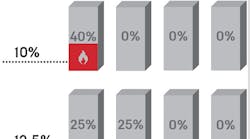

The United States’ infrastructure for power transmission and distribution is aging and, in many places, has difficulty meeting the demands placed on it. Local utility companies produce power on a large scale at a distance from sources of usage, with as much as 25 percent of the energy lost during delivery. Using the same natural resources, cogeneration plants eliminate those losses and function in excess of three times more efficiently than local utility companies.

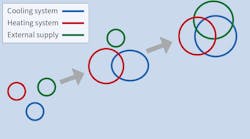

Cogeneration is the production of electricity using waste heat (as in steam) from an industrial process or the use of steam from electric-power generation as a source of heat. Typically, this process generates power at the point of usage and is co-located where waste heat can be utilized to the greatest (most efficient) extent possible. It has a proven energy efficiency exceeding 88 percent.

Cogeneration plants help to offset energy loss through distributed generation and support sustainability by removing load from our power infrastructure. They can be an important component of an energy-security or net-zero strategy and can help to control a facility’s power needs and protect investments from the utility grid.

Utilizing Technology Changes

A host of technologies used in on-site power generation at commercial, industrial, municipal, health-care, and educational properties exist and are well-established. These technologies, which include reciprocating engines, turbines, and fuel cells, are leading edge, but no longer bleeding edge, meaning the inevitable growing pains from their initial application have been experienced, with valuable lessons learned and improvements made. Vendors can and will support interested customers in learning, creating optimized solutions, and avoiding pitfalls.

The United States is enjoying increased availability of fuel, along with low natural-gas costs (see “Pipeline Changes Keep Natural-Gas Prices Falling,” Managing Your Facilities, January 2014). As a result, small cogeneration sites have the opportunity to be competitive against their large-scale utility counterparts. Also, decision makers are becoming increasingly aware of cogeneration, providing several opportunities to present business models that break the status quo of on-site power/waste-heat utilization. Incentives, rebates, and tax credits are available to customers willing to leverage them.

Overcoming Challenges

Along with benefits from cogeneration come certain risks. Cogeneration has been implemented at a number of sites with the best of intentions and planned outcomes only to become a stranded asset.

One particular challenge is fuel-cost risk. History has taught us that to model a cogeneration facility economically, we must assume fuel costs will vary directly and proportionally with power costs, which does not always happen. Collaboration with an experienced partner helps to reduce this risk through proper gauging of exposures, establishment of boundaries, and hedging as necessary.

Another considerable issue concerns experience. Evaluation and engineering is much more complex and nuanced for a single solution to energy, heating, and cooling needs than it is for separate solutions. To overcome this challenge, work with an engineering partner that can successfully lend its experience to the specific installation and operation requirements.

Lastly, many cogeneration systems and facilities have failed because of a management change or lack of understanding. The former introduces new parties who may not be fully aware of the requirements or the importance of a cogeneration facility, while cases of the latter never stood a chance. The right partnering mix brings together a committed customer, successful technology vendor, seasoned and insightful engineers, quality installers, and a dedicated operation and service team.

Key Considerations

In assessing the potential advantages of cogeneration, consider:

• Steps that have been taken for conservation of heat and power.

• The use and location of the facility.

• The square footage of the facility.

• The age of the facility.

• The base, peak, and mean electrical load.

• The consistency and minimum/maximum requirements of the thermal load.

• The average thermal load.

• The simultaneous-heating or cooling and electric-power hours per year.

• The minimum, maximum, and average cooling loads.

• The main hours of operation of the facility.

• The blended, pure-consumption, and demand kilowatt-hour cost.

• The electrical-rate structures/seasonal transition.

• The space available for a cogeneration plant, as well as the estimated interconnection distance.

• Any concerns about electrical reliability.

• The cost of natural gas/fuel.

• What the heat will be utilized for.

Because natural-gas prices are low and backup generation is critical, cogeneration is becoming more prominent. Effective implementation involving new technologies and the right partners ultimately will help to achieve energy goals, energy security, and affordable renewable technology.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].