A while back, I designed a HVAC system for a new elementary school in Salt Lake City. It was installed as specified and seemed to be performing just fine. Then, one day, the principal called and said she was feeling cold. It was cold outside (approximately 20°F), but not as cold as the winter design temperature, so the HVAC system should have been able to handle the load.

The system serving the principal’s office was fairly typical: a ducted fan coil above the ceiling with direct-expansion cooling, hot-water heating, minimum outside air only, direct digital controls tied into the building’s main control system, and overhead supply and return—nothing fancy. The office was located on the ground floor, with an east-facing exterior concrete block wall, one small double-paned window in that wall, and a T-bar ceiling with an insulated metal roof above.

I was summoned to the principal’s office (D’oh!). When I arrived, I found the HVAC system performing correctly. I compared the space-temperature reading of the building automation system to that of a calibrated handheld instrument and found them in agreement: 70°F, right on the setpoint. Still, the principal was feeling cold. Maybe she was extra sensitive to temperature. Or feeling sick. Or just plain crazy.

It turned out she was none of those. After some further head-scratching, we measured the surface temperature of the wall adjacent to her desk and found it to be much colder than 70°F. The principal was feeling cold because of the cold surface temperature of the wall. Further investigation revealed the rigid insulation between the exterior concrete block wall and the interior gypsum-board wall that was specified had not been installed. After the insulation was installed, the wall temperature increased, and the principal felt comfortable again. Detention averted.

| Check out this additional resource from HPAC Columnist Larry Clark: Gender and Thermal Comfort |

The situation taught me thermal comfort is more than just dry-bulb air temperature. The 70°F air temperature we measured was not the operative temperature, which is more representative of thermal conditions than just air temperature. The cold wall made the operative temperature much lower than the air temperature.

Operative Temperature and Thermal Comfort

Operative temperature is calculated based on air temperature (dry bulb), mean radiant temperature (MRT), and air velocity. At air velocities below 40 fpm, it is the average of MRT and air temperature. MRT basically is a weighted average of the surface temperatures surrounding an occupant. That is the basic definition; see ANSI/ASHRAE Standard 55, Thermal Environmental Conditions for Human Occupancy, and 2013 ASHRAE Handbook—Fundamentals for more information.

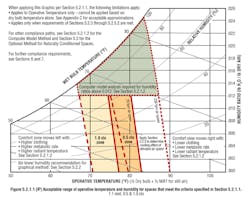

Why should we care about operative temperature? Because the acceptable thermal-comfort ranges shown in ANSI/ASHRAE Standard 55 are based on operative temperature, not dry-bulb air temperature. The thermal-comfort chart for mechanically conditioned spaces shown in ANSI/ASHRAE Standard 55 (Figure 1) may look like a psychrometric chart, but there is one important difference: The x-axis is operative temperature, not air (dry-bulb) temperature. Use that chart with caution, and be sure to read the fine print.

Besides dry-bulb air temperature, MRT, and air velocity, ANSI/ASHRAE Standard 55 addresses three other factors affecting thermal comfort: metabolic rate, clothing insulation, and humidity. When evaluating the level of thermal comfort in a space, consider all six factors—especially if you have occupants who report feeling cold or warm.

Yet Another Reason Not to Like Mondays

Most non-residential buildings are unoccupied at night and on weekends, their HVAC systems off unless setback and setup temperature setpoints are reached. The operators of many of these buildings start the HVAC systems earlier on Monday than other days of the week. They do this because it takes longer to bring the building temperature up (or down) after a weekend of being shut down. But even if space-temperature setpoints are met by the beginning of the occupied period, there still might be comfort complaints. At PECI’s offices in Portland, OR, the operations team receives more comfort complaints on Monday than any other day of the week, even though the occupied space-temperature setpoints are met. The operative temperature may be the reason for this.

After a HVAC system has been shut down for a weekend during winter or when a HVAC system is operated only to maintain setback temperature, a building’s interior surfaces typically will be cold. These include the interior side of exterior walls, floors, ceilings, and furniture. Because surface temperature takes longer to raise than does air temperature (because of the thermal mass related to surfaces), surface temperatures may be low at the start of an occupied period, even with an earlier start of the HVAC system. This could cause uncomfortable conditions for occupants, especially those sitting near exterior walls. The same holds true for high interior surface temperatures during summer: If surface temperatures are much higher than the air temperature, occupants may feel warm, even if the air temperature is on setpoint.

Determining Thermal-Comfort Levels

ASHRAE offers standards, guides, and tools to aid assessment of thermal comfort: ANSI/ASHRAE Standard 55 includes charts and equations that help determine the level of thermal comfort for particular situations, while “Performance Measurement Protocols for Commercial Buildings: Best Practices Guide”1 outlines methods for measuring and evaluating thermal comfort, and Version 2 of ASHRAE Thermal Comfort Tool software calculates a couple of important values related to thermal comfort.

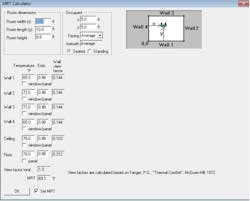

One of the values ASHRAE Thermal Comfort Tool calculates is MRT, factoring the temperatures of surrounding surfaces, the distance between those surfaces and occupants, and the emissivity of the surfaces. Figure 2 shows a snapshot of the tool with some example input values. In this example, the surface temperatures range from 65°F to 72°F, and MRT is calculated at 69.1°F.

ASHRAE Thermal Comfort Tool also can calculate the percent of persons dissatisfied (PPD), the percentage of occupants that would find certain thermal conditions unsatisfactory. It calculates this value based on user inputs for the six main factors affecting occupant comfort. ASHRAE recommends a PPD of less than 10 for acceptable thermal comfort.

Example Scenarios

Following is an example of a thermally comfortable space according to ANSI/ASHRAE Standard 55:

• Air temperature: 70°F.

• MRT: 70°F.

• Humidity ratio: 0.010 lb of water per pound of dry air.

• Air speed: 19.7 fpm.

• Metabolic rate: 1.1 met (e.g., office work).

• Clothing level: 0.90 (typical winter indoor clothing).

FIGURE 5. Unacceptable thermal conditions. Reprinted with permission from ASHRAE.

Now, let’s say it is Monday morning, and the interior surfaces are cold. Lowering the MRT from 70°F to 65°F and keeping the other values the same results in an unacceptable PPD of 16 (Figure 4). Not even raising the air temperature to 73°F results in acceptable conditions (PPD of 11) when the MRT is lowered to 65°F (Figure 5).

When determining the expected level of thermal comfort, you may need to work within the confines of current facility requirements. I have seen owner requirements that include acceptable dry-bulb temperature and humidity, but I have yet to see owner requirements addressing MRT or airspeed in relation to occupant thermal comfort. Also, remember that despite all of the research and literature on thermal comfort and the charts, equations, and tools ASHRAE provides, not all occupants experience thermal conditions the same way.

Measuring Thermal Comfort

How do we measure the six factors affecting thermal comfort?

Metabolic rate and clothing insulation. Evaluation of these factors typically involves observation. What types of tasks are the occupants in a facility or space performing? What types of clothing are the occupants wearing? ANSI/ASHRAE Standard 55 lists metabolic rates for various types of activities and insulation values for various types of clothing.

Air temperature, airspeed, and humidity. Tools for measuring these factors are common in the HVAC industry. Some anemometers can measure all three at once. Check the measurement range, accuracy, and resolution of your instruments to be sure they can be used for a given situation with sufficient precision and accuracy. Also, be sure to keep these tools calibrated so you can have faith in their readings.

MRT. Tools capable of measuring MRT are few and far between—and expensive. In my research, I found a tool that can measure MRT along with many other factors affecting thermal comfort, but it costs more than $9,000! Until cost-effective solutions are developed, here are a couple of ways to determine MRT:

- Insert a temperature sensor into the center of a ping pong ball painted flat grey to make your own globe temperature thermometer. Really. (To learn more, see “Performance Measurement Protocols for Commercial Buildings: Best Practices Guide.”) This will measure operative temperature, not just MRT, and can be used for most indoor environments with low to moderate air movement.

- Measure the temperature of interior surfaces with an infrared thermometer, and use ASHRAE Thermal Comfort Tool to calculate MRT. Infrared thermometers are common in the HVAC industry and relatively cheap.

Summary

When evaluating the thermal comfort of a space, do not focus solely on dry-bulb air temperature; there are other factors—namely, mean radiant temperature, air velocity, clothing insulation, metabolic rate, and humidity—affecting thermal comfort. Measuring those factors and using ANSI/ASHRAE Standard 55 to determine the expected level of thermal comfort in a space is an objective method of determining if there is a thermal-comfort issue or it is just a bad Monday.

Reference

1) ASHRAE. (2012). Performance measurement protocols for commercial buildings: Best practices guide. Atlanta: ASHRAE.

Dave Moser, PE, is a senior engineer for PECI. Focusing on commercial-building energy efficiency, he manages the technical aspects of utility retro-commissioning programs, leads in-building retro-commissioning projects, and conducts research. He can be contacted at [email protected].