Just as today’s cars are designed and built much differently than cars from the 1970s, so too are air-delivery systems in commercial buildings. Sadly, 70s-style air systems that look and behave like the gas guzzlers of the past are still being designed and built today.

This article documents how today’s high-performance air systems (HPAS) make use of more efficient application engineering, equipment, and control logic. According to a committee within AMCA International—consisting of AMCA member companies and non-members—have defined HPAS as follows:

- Apply modern design approaches with leading-edge products and technology to optimize energy efficiency, comfort, and indoor air quality.

- Integrate the strategies of right-sizing, free-cooling using outside air, and small thermally similar control zones and minimize static pressure, system leakage, and system effects.

- Technologies include high-efficiency fans with variable-speed capacity controls, low-leakage outside-air economizers, low-leakage ducts and fittings, low-pressure-drop components (filters, coils, ducts and diffusers), diagnostic monitoring, and digital controls.

High performance air systems are not a product—they’re not purchased off the shelf as a complete package. HPAS are a result of industry professionals thinking differently about air systems in new construction and substantial renovations to deliver better comfort, lower energy use, and competitive installed cost.

In practical terms, HPAS follow the design guidelines listed below. Actually, this list is truncated so we can fit it all into this short article. To really understand how these guidelines combine to deliver a better system without driving construction costs over tight budgets, please visit the AMCA Website.

These guidelines are in accord with ASHRAE’s “Advanced Energy Design Guide for Small to Medium Office Buildings: Achieving 50 % Energy Savings Toward a Net Zero Energy Building.”

Select the Lowest-HP Fan and Vary the Speed

Every HPAS varies fan speed with a change in load—even single-zone systems. Selecting the right fan, minimizing power at design conditions, and maximizing savings at part-load depends on how you control and how you apply the fan. For example:

- Right-size the fan, selecting as close to peak efficiency as capacity controls will allow.

- Use high-efficiency airfoil centrifugal fans. Maximum fan power should not exceed 0.72 W per cfm.

- Use a more efficient scroll type when noise and space limits allow. Use plenum fans when space is constrained.

- Use electronically commutated motors and speed controls where possible (now available up to 15 hp).

- Use variable-speed drives (VSD) on fans with induction motors.

- Control the VSD from a static pressure sensor located close to the last variable air volume (VAV) terminal in the duct run. Use multiple sensors for ductwork with multiple branches. (See “Specify Controls for Low-Energy VAV” below). This capacity-control approach enables fan selections closer to peak efficiency.

- Use the lowest-pressure-drop air system possible (See “Design for the lowest possible pressure drop in the VAV system”).

- Specify that no balancing damper shall be installed before the last VAV terminal or the last diffuser (alternatively that the balancing damper before the last VAV terminal or last diffuser shall remain open) so that the system will be balanced at the lowest possible fan speed.

Eliminate the Need for Reheat

Modern VAV systems do not reheat cooled air. In the winter, ventilation air is delivered to zones at temperatures needed to serve zones calling for cooling. Heating in perimeter zones is limited to times when primary airflow is based only on ventilation demand. This requires careful zoning, added perimeter insulation, heat recovery from warm ceiling plenum air, and demand-based ventilation control.

Other tips for eliminating the need for reheat include:

- Adding enough inexpensive insulation to the building envelope until the heat loss through the envelope at outside temperature below winter design is less than the heat gain of the occupants and other internal loads in perimeter spaces. Morning warm-up heating may still be required, but this can be supplied before cooling load is present.

- Having shrunk the perimeter-heating zone as much as possible, use separate air handling units for each heating zone exposure and separate air handler(s) for the interior.

- Recover heat in the ceiling plenum using fan-powered boxes on the perimeter.

- Activate mechanical heat only when cooling flow is at its minimum to satisfy ventilation requirements.

- Use high-induction diffusers to reduce stratification. All VAV diffusers must be high induction to deal with flow variations.

- Use the lowest possible minimum-flow setpoint. It must be the higher of the minimum ventilation requirement or the lowest allowed by the VAV diffusers (10 percent of design airflow).

- Use supply-air-temperature reset. An increase in supply-air temperature will require a larger volume of air, but the higher supply temperature will eliminate (or minimize) reheat. Good zoning and perimeter insulation makes this unnecessary, but where simultaneous heating and cooling in one air system is unavoidable, use modeling to find the ideal compromise between supply temperature, reheat energy, and fan energy.

- Increasing the use of fan energy to lower the use of central plant energy cannot be justified, except when also reducing reheat. One method is to reset supply-air temperature during cool weather and size interior zones for 60°F or higher supply air. Supply-air reset may not be beneficial in warm climates and in high-humidity locations where alternate dehumidification may be required.

Small Zones Improve Comfort and Reduce Overcooling/Overheating

Try to provide a VAV zone and a thermostat for each occupant. This can be done cost-effectively with diffusers that incorporate temperature-control dampers.

For Lowest Pressure Drop in VAV System—Use Low Supply-Air Temperatures and Temperature Reset

Large components, smooth transitions, unobstructed fan inlets, and fully developed fan discharges matter. Ducts can be smaller if design supply temperatures are lower. This approach, coupled with supply-temperature reset, saves enough on ductwork to fund many other attributes of HPAS without driving installed costs too high.

Coils

Select the largest coil that can fit in the space. Coils should have a minimum waterside delta-T of 15°F and face velocities between 300 and 450 fpm.

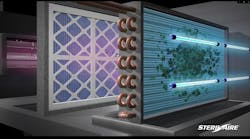

Filters

- Use the largest filter bank that can fit in the space.

- Select low-pressure-drop extended-surface-area filters.

Fan

- Minimize fan-system effects with an unobstructed inlet and a straight run of duct or an elbow in the direction of the fan rotation at the outlet.

- Use the minimum duct liner only when necessary for sound attenuation. Avoid sound traps by selecting larger, quieter, more efficient fans and using components with low face velocities.

Risers

- Place the shafts close to the air handler.

- Deliver air from rooftop units inside an insulated roof curb to avoid ducts outside the building envelope.

- Size for 800 to 1,200 fpm closest to the air handler.

- Consider multiple air shafts for large floor plans.

Supply-Air Ducting

- Use leak-tight, aerodynamic round duct designed using static regain to reduce fan load and duct pressure. In many cases, this means using round or oval duct with gasketed connections and fittings.

- Use multiple home runs to a discharge plenum. This saves space, money, and energy.

- Make ducts as straight as possible with a minimum of transitions and joints.

- Use large-radius elbows and low-pressure-drop fittings and takeoffs.

- Size for 700 to 1,200 fpm or pressure drop no greater than 0.08 in. wg per 100 ft.

- Limit use of flex ducting to a maximum of five feet at diffusers.

- Use duct liner only where necessary for sound attenuation. Avoid sound traps.

VAV Diffusers

- Size VAV diffusers for low static-pressure drops: between 0.25 and 0.05 in.wg.

- Size VAV diffusers as large as possible, especially at the end of the duct run, for the lowest possible pressure drop at design airflow.

Balancing Dampers

No balancing damper should be installed before the last VAV diffuser (alternatively that the balancing damper before the last VAV diffuser shall remain open) so that the system will be balanced at the lowest possible fan speed.

Return Air

- Provide at least one return-air grille for each VAV zone, more if the zone is large.

- Size return grilles for pressure drop no greater than 0.08 in. wg.

- Use ceiling return-air plenums (except in high-humidity locations, such as DOE climate zone 1). Seal ceiling plenums for minimum air infiltration.

- Size return ducts for pressure drop no greater than 0.04 in. wg per 100 ft.

Minimize Ventilation, Exhaust, and Makeup Air

Ventilation must be controlled to match occupancy down to some minimum level associated with unoccupied space. In VAV systems, the outside air delivered to each zone has to be compared to the need, and controlled accordingly.

- Use occupancy or carbon dioxide (CO2) sensors.

- The controller must calculate actual outdoor airflow to each control zone based on the percent outside air (OA) in the supply air per formula from ASHRAE Standard 62.1, “Ventilation for Acceptable Indoor Air Quality.”

- Consider using an OA/exhaust-air heat-recovery system

- Obtain free cooling by using economizers except in DOE climate zone 1. Use airside (rather than waterside) economizers. Control is based on enthalpy sensors.

- Use exhaust (rather than return) fans when necessary to maintain building pressurization during economizer operation. Use AMCA Class 1A low-leak dampers and weather-resistant louvers with certified ratings to match worst-case weather conditions.

- Use the multiple-zone recirculating-ventilation system design approach from ASHRAE Standard 62.1, which allows ventilation air to be controlled from measured CO2 levels in key zones and return air, rather than the sum-of-peak zone population at design.

Specify Controls for Low-Energy VAV

Lowering design cooling temperatures saves a bundle on ductwork. To minimize the energy penalty of this approach, raise the temperature at part load. Control fans from a pressure sensor placed near the end of the longest run. The closer to the end this sensor is placed, the more efficient the fan selection and operation can be.

Static pressure

- Even if there is only one zone, vary the airflow with a change in the demand for cooling. Single-zone systems require no control dampers, but the air handler (or packaged unit) should vary flow with demand.

- For multiple-zone VAV systems, control the VSD from a static-pressure sensor located near the end of the duct run. Use multiple sensors for ductwork with multiple branches.

- Locate the static-pressure sensors close to the last VAV diffuser in the duct run.

Supply-air temperature (SAT)

- For systems with multiple zones, control cooling and heating with a discharge-air thermostat for constant SAT, and reset to satisfy the zone with the strongest call for cooling at the highest temperature possible.

- Design cooling SAT at 50°F and reset to 58°F to 61°F depending on climate zone (and the need for latent cooling). For SAT reset in humid climates, use at least one zone humidity sensor to disable reset if humidity exceeds 60 percent.

- Perimeter/skin-system heating SAT must be as low as possible but no lower than 80°F.

- Changeover between heating and cooling may be manual, with a room thermostat or multiple voting room sensors. Locate the room thermostat in the room of “greatest need” or maybe the most important room.

Optimal Start

- Use a system controller that waits as long as possible before starting the system so that the temperature in each zone reaches occupied setpoint just in time for occupancy.

Tune the System by Re-engineering for What “is” Post installation

Design tools available to the air-system designer are coarse. System effects in ductwork, and installation adjustments cannot be estimated properly Re-engage with the project during test and balance—uncover the system challenges that compromise performance. Change some things—make it right.

Monitor Performance and Alert Operators of Faults

Once you have the system tuned and operating as you intend, monitor performance. It costs very little to track airflow and pressure at critical points in a system. Track power consumed by the fan, comparing power draw (kw) and power use (kwh) to cooling and heating demand, and to average peak and minimum flow rates. Expose actual performance over time to someone who is intimate with the design expectations.

When performance degrades, find the problem, and see that it is corrected. This is easier than you think, but that’s the point. You have to think about and implement this capability into your design.

- You need the means to record and convey history of operations, conditions, and efficiencies.

- You need the means to document preventive maintenance.

- The designer must never forget that the primary purpose of HVAC is comfort for building occupants. Fortunately, comfort and saving energy go hand in hand with high performance air systems.

These design guidelines for HPAS are just an overview. For more information about high performance air systems, visit www.amca.org/feg/hpas.aspx.

References

Ivanovich, M. (February, 2014), 14 tips for reducing wasted fan-system energy, HPAC Engineering, pp 6-7, 21.

Smith, W. (Fall, 2013), The “New, most efficient thing” in commercial HVAC systems. AMCA inmotion.

ASHRAE (2011) Energy design guide for small to medium office buildings—Achieving 50% energy savings toward a net zero energy building, Atlanta ASHRAE. Also available at https://buildingdata.energy.gov/cbrd/resource/1174.

Kurt Herzog is president and CEO of Acutherm LLC, a position he’s held for 12 years. The 36-year-old manufacturing company is located in Hayward CA. Acutherm has 87 representative companies around the world. Mr. Herzog is the vice-chair of the AMCA International High Performance Air Systems Task Force.