According to the U.S. Energy Information Administration, commercial buildings account for approximately 20 percent of annual energy consumption in the United States. Within commercial buildings, a significant amount of energy is used by HVAC systems, including fans. By some estimates, fans account for roughly 15 percent of the energy used in commercial and industrial buildings and processes.

The large amount of energy consumed by fans has led to industry standards and government regulations establishing minimum fan efficiencies. The goal is to drive development and selection of more-efficient fan products. Thus, it is important to have a basic understanding of fan-efficiency regulatory efforts, limitations of fan-efficiency regulations, and how to apply standards and codes to minimize fan-power consumption.

Fan-Efficiency Standards and Codes

ANSI/ASHRAE/IES 90.1-2013, Energy Standard for Buildings Except Low-Rise Residential Buildings, is the first energy standard to reference minimum fan-efficiency targets. With the U.S. Department of Energy (DOE) mandating all states certify their energy codes meet or exceed ANSI/ASHRAE/IES 90.1-2013 by Sept. 28, 2015, and adopt those requirements by Sept. 26, 2016, it is important to understand the limitations and potential unintended consequences of the regulation.

Regulation Limitations

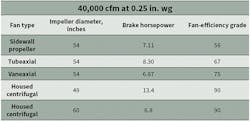

ANSI/ASHRAE/IES 90.1-2013 requires fans have a fan-efficiency grade (FEG), as defined in AMCA 205, Energy Efficiency Classification for Fans, of 67 or higher. Because it is based only on a fan’s impeller diameter and a single point of operation at peak total efficiency, FEG alone fails to provide a true indication of a fan’s actual power consumption. While one might expect a fan with a higher FEG to use less energy than a fan with a lower FEG, that is not always the case, as shown in Table 1.

Because of the limitations of FEG, ANSI/ASHRAE/IES 90.1-2013 states a fan’s total design-point efficiency must be within 15 percentage points of its maximum total efficiency. Further, limitations of FEG require a significant number of exceptions, including:

- Single fans with a motor-nameplate horsepower of 5 or less.

- Fans in series or parallel (e.g., fan arrays) with a combined motor-nameplate horsepower of 5 or less operated as the functional equivalent of a single fan.

- Fans that are part of equipment listed under Section 6.4.1.1.

- Fans included in equipment packages bearing a third-party-certified seal for air or energy performance.

- Powered wall/roof ventilators.

- Fans outside the scope of AMCA 205.

- Fans intended to operate only during emergency conditions.

Future Direction of Fan-Efficiency Regulation

In addition to mandating states adopt energy codes equal to or better than ANSI/ASHRAE/IES 90.1-2013, the DOE is developing a federal regulation establishing a maximum fan electrical power (FEP) for any given design point of operation (i.e., cubic feet per minute/pressure). FEP will be used to establish fan-energy indexes (FEIs) for easily comparing relative power consumption at a given point of operation. FEI is a simple ratio of “baseline” FEP to actual electrical input power at a fan’s design point:

FEI = baseline power ÷ fan power

where:

Baseline power is a function of airflow and pressure

FEI accounts for both static and total pressure regardless of whether a fan is categorized as ducted or unducted. Manufacturers will be required to limit fan sales to models with FEIs equal to or greater than 1.0 (where the required fan power is less than the baseline power). Eventually, the DOE will increase the FEI threshold.

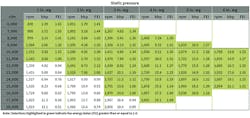

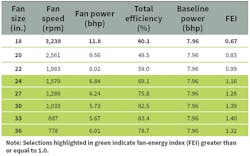

Manufacturers are expected to present allowable selections to fan-system designers much as they do today, using catalog tables and product-selection programs. Tables 2 and 3 show how FEI will be used to present compliant performance ranges (i.e., FEI equal to or greater than 1.0).

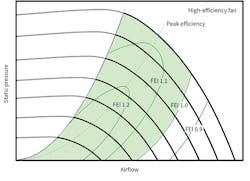

The FEI metric is designed to allow market flexibility and trade-offs. Depending on the application, designers may select fans for a very specific point of operation or select a fan for a range of performance. This will drive manufacturers to design products that maximize both the FEI metric and the size of the FEI performance bubble.

The FEI metric makes justifying and pushing for higher levels of fan efficiency easy and practical. For example, a fan with a FEI of 1.0 will use 20 percent more energy than a fan with a FEI of 1.2. This will allow building owners and operators to justify the additional cost of fans with higher efficiencies. Also, it may assist code officials and utilities in justifying costs for fans with higher efficiencies to qualify for rebates or incentives.

DOE fan regulation is in the early stages of development. A 25-member working group appointed by the DOE, the Appliance Standards and Rulemaking Federal Advisory Committee, has completed work on a regulation “term sheet” consisting of 32 recommendations to be considered by the DOE as it develops the final regulation. While the working group provided consensus recommendations to the DOE on many items, including the FEP and FEI metrics, no consensus was reached regarding more important items, such as minimum efficiency levels and replacement fans.

The term sheet was submitted to the DOE in September 2015. Prior to issuing a final rule, the DOE will seek industry review and comment. As of this writing, the DOE is in the process of developing the proposed rule, and a firm date as to when the rule will be available for public comment is not available. Once the final rule is published, manufacturers are expected to have five years to bring all of their products into compliance.

Status of Fan-Efficiency Regulation in the United States

The DOE is working aggressively to drive regulations that will reduce energy consumption in the United States. Mandates for states to adopt energy standards that meet or exceed ANSI/ASHRAE/IES 90.1-2013 and develop regulations establishing minimum levels of fan efficiency soon will be impacting the industry. As with any new and developing regulations, it is important to understand the opportunity and limitations of these regulations. FEI addresses the shortcomings of the FEG requirements in ANSI/ASHRAE/IES 90.1 by:

- Providing a comparative metric across all fan types and sizes.

- Eliminating exceptions.

- Allowing for a simple method of encouraging “stretch” efficiency requirements.

Fan-efficiency regulation is here to stay. It is changing at a rapid pace and likely will continue to evolve over the next several years. FEG requirements will be replaced as DOE fan-efficiency regulation takes effect. Until then, the best way for engineers and contractors to ensure fans use the least amount of energy, regardless of regulation, is to continue to:

- Select fans based on the lowest operating power.

- Specify fans be licensed to bear a third party (e.g., AMCA) seal for air performance.

- Install fans with efficient inlet and outlet conditions, minimizing “system effect.”

Anthony (Tony) Rossi is vice president of marketing for Greenheck Fan Corp. He has served on ASHRAE and Air-Conditioning, Heating, and Refrigeration Institute (AHRI) standards-development committees and on ASHRAE Technical Committee 9.10, Laboratory Systems. He has bachelor’s and master’s degrees in mechanical engineering from the New Jersey Institute of Technology. Michael Wolf, PE, is director of regulatory and industry relations for Greenheck. He is active with ASHRAE, Air Movement and Control Association (AMCA) International, the U.S. Department of Energy, UL, AHRI, EU, and the International Organization for Standardization and is a member of the AMCA task force working to develop a viable fan-efficiency metric. He has a bachelor’s degree in engineering from the University of Wisconsin–Madison.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].