PART ONE: By JOE ROCKHOLD, Louver Product Manager, Ruskin

PART TWO: By JAMES LIVINGSTON, Applications Manager, Ruskin

[ PART ONE ]

The 2020 Atlantic hurricane season was the most active on record, generating 30 named storms – 12 of which made landfall. As climate change continues escalating both the number and intensity of dangerous storms, protecting people and property in these vulnerable areas is now mission critical.

HVAC louvers, which are used to provide fresh airflow in a facility, can sometimes allow wind-driven rain into buildings during severe storm events, causing significant damage to the structure and equipment. There are two louver test standards developed to test for these high-velocity wind-driven rain events – TAS-100A and AMCA 550.

TAS-100A is the original Miami-Dade (Florida Building Code) test standard developed in the 1990s after Hurricane Andrew caused widespread destruction in that area. TAS-100A was the original test method that set the standard louvers needed to meet to be considered resistant to high wind and wind-driven rainfall. AMCA 550 is the latest testing standard for hurricane louvers. This article provides an overview of these standards and compares the testing efficacy of both.

Property-protecting louvers

Hurricane louvers are required to meet very stringent performance requirements, more so than regular louvers. Facilities along the eastern seaboard and Gulf Coast regions are required by International Building Code to install severe weather-resistant louvers in locations that require fresh-air intake or exhaust of carbon-dioxide-contaminated air. Hurricane louvers are specifically designed to resist the intake of excessive amounts of rainfall and debris carried by hurricane-force winds. Each hurricane louver is tested to specific standards and must be approved for use in a hurricane zone.

Testing standards for TAS-100A

The Miami-Dade Building Code of Compliance Office (BCCO) requires louvers installed "in a location where the room behind the louver is not designed to drain water penetrating into the room, or the room will house non-water-resistant equipment, components, or supplies" be tested in accordance with TAS-100A.

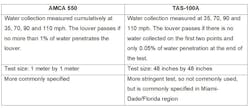

The TAS-100A standard uses a 48-inch-by-48-inch sample. Performance is tested against a rainfall rate of 8.8-inches per hour with wind gusts that are tested at a set number of minutes. The 35 mph, 70 mph and 90 mph tests are run for 15 minutes and the 110-mph test runs for five minutes.

After each test point, water that has passed through the louver is collected and weighed. To meet the more stringent TAS-100A standards, only 0.05% of the total water sprayed at it can pass through the louver, while at the first two set points of 35 mph and 70 mph, no water is allowed.

Testing standards for AMCA 550

The AMCA Standard 550 Test Method for High Velocity Wind Driven Rain Resistant Louvers has a similar test method as TAS-100A, but varies in water collection requirements, which make it more commonly specified.

AMCA 550 uses a 1-meter-by-1-meter sized sample to measure water damage impact. However, during the calibration of the test and measuring equipment, AMCA 550 requires collection of water at a different reference location. Similar to TAS-100A, the sample louver is mounted into a makeshift wall with a collection chamber inside the opening and an open top to allow a consistent air stream. The chamber’s walls are lined with plastic or similar smooth surface to funnel any penetrating water into a collection device for measurement.

During the test, water is injected into an air stream and directed at the sample louver. The test measurements are conducted at the same wind speeds as TAS-100A – which are 35 mph, 70 mph, 90 mph and 110 mph – as well as at the constant flow of 8.8 inches of rainfall per hour.

While both standards are widely accepted by authorities having jurisdiction (AHJ) in hurricane-prone regions, Miami-Dade has recognized AMCA 550 as an equivalent to their own TAS-100A test standard.

Although both are often perceived as interchangeable, three key differences are highlighted below:

Features of hurricane-compliant louvers

Most high-velocity wind-driven rain louvers have tight blade spacing with vertical orientations. The vertical blades use gravity to quickly drain the rain and reduce the risk of water puddles forming and blowing through the louver.

The industry does offer horizontal-bladed operable louvers, but they must be closed during a storm event to meet AMCA 550 requirements and must remain in the closed position until the storm subsides. Other products offer a combination of two louvers – typically a horizontal-bladed front louver and vertical-rear bladed louver.

Finally, there is a louver and damper combination. With this combination, the damper must be closed during a severe weather event to satisfy AMCA 550. However, both the operable louver and louver/damper combination are not permissible in essential facilities – such as hospitals, fire and police stations – which must remain open during a weather emergency.

Both the Miami-Dade Notice of Acceptance (NOA) and Florida Building Code (FBC) websites offer complete listings of louvers that have been tested and approved to TAS-100A or AMCA 550 standards. Contractors can also review the louver product submittal sheet to confirm proper specification. Selecting the right louver, the first time will ensure approval from the authority having jurisdiction (AHJ) while helping protect buildings and occupants during an ever-expanding hurricane season.

#########

[ PART TWO ]

The 2012 edition of the International Building & Mechanical Codes (IBC & IMC) introduced new testing requirements for air intake and exhaust louvers located in hurricane-prone regions of the United States. Louvers installed in Florida were already subject to the testing standards of the Florida Building Code (FBC).

For years, a Miami-Dade Notice of Acceptance (NOA) was considered the standard certification for hurricane louvers installed anywhere simply because there were no other standards that were widely used by louver manufacturers. However, Miami-Dade NOA’s are not required by code outside of Florida and NOA louvers are typically designed for much higher wind load pressures than what’s found in areas outside of South Florida. Several years ago, Air Movement and Control Association International, Inc. (AMCA) created ANSI/AMCA Standard 540, Test Method for Louvers Impacted by Wind Borne Debris, and ANSI/AMCA Standard 550, Test Method for High Velocity Wind Driven Rain Resistant Louvers.

These standards were adopted as requirements in hurricane areas in the 2012 IBC & IMC and have remained in all successive editions of the codes. The AMCA standards provide a more streamlined means of qualifying louvers for hurricane conditions outside of South Florida. However, designers are often challenged with determining which standards apply to their projects considering their location, building type and local code amendments. There are also multiple styles of louvers available that meet these standards, each with their own characteristics that should be considered when selecting. In this paper, we examine the code requirements and outline the styles of compliant louvers available.

Hurricane Louver Test Requirements, 2012 to Present

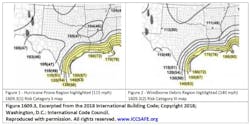

Louvers protecting air intake and exhaust openings in projects located in Hurricane Prone Regions are required to meet ANSI/AMCA Standard 550, Test Method for High Velocity Wind Driven Rain Resistant Louvers, per Chapters 4 & 5 of the IMC. Hurricane Prone Regions are defined as:

- Areas in the U.S. Atlantic Ocean and Gulf of Mexico coasts where the ultimate design wind speed for Risk Category II buildings is greater than 115 mph;

- Hawaii, Puerto Rico, Guam, Virgin Islands and American Samoa.

For projects located in Windborne Debris Regions, louvers protecting air intake and exhaust ventilation ducts not assumed to be open that are within 30 feet of grade are required to meet ANSI/AMCA Standard 540, Test Method for Louvers Impacted by Wind Borne Debris, per Chapter 16 of the IBC. Windborne Debris Regions are defined as:

- 1 mile from coastal mean high-water line where the basic design wind speed is 130 mph or greater, or in areas where the basic design wind speed is 140 mph or greater.

The Ultimate Design Wind Speed Maps found in Chapter 16 of the IBC can be referenced to locate these regions (see below).

Per the IBC definitions and maps, AMCA 550 wind driven rain resistance is required further inland than AMCA 540 impact resistance. Texas cities that are affected by one or both of these requirements include Beaumont, Houston, Victoria, Corpus Christi and McAllen. Designers working on projects in these and other areas close to the coast should consider the requirements of the governing building codes when selecting louvers.

Special Code & Amendment Adoptions

Some areas vary from the general International Code Council (ICC) requirements. For example, the City of Houston, Texas, has adopted an amended version of the 2012 IBC which elevates the ultimate design wind speed for Risk Category III & IV buildings to 150 mph. These building categories include important facilities such as hospitals, police & fire stations, emergency response centers, buildings with large occupancies and various other structures. The 150 mph wind speed qualifies those buildings to be in the Windborne Debris Region and requires them to use AMCA 540 Impact Resistant intake & exhaust louvers within 30 feet of grade. In addition, Houston follows the 2012 Unified Mechanical Code (UMC) which states that on any building, the Authority Having Jurisdiction (AHJ) can request AMCA 540 impact resistance for louvers within 30’ of grade. The 2012 UMC also prescribes the use of AMCA 550 compliant louvers for intake & exhaust applications within the Hurricane Prone Region, which the city is located within. Other municipalities close to Houston require AMCA 550 and potentially AMCA 540 depending on the ultimate design wind speed of their area per the ICC codes.

AMCA 540 & 550 Test Variations

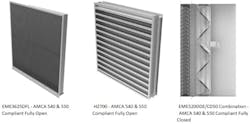

Both AMCA 540 and 550 are pass/fail tests and manufacturers must successfully test their products to be considered compliant. AMCA offers a Louver Listing Program to manufacturers which confirms compliance to the standards as well as a Listed Product Search tool on AMCA.org. The tool is a great resource to designers looking for compliant models to use in their designs. Note that louvers may be qualified for either or both tests, and there are variations within the tests themselves. For example, the 540 Impact test has two impact levels: Level D Basic Protection for standard buildings, and Level E Enhanced Protection for essential buildings such as hospitals and emergency response facilities. AMCA 540 also has a cyclic wind pressure option which is suggested for louvers used in the High

Velocity Hurricane Zone in South Florida. AMCA 550 has two classifications: Blades Fully Open and Blades Fully Closed. Louvers qualified with Blades Fully Open have passed the test with open blades and allows ventilation at all times. Louvers with Blades Fully Closed must be shut to pass the test and do not allow ventilation in that setting.

Available Louver Styles

AMCA 540 Impact Resistance – While a very challenging test, there are multiple designs that pass AMCA 540. This gives designers a variety of louvers to select from, including traditional drainable blade-style models and wind driven rain louvers that feature either horizontal or vertical blades. Typically louvers that are rated only for impact resistance are open & do not require closed blades to pass the test.

AMCA 550 High Velocity Wind Driven Rain Resistance – This test is more difficult to pass resulting in fewer choices for designers. For louvers with blades fully open, horizontal blades only without additional vertical blades generally do not pass AMCA 550. Open louvers typically utilize vertical blades, either by themselves or in combination with horizontal front louvers to hide the vertical blades behind. Louvers with blades fully closed can be operable, or can consist of an open louver combined with a qualified low leak control damper in a common sleeve. Either way, the operating blades must be closed to pass AMCA 550. Note that using a wind driven rain resistant louver in a louver/damper combination will provide better rain protection than a traditional drainable louver when the damper is open.

Note that there are significant considerations when using a louver and damper combination to meet AMCA 550:

- No ventilation when blades are fully closed. If the building is occupied, it must be ventilated with outside air per ASHRAE Standard 62.1 Ventilation for Acceptable Indoor Air Quality;

- Louver/damper combinations are significantly more expensive than a single open louver;

- Dampers must be specific low-leak models that have been qualified for use. Non-qualified standard control dampers do not comply;

- Actuation is required to close dampers. If electric actuators are utilized, power must be run to the actuators and a control strategy should be devised for their operation.

Many wind-driven rain models with open vertical blades meet both AMCA test standards making them the most cost effective style to use. However, if vertical blades are not desired aesthetically then louvers with horizontal front and vertical rear blades are available to provide a traditional louver appearance. While fully closed louver/damper combinations can also meet both standards, they should only be considered for buildings that will not be occupied during a hurricane and must be carefully designed and specified to minimize issues during the construction process.

Recommendations

- Review the louver requirements per code where your project is located & determine what test standards are prescribed. Be sure to consider any local amendments & special code adoptions;

- Determine what louver characteristics are needed for the project: Do you need a louver that is fully open allowing ventilation? Are vertical blades aesthetically acceptable? If using a louver/damper combo, use a wind driven rain resistant louver to reduce water penetration when the damper is open;

- Use the Listed Product Search on AMCA.org to find qualified louvers.

#########

About the authors

Based in Grandview MO, Rockhold is now in his 22nd year at Ruskin, where he once served as testing supervisor in the firm's research and development lab. Based in Kansas City MO, Livingston is now in his 33rd year at Ruskin, where he boasts extensive experience in product development, product management, sales management, and customer service.