Built in 1965 to serve 500 K-6 students, Hatfield Elementary in Hatfield, Pa., part of the North Penn School District, was, by 2014, facing challenges familiar to many schools: Spaces were ill-suited for modern teaching strategies, and the mechanical, electrical, and plumbing systems were becoming obsolete. In the HVAC system, radiant ceiling panels were leaking and dripping water because of condensation.

The North Penn community supported the closing of the school for 16 months for a major renovation, including the addition of a new entry/administration wing and the replacement of the entire HVAC system.

The district’s construction manager, Don Schild, called upon a trusted team that included Eddystone, Pa.-based architectural engineering firm Bonnett Associates Inc. and Telford, Pa.-based contractor Myco Mechanical Inc. to design and supply the new HVAC system.

For a district firmly committed to energy efficiency, the key question facing the team was, “What type of HVAC system and, particularly, which energy-recovery technology will best meet the needs of students and the district?” Walter J. Subers, PE, of Bonnett Associates said. “We looked at energy recovery, economics, and maintenance.”

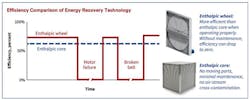

Subers had designed and specified units with energy-recovery wheels, but was seeking a technology requiring less servicing, as the school district maintains more than 20 buildings.

Subers learned of enthalpic-core technology through a seminar sponsored by Jamison, Pa.-based manufacturers’ representative Chase & Associates Inc. An enthalpic energy-recovery core transfers sensible and latent energy between exhaust air and fresh air, reducing the amount of energy needed for heating or cooling.

The district’s experience with energy-recovery wheels was that, though highly efficient, they require an ongoing time commitment for cleaning, maintenance, and repair.

“Maintenance is money,” Schild said.

When Schild asked if there was something else that would reduce maintenance and still allow energy recovery, Subers had an answer.

The Solution

The design team agreed on a HVAC system featuring Valent’s VPRC packaged energy-recovery ventilator, which uses a dPoint Technologies enthalpic energy-recovery core.

For Subers, VPRC core technology represents an optimal trade-off: Though it may be slightly less efficient than a wheel, it has much lower maintenance requirements. It was important to the team that the enthalpic core complies with ANSI/ASHRAE/IES 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings, and that, with no moving parts, the enthalpic core can be more efficient overall than an energy wheel (Figure 1).

At Hatfield Elementary, six Valent units provide neutral ventilation air to rooms with fan coils. Meanwhile, three Valent rooftop units provide comfort cooling for the administration area, gymnasium, cafeteria, and library. All units can supply 100 percent outdoor air during occupied hours using a control sequence that modulates based on space carbon-dioxide levels. The units are off during unoccupied hours to further save energy. Additionally, they connect to the district’s central building automation system for remote monitoring and control.

Subers calls VPRC a “user-friendly machine.” Rich Chase of Chase & Associates likes that the dedicated outdoor-air system (DOAS) with enthalpic core is particularly well-suited for school applications.

“Unlike some types of building portfolios,” Chase said, “school districts keep their buildings a long time. So, looking at the total cost of ownership and factoring in both energy efficiency and maintenance can be extremely beneficial for long-term occupants.”

Results

Hatfield Elementary Principal Deana Waters said the old HVAC system left many spaces too hot or too cold. She credits the new system with creating a more comfortable learning environment, one in which it is “easier for kids to stay engaged.” She has received positive feedback from staff members and no longer sees fans being used to cool inner rooms.

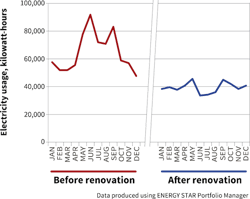

The updated HVAC system achieved an ENERGY STAR rating of 96 (out of 100) and received three Green Globes through the Green Building Initiative program, which recognizes application of energy, water, and environmental-efficiency best practices.

From a construction-management standpoint, Schild calls Hatfield Elementary “the best project I’ve done.” He credits Bonnett Associates, Myco Mechanical, Chase & Associates, and Valent with “making my job easier” and says their good communication made for “a very pleasant project.”

Valent Air Management Systems is a business of Unison Comfort Technologies.

For Design Solutions author guidelines, call Scott Arnold, executive editor, at 216-931-9980, or write to him at [email protected].