Air pollution is a problem in public buildings. Studies show indoor air may be two to five times more polluted than outdoor air,1 causing or aggravating an estimated 50 percent of all illnesses2 and costing the U.S. economy upward of $160 billion in medical expenses and reduced productivity annually.3

Air filters perform an important function, providing a primary defense against both pollutants generated within and those drawn from outside a building.

Most of the particles people breathe into their lungs are 0.5 micron or smaller—a fraction of the size of a grain of sand. Not all air-filter media are capable of capturing such small particles efficiently. This article takes a close look at air-filter media and demonstrates how the right media and overall air-filter design provides higher-efficiency removal of respirable particles associated with poor indoor-air quality (IAQ) and can help to reduce the energy costs associated with operating an HVAC system.

How Filter Media Works

Air-filter particle removal is dependent on particles colliding with or being removed by the “fibers” that make up the filter media and the particles continuing to adhere to the media. The extent to which filters remove airborne particles is referred to as filtration efficiency.

The four primary methods of mechanical particle capture are:

• Impingement. High-density particles are captured as they resist change in airflow direction around filter-media fibers and collide with the fibers.

• Interception. Particles are captured based on forces of attraction as they come into direct contact with filter-media fibers.

• Diffusion. Very small particles are captured at lower air velocities because of Brownian motion, which increases the probability particles will contact fibers and stay attached to them.

• Straining. Straining occurs when the smallest dimension of a particle is greater than the distance between adjoining filter-media fibers.

Electret Treatments

There are two types of air-filter media: mechanical and electromechanical. Electromechanical media attracts particles that have a natural charge or that pick up a natural charge as they pass through air. Its particle-capture effectiveness can be enhanced with the addition of an electrostatic charge.

While electrostatically modified media include a broad range of materials, such as fibrillated electret-charged films and triboelectrically charged needled felts, most air-filter media is filament-based, using one of a number of nonwoven forming techniques and synthetic-fiber types, including meltblown polyolefins and spunbond polyolefins. Corona charging generally is considered the best method for large-scale electret treatment of electromechanical air-filter media.

There are several benefits of electret treatment of filter media:

• High initial and sustained efficiency. Mechanical filters begin their life at their lowest particle-removal efficiency, relying on the buildup of dust cake to increase their efficiency.

• Improved submicron-particle capture efficiency. While submicron particles are much smaller than the void spaces in most commercial electret media, the electrostatic forces within the media structure allow those particles to be removed with high efficiency.

• Resistance to age-related decay. Studies have shown the efficiency of electret-treated filter media to be unaffected by relative humidity and long-term warehousing at high temperatures (130°F).

• Reduced energy consumption and costs. The filtration mechanisms in mechanical filters disrupt particles in air streams, creating resistance. The greater the resistance, the greater the energy required to push air through a filter (Figure 1). The lower airflow resistance of electromechanical filters means reduced energy consumption, energy costs, and greenhouse-gas generation. Additionally, mechanical filters typically require more filter media than electromechanical filters do to attain a given level of filtration. In many cases, the additional mass consumes more non-renewable natural resources.

It is important to remember that an electret treatment is an enhancement of an underlying mechanical structure. The combination of different electret-treatment patterns/charge distributions and mechanical structures means not all electromechanical filters are created equal.

Selecting the Right Air Filter

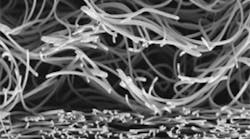

Filters with a robust mechanical structure and an electret treatment almost always outperform filters relying solely on mechanical efficiency. Thus, it is important to look for a filter with electret-treated depth-loading media with loosely packed fibers on the upstream side and densely packed fibers on the downstream side (Photo A). This structure helps to reduce airflow resistance, enhance dust loading, and prevent face loading.

ANSI/ASHRAE Standard 52.2-2007, Method of Testing General Ventilation Air Cleaning Devices for Removal Efficiency by Particle Size, measures fractional particle-size efficiency (PSE), an indicator of an HVAC filter’s ability to remove particles between 0.3 and 10 micrometers in diameter. A minimum-efficiency reporting value (MERV) is assigned to a filter based on a minimum PSE. MERV 1 is least efficient, while MERV 16 is most efficient. For office buildings, recent studies suggest a MERV of 7 to 11 or better for HVAC-system cleanliness and efficient operation.

It is important to note that two similar filters with the same MERV rating—one using mechanical media and the other electromechanical media—can have different filtration efficiencies and initial pressure drops. To dig deeper, it is important to review each filter’s ANSI/ASHRAE Standard 52.2 test report. Examine the filters’ efficiencies in all particle-size ranges: E1 (very fine particles in the 0.3-to-1.0-micrometer range), E2 (fine particles in the 1.0-to-3.0-micrometer range), and E3 (coarse particles in the 3.0-to-10.0-micrometer range). E1, E2, and E3 efficiencies are the truest measures of filter performance, giving users the most complete picture of particle-capture performance. High E1 and E2 efficiencies (at least 25 percent for E1 particles and at least 65 percent for E2 particles) are critical for good IAQ.

Additional Performance Factors

In addition to ANSI/ASHRAE Standard 52.2 performance factors, the following should be considered in an evaluation of filters:

• Energy efficiency. How does the filter’s resistance to airflow affect the energy consumption of the HVAC system? Energy expenditures can account for about 81 percent of the annual operating costs of an air-filtration system.

• Moisture resistance and temperature limitations. How is the filter affected by high humidity/moisture and temperature?

• Sustainability. Consider the entire product life cycle when selecting filters—from raw-material sourcing to manufacturing, packaging to transport, and design and use to final disposal.

• Filter style. Filter style is an important consideration. For example, some filters require binders and glue for stiffness. These can clog the “pores” of the filter media. The result can be restricted airflow; lower dust-holding capacity, which leads to more frequent filter changeouts, increased maintenance, and, sometimes, filter blowouts; and less efficient particle removal.

Conclusion

There are many styles of HVAC air filters, but only a few commonly used types of filter media. In the past, filter media was viewed as a commodity and specified based solely on purchase price. Today, facility professionals are more aware of costly medical and productivity issues associated with poor IAQ than ever before. In their efforts to improve IAQ for better occupant health and productivity and reduced medical costs and minimize energy expenditures, they are realizing the value and benefits of air filters.

References

1) U.S. Environmental Protection Agency, http://www.epa.gov/air/basic.html#indoor.

2) American College of Allergy, Asthma & Immunology.

3) Fisk, W.J. (2000). Health and productivity gains from better indoor environments and their relationship with building energy efficiency. Annual Review of Energy and the Environment, 25, 537-566.

Since joining Kimberly-Clark in 1991, Tony Fedel, PE, has held a variety of positions in sales/business development, operations, research, and engineering. Currently, he is associate marketing director for Kimberly-Clark Professional Partnership Products, which includes roll goods used in protective fabrics, filtration, sorbents, acoustic insulation, medical applications, packaging, and wipes.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].