According to The National Board of Boiler and Pressure Vessel Inspectors, boiler controls account for the highest percentage of total documented boiler- and pressure-vessel-inspection violations. There are many reasons for this, including neglect, improper maintenance procedures, isolation or elimination of necessary code-required instruments and accessories, and piping modifications. This article will discuss proactive steps plant-level users can take to reduce the risk of violations related to water-level instrumentation, which threaten the safety of both personnel and equipment.

For every power boiler designed to comply with the requirements of Section 1 of the ASME Boiler and Pressure Vessel Code, water-level gauge glasses are required. For boilers operated at pressures up to 400 psi, at least one water gauge glass in continuous service is required. For boilers operated at pressures over 400 psi, one of the following is required:

• Two water gauge glasses in continuous service visible from the control area.

• One water gauge glass combined with two independent level transmitters continuously visible to the operator in the control area. As long as it is kept in working condition, the gauge glass may be isolated, in the event it is needed to verify a level-transmitter reading.

• One gauge glass with transmission of water level to the control area by means of a camera, fiber optics, or mirrors in continuous service combined with a separate level transmitter.

In other words, if one or more water gauge glasses are not continuously visible, two separate level transmitters that are are required. Think about it: If an operator had only one level transmitter to indicate water level, how would he or she know the information being displayed is accurate? If two transmitters are continuously visible, indicate similar levels, and track with each other as water level changes, the operator can have confidence in the information. Thus, proper care and operation of these instruments is paramount for safe boiler operation.

To ensure proper water-gauge-glass function:

• Keep the water gauge glass clean, illuminated, and oriented for easy observation by the operator.

• Perform blowdown as recommended by the instrument manufacturer or plant rules. When conducted properly, the blowdown procedure helps to reduce the risk of sediment buildup in the piping that delivers water from the drum to the indicating glass or instrument.

• Use genuine OEM component parts. The risk of premature leakage increases when components that may not meet OEM specifications are installed in water gauge glasses or level instruments. For example, a neoprene-rubber-type packing ring in a water-gauge isolation valve intended for low-temperature water will not survive high-pressure-steam service.

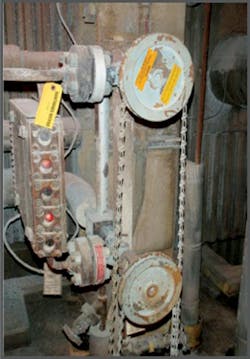

shows a water gauge glass in disrepair, while Photo B shows a code-compliant replacement that vividly displays water level for an operator.

Other level-indicating instruments should be inspected regularly for loose wiring; leaks associated with piping connections, isolation valves, and sensors; and insulation missing from the steam and water piping between the drum and instrumentation. Properly installed piping insulation reduces the risk of burns. It also reduces the negative effects of cooling, which may cause low-level indication because of density differences between the water in the drum and the lower-temperature water in the instrument. Insulation also reduces the formation of excess condensate in steam piping, which has proven to accelerate wear on the internals of instruments and their related connections.

Most level-instrument manufacturers offer detailed maintenance instructions on their Website, which can eliminate guesswork in terms of procedures and frequency. The days of thick vendor catalogs have diminished. Today, most instrumentation technicians and supervisors have online access, which enables them to retrieve the most up-to-date information. As materials improve and instrument technology evolves, it is only logical to contact the manufacturer for the latest technical information or when doubts about servicing arise.

This is just a glimpse of the code requirements for level instrumentation. There are many other factors to consider, including:

• The placement of the indicating range of an instrument relative to the nozzle connections on a drum.

• Boiler-code minimum-pipe-size rules for instrument connecting and drain piping, including pressure limits for various sizes of threaded connections.

• Limitations for the application of certain types of instruments.

• Specifications for pressure part materials for piping, castings, and permissible grades of stainless steel.

• Isolation-valve requirements.

• The placement of level-alarm and low-water-cutout devices.

Plant owners are encouraged to consult with their insurance carrier or safety director to determine the number and type(s) of level instruments required for their plants. The ASME Boiler and Pressure Vessel Code details the minimum requirements. Individual plant specifications, however, often exceed minimum code requirements. Users can prevent violations by exceeding the minimum number of instruments required by code; if one instrument is out of service for maintenance, the plant still may have enough instrumentation in operation to be in compliance.

For more information on this topic, see Section I, “Power Boilers,” and Section VII, “Care of Power Boilers,” of the ASME Boiler and Pressure Vessel Code; ASME CSD 1, Controls and Safety Devices for Automatically Fired Boilers; and “Boiler Inspection Guidelines for Drum Level Instrumentation per Section I of the ASME Code” from Clark-Reliance Corp., available at www.clarkreliance.com/boilerguide/.

James W. Kolbus is manager of boiler-trim products for Clark-Reliance Corp. His responsibilities include product marketing and training and managing a team of application engineers. He is a member of the ABMA board of directors and chairman of the ABMA Associates Members Group.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].