Though they have been around for decades, stack economizers remain limited by boiler design and exhaust and operating-pressure requirements, which confine them to larger and less efficient industrial steam and hot-water boilers.

This article discusses modulating fan-powered economizers, which overcome the challenges faced by traditional economizers and make energy recovery possible for practically any combustion appliance.

Traditional Economizer

A traditional stack economizer consists of a round or cube-shaped housing installed at the outlet of a boiler. Inside, it has one or two rows of tube coils with fins made of copper or stainless steel. As flue gases pass over a medium, heat is transferred to water flowing inside of the coils.

Most boiler designs limit flow resistance on the air side of economizers. Typically, an economizer requires 0.2 in. wc to 0.5 in. wc of draft pressure at the stack outlet (full boiler load) to operate because of its flow resistance. This makes implementing economizers on atmospheric and fan-assisted boilers, which typically require negative draft in the range of -0.02 in. wc to -0.08 in. wc, impractical. As for flow on the water side, the traditional economizer is sized and engineered at constant flow. When a burner has a turndown ratio and a boiler operates at less than full capacity, economizer performance is diminished greatly, as delta-T across the heat exchanger (water side) decreases with the rate of fire. What was designed to be a delta-T of 20°F (water in at 180°F, water out at 200°F) at 100-percent load may become a delta-T of 10°F at 50-percent load and 2°F at 25-percent load, when based on constant water flow.

The typical economizer is limited in terms of applications it can perform with a substantial payback. Modulation on the modern-day boiler can be reasonably high (10:1 turndown rate, or 10 percent at low fire). Also, boiler-plant firing sequences are changing to allow multiple boilers to fire at lower rates of fire. Further, plant sequences are recognizing the benefit of load tracking to keep boilers running, rather than cycling on and off, a practice that virtually eliminates the typical economizer.

Modulating Fan-Powered Economizers

The modulating fan-powered economizer consists of an integrated boiler draft fan and a small-footprint recovery module. A variable-speed fan controls boiler draft. The economizer is designed for high flue-gas temperatures, as well as condensing operation. The module can be of a finned-coil design, like many traditional economizers, or a radiator finned-tube design. In both cases, the coil or tube design is compact and tight. Pressure resistance can be high because the variable-speed draft fan ensures boiler outlet pressures are met and the concentration of coils is overcome. In fact, a radiator-style finned-tube design can be used only when a fan is powering a system.

By incorporating a single-point control that can send and receive a variable signal, a variable-speed pump—typically, fractional horsepower controlled by the temperature of water circulating through the recovery module—can be provided. The controller coordinates airflow based on a pre-set draft set point and controls water flow based on a pre-set temperature set point. The coordination allows for a much tighter and more consistent delta-T, which means load can be shed more reliably and utilized more effectively.

Conceptually, a designer views the application as a complete boiler plant, instead of one economizer per boiler or appliance. A boiler plant consisting of a combination of boiler types, such as forced-draft boilers and atmospheric water heaters, can run through a single modulating demand-controlled economizer.

Performance

Heating boiler. Of the 3,500 to 4,000 hr a heating boiler may operate over the course of a year, only 10 percent to 15 percent may be at 100-percent load; the remaining hours, the load may average only 40 percent to 50 percent.

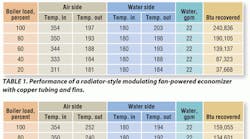

For example, consider five 1,000-MBH Category 1 boilers with barometric dampers. Table 1 shows the performance of radiator-style modulating fan-powered economizers with copper tubing and fins, while Table 2 shows the performance of traditional economizers with copper tubing and fins.

Tables 1 and 2 show that a radiator-style economizer is more efficient from 20- to 100-percent load. At full as well as 60-percent load, British-thermal-unit recovery is more than 50-percent greater with a radiator-style economizer.

Because it is so much more efficient at mid-range load levels, a modulating fan-powered economizer is highly suitable for variable-load systems. A traditional economizer operates with an air-side loss of 0.1 in. wc, which few, if any, Category 1 boilers can handle.

Water-heater boiler. Of the 3,500 to 4,000 hr a water-heater boiler may operate over the course of a year, again, only 10 percent to 15 percent may be at 100-percent load; the remaining hours, the load may average only 30 percent to 50 percent.

Consider the example of five 1,000-MBH Category 1 water-heater boilers with a barometric damper. Table 3 shows the performance of a radiator-style modulating fan-powered economizer with Grade 316 stainless-steel (SS-316) tubing and fins, while Table 4 shows the performance of a traditional economizer with SS-316 tubing and fins.

A radiator-style economizer is more efficient from 20- to 100-percent load. At full load, British-thermal-unit recovery is more than 14-percent greater with a radiator-style economizer, while at 40- to 60-percent load, it is more than 30-percent greater.

A modulating fan-powered economizer condenses when load falls below 50 percent, releasing latent heat. Because there is no recognized standard latent-heat calculation, this potential heat recovery is not recognized here.

Payback

For a heating boiler, annual savings with a radiator-style modulating fan-powered economizer with copper tubing and fins vs. a traditional economizer with copper tubing and fins are estimated as follows:

Annual savings for a hot-water boiler are an estimated 577 MMBH, or $5,482 at a price of $9.50 per million British thermal units per hour.

Multiple-Boiler Applications

With proper draft control, a single modulating fan-powered economizer can be located in a flue serving multiple boilers (Figure 1). This is more cost-effective than an installation of individual economizers that are rendered useless when the boiler they serve is offline or in standby mode.

The integration of proper draft control and high-performance economizers improves the versatility of economizer location. This is especially critical when an economizer is designed to recover latent heat, resulting in a condensing flue from the economizer outward. When properly designed, a condensing economizer can be implemented while retaining some or all of an existing flue system.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].

The president of ENERVEX Inc., Steen Hagensen has more than 25 years of experience in the boiler and venting industry, including more than 10 years as a member of the technical committee of NFPA 54/ANSI Z223.1, National Fuel Gas Code. He has written numerous articles published in industry magazines and frequently speaks to industry groups. Grant Roberts is president of Roberts Mechanical Equipment Co. He has more than 20 years of industry experience, including more than 10 years as a field combustion commissioning technician. Richard Freet, PE, CEM, is manager of VentEnergy. He has 30 years of experience in all facets of boiler- and venting-system design.