Commercial-building-owner sentiment regarding ground-source-heat-pump (GSHP) systems ranges from, "They are the only system we want in our buildings," to, "We will never do one of those again." Installation costs can range from $12 per square foot to more than $50 per square foot, while operating costs and occupant comfort also can vary across the spectrum. However, successful applications can be found in a wide variety of climates and building types. In the initial data set of the New Buildings Institute's "Getting to Fifty" database of buildings that consume at least 50-percent less energy than code-compliant buildings (www.newbuildings.org/gtf/index.htm), 20 percent of the buildings listed were served by GSHPs, even though GSHPs' market penetration is less than 1 percent.

This article discusses how the cost premium of closed-loop (ground-coupled) heat pumps can be minimized--and energy use reduced, reliability improved, and comfort enhanced, compared with more complex, controls-intensive systems--by simplifying in-ground piping and above-ground HVAC systems.

Design Philosophy

Often, project schedules and fee structures dictate that a third-party non-engineer (ground-loop contractor, pipe vendor, etc.) design a ground loop, with an engineer designing the balance of the system using conventional HVAC practices. The result can be a system with high energy consumption linked to an expensive ground loop that does not adequately transfer and diffuse heat.

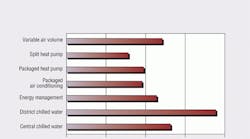

The design of reliable, cost-effective, energy-efficient GSHPs requires a system approach, as well as a willingness to depart from conventional HVAC wisdom. While it commonly is believed that central systems enhanced with energy-saving subsystems, such as variable-air-volume (VAV) and energy-management systems, use less energy than simple unitary equipment, measured data indicate otherwise (Figure 1).1 GSHPs present the possibility of enhancing the low-energy-consumption characteristics of unitary heat pumps in buildings typically served by central systems. A challenge is minimizing the fan/pump energy consumption and controls complexity plaguing central-air and water-distribution systems.

Ground Heat Exchangers

Because of lower land-area requirements (about 150 to 400 sq ft per ton), ground heat exchangers most commonly are arranged vertically. Increasingly, however, horizontally bored loops are being applied because multiple stacked loops are able to be placed at greater depths (typically, 15 ft, 30 ft, and 45 ft), provided there are no rocks and/or boulders.

Vertical loops typically are characterized by:

- Vertical bores 4 to 6 in. in diameter and up to 600 ft (200 to 300 ft being typical) in depth separated by 20 to 30 ft.

- A thermally fused high-density-polyethylene (HDPE) U-tube 1 in. in diameter for bores to 300 ft, 11/4 in. in diameter for bores to 500 ft, and 11/2 in. in diameter for bores to greater depths.

- Grout or fill injected into the cavity between the U-tube and bore wall to promote heat exchange and prevent water migration from the

surface and between aquifers. Thermally enhanced grouts are common because they typically reduce loop lengths 15 to 35 percent, compared with conventional grouts.2,3

Claims of substantial reductions in heat-exchanger length should be viewed with skepticism because 70 to 80 percent of resistance to heat flow

is attributable to the ground itself.

The additional cost ($5,000 to $10,000) of installing a vertical ground loop and performing a thermal-properties test prior to system design often is warranted, as:

- Loop design can be optimized using field data, as opposed to worst-case values.

- The degree of drilling difficulty can be determined so that loop contractors do not have to assume worst-case conditions when submitting bids.

- The test loop can be used as a permanent ground heat exchanger. For smaller projects, thermal properties can be conservatively estimated using information from the Geo-Heat Center (http://geoheat.oit.edu/techpap.htm#hydro) and state surveys, as vertical-loop costs for exterior components typically are $1,500 to $2,500 per ton. This does not include interior-piping costs, which vary depending on loop type.

Loop Types

Unitary. The recommended first alternative for GSHPs is the simplest unitary-loop design, one with a single heat pump, a circulator pump that is cycled with the compressor, and a single ground loop made entirely of HDPE (Figure 2). This type of loop:

- Is easy to control.

- Usually is least expensive because header costs are minimal.

- Can be installed and serviced by technicians with modest hourly rates.

- Is best for one- and two-story buildings.

- Is best with moderate- to low-load-diversity buildings because the advantages of load diversity are not utilized.

- Does not require corrosion inhibitors, which may be regulated for in-ground applications.

Subcentral. For buildings that do not easily lend themselves to unitary loops, a subcentral loop (Figure 3) is suggested. In many cases, load diversity can be exploited without the entire building being connected. For example, a classroom wing with east-exposure rooms can be linked with heat pumps in west-exposure rooms. Another example is a cafeteria with a noon peak load linked with a gymnasium with an evening peak load. A sizable portion of the water-heating load in the latter example could be met with water-heating heat pumps connected to the loop that cools the kitchen.

Subcentral loops:

- Are easy to control.

- Are relatively inexpensive because the cost of large-diameter in-ground headers, ground vaults, and large interior piping can be avoided.

- Can be installed and serviced by technicians with modest hourly rates.

- Can be used with larger buildings.

- Can realize a significant portion of building-load-diversity advantages.

- Can be looped with 100-percent-HDPE piping, which does not require corrosion inhibitors, which may be regulated for in-ground applications.

Central. For buildings that do not easily lend themselves to unitary or subcentral loops, a central loop (Figure 4) is suggested. Although often the most expensive (larger and more extensive in-ground and interior piping headers, valve vaults, central control, and added pump capacity),4 usually the least efficient (because of higher pump power), and requiring the highest-fee service personnel, this type of loop has its advantages:

Heat Pumps, Outside Air, and Controls

The equipment most commonly used in GSHP applications is the extended-range water-to-air heat pump, which encompasses vertical up-flow and down-flow, horizontal, classroom, and console units. Water-to-air units offer the greatest potential for extremely high efficiency because direct-air room-to-refrigerant coils have the smallest temperature differential between condenser and evaporator. To take advantage of this, minimizing fan and pump power and limiting ground-loop-temperature rise (in cooling) and decline (in heating) is critical.

With water-to-water heat pumps, efficiency can be quite high if the ground-loop-to-building loop-temperature difference is small, fan power is minimized, and building-loop pumps are sized and controlled properly. An example of a high-efficiency water-to-water system is an in-floor heating application demanding 90°F to 100°F water with no fan-power requirement. An example of a low-efficiency system is a high-static-pressure VAV application requiring 125°F water.

Water-to-air heat pumps are rated by capacity (British thermal units per hour) and efficiency (energy-efficiency ratio [EER] in cooling mode and

coefficient of performance in heating mode), according to application and entering-liquid temperature (ELT).5 The rating conditions for water-to-air heat pumps are:

- Ground-loop heat pumps (GLHPs): 77°F ELT in cooling mode, 32°F ELT in heating mode.

- GLHPs (part load): 68°F ELT in cooling mode, 41°F ELT in heating mode.

- Ground-water heat pumps (GWHPs): 59°F ELT in cooling mode, 50°F ELT in heating mode.

- Water-loop heat pumps (WLHPs): 86°F ELT in cooling mode, 68°F ELT in heating mode.

The rated entering-air temperatures (EATs) are 80.6°F (with 47-percent RH) in cooling mode and 68°F in heating mode. Capacities and efficiencies do not include the fan or pump power required to distribute air and water through the duct and piping systems.

Optimal commercial-system design typically results in ground loops operating in the 80°F-to-90°F range in cooling mode and the 45°F-to-55°F range in heating mode. Therefore, the WLHP ELT of 86°F would be the closest indicator of cooling capacity and EER. In heating mode, the GWHP ELT of 50°F would be the appropriate condition for most commercial applications. Figure 5 compares the rated efficiencies of two high-efficiency GLHP product lines with efficiencies corrected for an ELT of 85°F and an EAT of 75°F and includes representative fan external static pressures at standard airflows (400 cfm per ton). Generally, the smaller the heat pump, the greater the efficiency. With dual-capacity heat pumps rated with 68°F condenser water, rated efficiencies can be misleading, if full-load efficiencies are not included in specifications.

Ventilation air is best provided with a dedicated outdoor-air system with a heat-recovery unit, especially in colder climates. While some contend this is an unnecessary expense for a central air-distribution system, it increases ventilation efficiency and decreases outdoor-air-conditioning requirements.

The added cost of a ground loop is significant, ranging from $3 to $8 per square foot. The economic viability of GSHPs can be enhanced by avoiding unnecessary items that are standard with conventional HVAC systems. If a quality ground loop is installed, simple, cost-effective controls, such as zone thermostats, should be sufficient.

References

1) EIA. (2003). Commercial building energy consumption survey. Washington, DC: Energy Information Administration.

2) Spilker, E.H. (1998). Ground-coupled heat pump loop design using thermal conductivity testing and the effect of different backfill materials on vertical bore length. ASHRAE Transactions, 104, pt. 1, 775-779.

3) Impact of grout on required GSHP bore length. (1998, April). Outside the Loop, p. 1. Available at http://geokiss.com/tech-news/vol1no2.PDF

4) ASHRAE. (2007). 2007 ASHRAE handbook--HVAC applications (ch. 32). Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

5) AHRI. (2008). Directory of certified product performance, water-to-air and brine-to-air heat pumps. Arlington, VA: Air-Conditioning, Heating, and Refrigeration Institute. Available at http://www.ahridirectory.org/ahridirectory/pages/ariDirectoryMain.aspx

Additional information on GSHPs can be found at http://geokiss.com.

Sidebar: Engineers K.I.S.S. and Tell

'Keep it simple and solid,' that is

In 2004, McLean County District Unit No. 5 in central Illinois replaced the HVAC systems at six of its oldest elementary schools with GSHPs.

"Installation costs were under $20 per square foot, and our overall energy costs have been reduced by over 40 percent," Jeff Monahan, district construction coordinator, said. "Maintenance requirements have also been reduced to only standard PM work. Our students and staff are very pleased with the new ground-source systems, with better classroom control and an overall reduction in noise level."

Kirk Mescher, PE, of Columbia, Mo.-based CM Engineering Inc. is largely responsible for the success of the district's GSHP designs. He was able to reduce installation, energy, and maintenance costs with a novel and simple combination of features, including:

- A vertical ground loop designed to maintain loop temperatures between 45°F and 85°F.

- A one-pipe interior water-distribution loop.

- Packaged low-noise water-to-air heat pumps with low-head circulation pumps.

- Zone thermostats.

Energy use is monitored closely as part of the Energy Ed program. Bruce Boswell, manager of the program, noted that all GSHP schools in the district have achieved an Energy Star rating above 83 without lighting or envelope upgrades.

In Austin, Texas, ground-loop contractor Lonnie Ball of Ball Drilling Co. maintains a list of more than 100 GSHP systems with 17,423 vertical bores that he and others have installed in the area since 1985. As in McLean County, the early installations were retrofits, and the unitary heat pumps, as shown in Photo B, worked well. Although other engineers installed a few central systems, loops in newer schools in surrounding districts are almost exclusively unitary.

"I talk to the people in our office and encourage them to design systems that keep in mind what our local work force is capable of doing," Mike Green of MEP Engineering Inc. in Austin said. "The number of quality people is going down. They are still out there, but there is a greater chance that the contractor that is low bid on the project is not going to have people with a high level of skill. So we need to ‘keep it simple.'"

A professor emeritus of The University of Alabama and a fellow of both the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and ASME International, Steve Kavanaugh is the author of "HVAC Simplified" and a co-author of "Ground Source Heat Pumps," both publications of ASHRAE. Over the years, he has conducted more than 100 professional-development seminars on ground-source heat pumps and HVAC energy efficiency.