With Replacement Wheels, Hospital Again Enjoying the Benefits of ERV

From the mid-1970s to early 1980s, the main building at Anna Jaques Hospital in Newburyport, Mass., was greatly expanded. To minimize the heating and cooling costs associated with 24/7 operation, the 100-percent-outdoor-air-handling systems serving the expanded facility were equipped with energy-recovery wheels.

The inclusion of energy-recovery-ventilation (ERV) technology in HVAC designs has proven to be a sound long-term investment for many types of buildings. The lower price of smaller chillers, boilers, and packaged rooftop units often offsets the initial investment in ERV, while annual costs of conditioning incoming outdoor air are lowered by as much as 80 percent.

With larger air-handling systems, the sheet-metal cabinet enclosure often outlives the internal mechanical components, which typically are replaced once, sometimes twice. The original energy-recovery wheels at Anna Jaques reached the end of their useful life after approximately 20 years of continuous service. With no way to effectively clean or restore the wheels and the manufacturer no longer supporting the product, the hospital’s facility maintenance staff was forced to remove the energy-transfer media.

The hospital’s senior director of support services, David Fowler, said the decision to remove the energy-transfer media came after several options were explored. A complete overhaul of the HVAC system was not affordable, and the replacement wheels Fowler researched would not fit through available access points into the mechanical rooms housing the air-handling units. The only solution at the time was to remove the media and forgo the benefits of energy-recovery wheels.

A Unique Solution

Several years later, while attending a facilities-management trade show, Fowler learned about Airxchange’s modular replacement-wheel design.

“Until I met with Airxchange, I was unaware of any replacement wheels that could be delivered and assembled within the tight quarters of our equipment rooms and air handlers,” Fowler said.

Airxchange replacement wheels feature non-corroding polymer energy-transfer-media segments that can be removed easily and cleaned as necessary to ensure optimal performance for the life of the product. The lightweight segments are held in place by a rigid structural stainless-steel wheel. The wheel, drive mechanism, and outboard wheel bearings are supported by a structural galvanized-steel cassette frame. Every component is designed to be assembled in the field with conventional hand tools (sockets, rivet gun, Allen wrenches). The entire field-replacement kit is assembled and tested at Airxchange’s factory before being shipped and assembled on site by an Airxchange-qualified technician.

Return on Investment

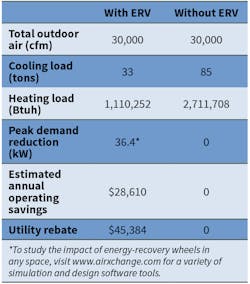

The Airxchange Aftermarket Energy Recovery Solutions team specified two 9-ft-diameter wheels that were sized to match the performance of the original wheels. Estimated total installed costs were presented to the hospital.

“Energy-efficiency projects compete for funding with other projects, such as investing in IT, so our proposals must present an attractive return on investment,” Fowler said.

With a pre-approved gas-efficiency incentive from utility provider National Grid, plus a budget number for preparing and buttoning up the air handlers following assembly of the replacement wheels, Fowler presented a proposal financially compelling enough for the hospital to move forward with the project.

Renewed Energy Savings

The results of Fowler and his technical staff’s efforts are two new and robust energy-recovery wheels expected to save energy for 20-plus years. Unlike their predecessors, the new wheels are completely serviceable, with a five-year warranty and a full complement of available replacement parts.

The unique modular design of the replacement wheels enabled Anna Jaques to once again recover valuable energy from exhaust air.

For Design Solutions author guidelines, call Scott Arnold, executive editor, at 216-931-9980, or write to him at [email protected].