Radiant heating systems are being used more often in high-performance designs and green buildings. Many designs now utilize condensing boilers and other high-efficiency technologies, which bring their own sets of challenges. This article will examine tried and true methods of minimizing costly mistakes and maximizing performance. Radiant systems are part of a larger field: Hydronics. Many of the concepts that will be presented in this article apply to hydronic systems in general.

History of Radiant Heating

Radiant heating is smart and safe. It is time-tested: Our nearly 5-billion-year-old sun operates as a radiant mass. An open fire is another everyday example of a radiant heater. Perhaps this is why radiant heat is considered the first form of central heating used by humans. The Romans used it to heat their baths. Radiant heating is the predominant form of heating in Europe and is gaining acceptance in the United States.

- See how one manufacturer incorporated radiant heating into its new Colorado training center.

A survey conducted by the Radiant Panel Association determined there was a 37.4-percent increase in radiant-tubing sales in North America in 2004.1 Radiant systems in the early 1900s used steel and wrought-iron piping embedded in concrete powered by coal-fired boilers. What a difference 100 years makes.

Radiant Comfort

Why is radiant heat so comfortable? Because our bodies are very effective radiators. Roughly 50 percent of a person's heat transfer is through radiation, 30 percent is through convection, and the remaining 20 percent is through evaporation. Comfort also relates to the concept of mean radiant temperature (MRT). MRT is the measure of the combined effects of surface temperatures within a space. MRT is the most important parameter governing human energy balance.

As evidence of the importance of radiant-heat exchange to the body's thermal equilibrium, physiologists have discovered that human skin has extraordinarily high absorptivity and emissivity–more than almost any other known substance, including matte-black metals. Consequently, humans are highly responsive to changes in MRT. In general, for every 1°F that MRT drops, a person must raise air temperature about 1.4°F to achieve similar comfort conditions.

High-Performance Heating System

Not all radiant systems are created alike. An extremely efficient heating appliance connected to an inefficient delivery system does not produce an efficient system. A high-performance heating system is one that maximizes source and system efficiency and minimizes life-cycle cost. It is one that conditions an indoor environment by first reducing the building envelope load, has an energy-performance focus, and includes such important considerations as adding under slab insulation.

Maximizing System Efficiency

Within a radiant system, there are four main points to consider:

- Supply-water temperature.

- Temperature differential.

- Variable-speed pumping.

- Preventive maintenance.

Reducing supply-water temperature generally increases the efficiency of source equipment. Increasing temperature differential also provides an opportunity for increased efficiency. Low-temperature hot-water heating systems historically have been designed for a 20°F temperature drop. There appears to be no logical explanation for this selection, other than that it is easier to size the pump by dividing the British thermal units by 10,000 to obtain pump flow (British thermal units per hour equals 500 multiplied by gallons per minute multiplied by temperature drop). Or perhaps the 20°F temperature drop was selected to protect against flue-gas condensation in non-condensing boilers. Increased differential affords pumping savings, pipe-size reductions, and higher source efficiency through lower return-water temperatures. For example, doubling the differential from 20°F to 40°F halves the required flow rate. Variable-speed pumping does well to improve load tracking and matching building load to system load while also realizing pump electrical savings. Preventive maintenance serves to maintain performance during the life cycle of a system.

Maximizing Source Efficiency

One of the benefits of radiant systems is source flexibility. When considering heating sources, consider solar and waste-heat opportunities first. Geothermal systems also are a good choice, offering coefficients of performance of around 3.5. They may prove to be worthwhile applications, especially if a cooling load also is present. As far as heating sources go, boilers make up the lion's share. Condensing boilers often are a practical choice because they recover additional heat from condensing flue gas, boosting efficiency into the range of 88 to 99 percent. Surprisingly, a condensing boiler is one of the most misapplied elements of modern hydronic systems.

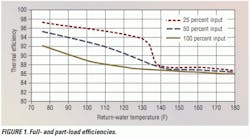

A typical efficiency curve for a condensing boiler is shown in Figure 1. This tells a few things about how to maximize a condensing boiler's operating efficiency. The first thing to note is that unless return water can be provided to a boiler at 130°F or, preferably, well below, a boiler is not realizing its full potential. Second, the efficiency curve shows that a boiler operates significantly better at part load than at full load. A control strategy that exploits the efficiency curve should be applied. So how can 90 percent plus average seasonal efficiency be achieved? By allowing a boiler to condense water vapor in flue gas under operating conditions, modulating boiler input at partial-load conditions to reduce cycling losses, and designing a system to take advantage of boiler and controls technology.

Boiler Piping

Let's look at how a piping system complements high-efficiency operation.

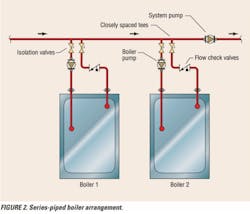

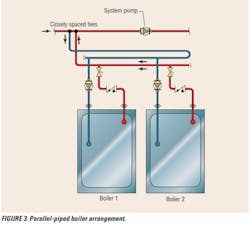

In Figure 2, the series-piped boilers have individual pumps, check valves, and closely spaced boiler tees, all effective elements that prevent unwanted flow through unfired boilers. However, the series arrangement prevents return water from entering each boiler at the lowest temperature.

A more appropriate solution is to pipe the boilers in parallel as shown in Figure 3. The goal with boiler piping is to provide parallel-piped, independent flow.

System Piping

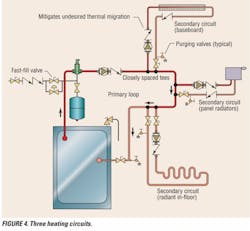

Figure 4 shows three heating circuits, one above the primary heating loop, a second level with the primary loop, and a third below the primary loop. A common misconception is that heat rises. A more correct description is that heat travels to cold areas.

If unchecked, a convective loop will form, which can cause load sources, such as radiators, to become heat emitters when a load does not exist on the system and the respective pump is off.

This phenomenon, known as "thermosiphoning" or "ghost flow," has other undesirable consequences, such as nuisance tripping of pressure and temperature valve.

To remedy this situation, all heat emitters located at or above a primary loop should be protected with flow checks, swing-loaded check valves, or return-side thermal traps to keep the heat where it is wanted.

Supply and return connection tees should be piped as close together as possible (maximum four times the diameter of the primary pipe) to create a near-zero pressure drop between tees. This discourages water from flowing into a circuit during off-cycle operation.

System Controls

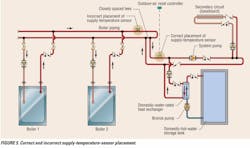

Figure 5 shows a boiler supply sensor improperly located on boiler manifold piping. Boiler pumps normally operate only when a call for heating exists. In this sensor placement, when the boiler-manifold temperature is satisfied, boiler circulators are off, but a load still may exist in the distribution system.

In this case, residual boiler-manifold heat gets trapped and will not get to the distribution system. Also, with an improperly placed sensor, boilers will not fire when heat is needed in the system. A boiler supply sensor should be placed in a position of constant flow to maximize the use of boiler heat into the system and to ensure heat is delivered to a load when required.

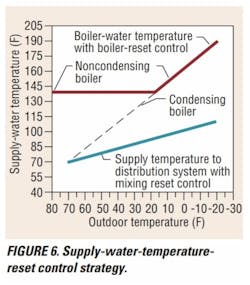

The supply-water-temperature-reset control strategy illustrated in Figure 6 can be applied to primary or secondary heating loops. It goes a long way toward reducing energy consumption and cost. Supply-water-temperature reset also serves to better track building load, resulting in reduced boiler heat loss because of equipment cycling.

High-efficiency condensing boilers typically are most efficient when operating with the coldest return-water temperature possible (Figure 1). When employing supply-water reset, determine the lowest supply temperature that will satisfy minimum boiler-return-water temperature. Non-condensing boilers typically have a minimum return-water temperature to prevent flue-gas condensation and premature failure caused by corrosion.

With multiple-boiler systems, a boiler-sequencing strategy should take advantage of the efficiency profile of the equipment. A condensing modulating boiler typically achieves its highest efficiency at a low part load. Multiple boilers should be controlled to modulate up and down in concert to meet space loads. Boilers also attain their highest efficiencies when running continuously. Boiler sizes should be selected and controlled with this in mind.

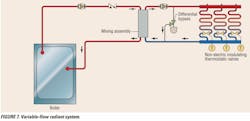

When discussing loads, consideration should be given to on/off vs. modulating control. Variable-flow radiant systems have existed in Europe for decades and are gaining in popularity in the United States.

They involve the use of inexpensive, modulating thermostatic mixing valves, which offer individualized zone control and better system controllability (Figure 7).

These typically are paired with a pressure-actuated bypass valve. Variable-volume, fractional-horsepower circulators with either an integral differential-pressure controller or differential-temperature controller have entered the North American market, offering the additional advantage of pumping energy savings.

These circulators already are in use in Europe. Eventually, they will replace the differential-pressure bypass valves often used today.

Multiple-Load Systems

Radiant-heating systems often are one part of a multiple-load hydronic system, which, for example, may incorporate baseboard convectors operating at 180 F, panel radiators requiring 160°F and radiant tubing peaking at 120°F. Multiple-load hydronic systems offer many benefits, including increased duty cycle yielding higher seasonal efficiency, load diversity, lower installation and system maintenance costs, and reduced space requirements. Guidelines for addressing these systems include:

- Use a single centralized "power plant" to reduce maintenance costs, build in system reliability and redundancy, and downsize the total connected source load required.

- Use multiple boilers when a wide load range exists (high intermittent demand for domestic hot water [DHW]). This will ensure maximum efficiency.

- Employ series primary loops when water-supply temperatures of secondary loads vary. This allows for expanded temperature differentials. Pipe loads require the highest primary-water temperatures at the beginning of a loop. Temperatures decrease as loads travel around the loop, back to the boiler taps (Figure 4).

- Use parallel primary-secondary or "split-primary" piping when the water-supply temperatures of secondary circuits are similar (Figure 5).

- Minimize water temperatures and maximize temperature differential whenever possible.

- Minimize piping heat loss by connecting the indirect DHW tank as parallel circuits.

Domestic Water

Most modern controls operate on a fixed boiler-supply set point for DHW. When a call for DHW exists, boiler supply temperature ramps up to 190°F to recharge the tank. This is fine for applications with a low percentage of domestic-water load and for those in which domestic-water priority is an appropriate boiler-sizing strategy to reduce system cost. For applications with a significant domestic-water load, consider a dedicated boiler, or install a brazed-plate heat exchanger between the boiler and indirect tank to increase heat-exchange surface area, reduce water temperature of the water returning to the boiler, and increase system efficiency (Figure 5).

Radiant systems are an ever-growing element of modern hydronic systems and offer many benefits, including increased thermal comfort and indoor environmental quality, controllability (zoning), energy efficiency, aesthetics, and source-heating flexibility. A high-performance radiant system is one that maximizes thermal and wire-to-water efficiency to satisfy building load over the life cycle of the equipment.

Peter C. D'Antonio, PE, CEM, LEED AP, is the founder and president of PCD Engineering Services, Inc., an award-winning provider of sustainable mechanical/electrical design, energy management, and integrated-building-system solutions. Additionally, he serves as a board member and committee chair for several professional and community organizations, including the USGBC and ASHRAE.

Reference

1) Sweet, J. (2006, Jan. 8). State of the Radiant Industry. Reeves Journal. Retrieved June 26, 2006.