Case Study by Daikin Applied

Medical issues are stressful enough without adding overheating to the mix. Keeping patients, staff, and visitors as comfortable as possible is a top priority for any medical center. It’s no surprise then, that when Southern New Hampshire Medical Center (SNHMC) in Nashua started having problems with its antiquated chiller system, the facility was eager to make an upgrade.

“They serve the entire building, including operating rooms and patient rooms and general use in the building,” said Alex Finlayson, field supervisor of manufacturer Daikin Applied’s Boston Service office, explaining the glaring need for new equipment. “They had three non-Daikin centrifugal chillers that were 25 years old, that had leaks and control platform issues. The platform wouldn’t support it anymore, so the customer started to look at options to replace the machine.”

Located in Nashua NH, the 188-bed Southern New Hampshire Medical Center was already undergoing several renovation projects when it decided to replace the chillers, too.

Homework, Solution

Finlayson gives credit to a diligent administrator for making the right call. “The facility director did his homework. He compared the competitor’s machines they already had and similar replacements with what (we) had to offer. The energy efficiency of the chiller he selected was significantly better.”

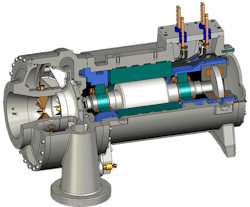

“It was mainly energy-based,” Finlayson explained. “That was the reason for investing in these chillers. That and a magnetic bearing chiller is certainly a cutting-edge piece of equipment. We got involved and introduced them to our WME magnetic bearing compressor, which improved efficiency and decreased costs.”

(Photo courtesy of Engelberth Construction)

Daikin’s Magnitude® chillers can, in fact, save building owners up to $4 million over the life of the chiller. With installations all over the world, the oil-free design may reap up to 40% efficiency gains and reduce maintenance costs by eliminating the oil, mechanical seals, wear surfaces, and gears.

Despite the clear decision, the team faced obstacles in the path to installation. Removing three aging chillers from a hospital basement wasn’t a simple task. Fortunately, the chiller project was scheduled alongside several other renovations, including new lighting and a new pump system, which helped make the Daikin project less obtrusive.

A single Magnitude WME chiller can save building owners up to $4 million over the life of the chiller.

Even so, Finlayson said it was still a major undertaking. “It was a very complicated rig to get the old chillers out and the new chillers in.” To fit into the basement space, the chillers had to be disassembled, dropped through a pit to the mechanical room level, reassembled and installed.

“It was very time-consuming,” said Finlayson. “Long days, 12-hour days to get the new machines down into the basement and the old ones out. It was a year-long project, one chiller at a time.” Still the project came in on time and under budget, he noted.

The magnetic bearing technology eliminates oil, bearing wear surfaces, and gears for longer machine life and increased reliability. The design eliminates the risk of contamination from efficiency-robbing oil buildup onto heat-transfer surfaces.

“The Medical Center is very happy with the products, services, and advice we have received to date,” said Scott Lever, SNHMC Mechanical and Utility Systems Manager, Facilities Engineering Dept.

Facility as it appeared in 1925.

Positive Outcome

The long-running labor effort paid off. In the two years since the project was completed, the facility has seen improved energy efficiency and a significant drop in mechanical issues. Finlayson said the facility director has been pleased. “The maintenance costs were substantially less as well because the chiller uses a magnetic bearing compressor and he didn’t have to deal with changing oil every year.”

It may have been a long process getting the chiller system upgraded, but now the staff at SNHMC can be assured that they are delivering superior indoor air quality (IAQ) for the best patient outcomes. That’s an upgrade that every hospital visitor should be able to appreciate.