By ZUHAIR IBRAHIM, Ph.D., P.E., and ASIF SHAKEEL, Ph.D., Ibrahim & Associates

Lightning strikes occur during extreme weather conditions and can be the cause of severe damage. In 2021, lightning strikes caused $1.3 billion In U.S. homeowners claim payouts1. In the past two decades, lightning strike research has progressed in both experimental and simulation fields. This has been driven by increased awareness of the risks associated with climate uncertainty and the frequency of extreme events.

This study looked at the effect of direct lightning strikes on pipes and flexible hoses, typically used in building gas plumbing, with special focus on cross-lined polyethylene (PEX) hoses. PEX, a type of flexible plastic, is increasingly being used in construction as a conduit for gas and water transport. It is a material derived from polyethylene (common plastic) through a process involving radiation treatment. PEX tubing made its way into the U.S. market in the 1980s, beginning with its use in radiant floor heating systems, and finding numerous applications thereon.

PEX-AL-PEX tubing goes further and sandwiches a layer or aluminum between two layers of PEX (Fig. 1), increasing the sturdiness and resilience of the tube. Among the PEX tubing, PEX-AL-PEX has the highest-pressure rating, and through a memory feature, the ability to retain its shape.

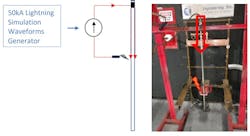

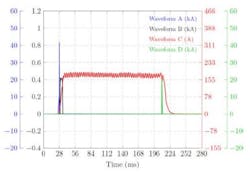

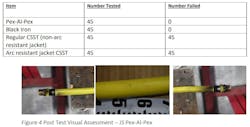

Our study used a random, 45 to 50 samples from two types of corrugated stainless steel tubing (CSST) pipes -- regular CSST (non-arc resistant jacket) and Arc-resistant jacket CSST; black iron pipes, and Pex-Al-Pex pipes. Each sample was tested using the setup shown using the below schematic for the test setup. These tests were conducted at the DNB Laboratories, Fullerton, CA. The current enters the sample at one end and exits to a ground point located 1/8-inch from the sample. The simulated lightning occurs near the ground metal bar, with the potential damage accompanying it.

Following the lightning test, each sample which did not exhibit a clear failure (hole), was subjected to a pressurized leak test using compressed air. Black iron pipes, and Pex-Al-Pex hoses were tested at 60 psi. The CSST hoses (regular and arc resistant jacket) were tested to 25 psi which was their maximum rating. The test duration was 10 minutes in accordance with the guidelines of NFPA 546 . At the conclusion of the tests, the following results were recorded:

Conclusion

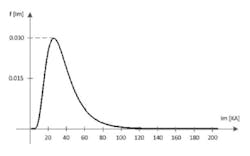

The report presents the results and findings from an extensive experimental lightning strike study of common piping and CSST used by the gas industry. The high current value chosen as 50kA, which is 60% higher than the mean value of a direct lightning strike. The study examined the response and damage to two common CSST types, and black iron pipe. The results were analyzed using pairwise using hypothesis test of two sample proportions at a significance of 0.05. The statical tests confirm that Pex-Al-Pex hoses have a failure rate which is significantly lower than comparable CSSTs. Pex-Al-Pex hoses had a pass rate similar to those of black iron pipes. Pex-Al-Pex hoses were found to withstand up to 50 kA without exhibiting noticeable damage and were capable of holding pressure at 60 psi.

The hypothesis Test for Two-Sample Proportions was conducted pairwise among the listed pipes, to statistically compare the above test results (Appendix A), at the standard significance level of 0.05 (95% confidence level). It shows that the Pex-Al-Pex and Black Iron pipe are not distinguishable, while, with at least 95% confidence, both Pex-Al-Pex and Black Iron pipe in general would have failure rates significantly lower than the CSST pipes, hence a higher resilience to direct lightning strikes, as far as the test conditions and samples are representative of the true conditions and populations, respectively.

#####

1 Insurance Information Institute - https://www.iii.org/press-release/triple-i-lightning-caused-13-billion-in-ushomeowners-claim-payouts-in-2021-supply-chain-issues-exacerbate-losses-062122 ;

2 D.W. Clifford, K. E. Crouch and E. H. Schulte, "Lightning Simulation and Testing," in IEEE Transactions on Electromagnetic Compatibility, vol. EMC-24, no. 2, pp. 209-224, May 1982, doi: 10.1109/TEMC.1982.304032;

3 K. Berger, R.B. Anderson, H. Kröninger, Parameters of Lightning Flashes,” Electra, No. 41, 1975 23–37;

4 P. Venturino et al. “Pipeline failures due to lightning”, Engineering Failure Analysis 64 (2016) 1–12;

5 Sun J, Yao X, Tian X, Chen J, Wu Y. Damage characteristics of CFRP Laminates subjected to multiple lightning current strike. Appl Compos Mater 2018;26:745–62;

6 NFPA 54-2021 8.1.4 and 8.1.4.3.

Acknowledgment

This research was supported by Ferguson Enterprises, LLC. The experiments and the analysis were independently conducted, and the authors have no financial interest in any commercial tubing used in the study.