a sales manager for Danfoss. With 40 years of experience in the hydronics industry, he is responsible for the sale of hydronic heating and cooling controls and oil-burner components throughout North America.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].