Direct Gas-Fired Air-Handling Units

Direct gas-fired air-handling units (AHUs) have provided efficient, reliable makeup air for many high-exhaust/infiltration industrial applications and facilities, such as paint booths, distribution centers, warehouses, and factories. Concurrently, direct gas-fired AHUs have seen limited utilization in commercial applications, with commercial-kitchen makeup AHUs being the most prevalent application. With ever-increasing energy costs, it is time to take another look at direct gas-fired makeup AHUs for commercial applications.

- To see how some are altering air-handling systems to battle COVID-19, click here.

This article will describe the differences between direct and indirect gas-fired AHUs, provide component descriptions for a typical direct gas-fired AHU, highlight applicable codes/standards and any commercial-application limitations, note the advantages and disadvantages of direct gas-fired AHUs, and provide a number of potential commercial direct gas-fired AHU applications.

DIRECT VS. INDIRECT GAS-FIRED AHUS

There are two primary gas-fired AHU types: direct gas-fired and indirect gas-fired. It is important to understand the differences between these two AHU types.

Direct gas-fired

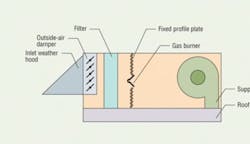

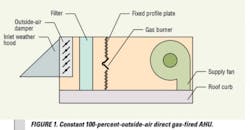

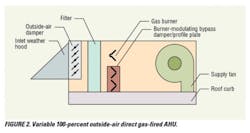

A direct gas-fired AHU has a gas burner installed directly in the outside makeup-air stream. The products of combustion (carbon dioxide [CO2], carbon monoxide [CO], nitrogen dioxide [NO2], aliphatic aldehydes, and water vapor) are discharged into the makeup-air stream and supplied to the building or process. Figures 1 and 2 show diagrams of non-recirculating direct gas-fired AHUs, and Figure 3 illustrates a recirculating direct gas-fired AHU.

Indirect gas-fired

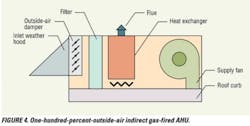

An indirect gas-fired AHU has a sealed combustion chamber in which all products of combustion are discharged through a flue to the outside environment and no products of combustion are discharged within the makeup air supplied to the building. Figure 4 shows a diagram of an indirect gas-fired makeup AHU for a system utilizing 100-percent outside air. Similarly, such equipment also frequently is utilized for recirculating-air applications.

DIRECT-GAS-FIRED-AHU COMPONENTS

Though simple in appearance, direct gas-fired AHUs have sophisticated burner-control systems. Unit sizes range from 1,600 cfm with a heating capacity of 94,000 Btuh to 120,000 cfm with a heating capacity of 18 million Btuh. Direct-gas-fired-AHU components usually include housings, outside-air intakes, intake dampers, filters, burners, and supply fans.

AHU housing

AHU housings are made of galvanized or aluminized steel. Access panels are provided to access dampers, filters, burners, and fans/motors. AHUs located outside should be provided with a sloped roof and standing seam joints.

Outside-air intake hood/dampers

Outside-air intake hoods or weather hoods need to be designed for an installation's specific location and should be provided with bird screens. Outside-air intake isolation dampers are provided to prevent cold air from dropping through a unit into a warm building and warm air from escaping through a unit during colder months when it is not in operation. Low-leakage parallel-blade isolation dampers are preferable. The fan discharge is an alternative isolation-damper location.

Filters

A filter cabinet normally has 30/30 filters (with a minimum efficiency reporting value [MERV] of 8) in a V-bank configuration to increase filter area and reduce static-pressure drop across the filters. Higher-efficiency filters normally are not used.

Burners

A burner consists of cast-iron or aluminum pipe assembly with drilled gas orifices. The fuel/air mixture is controlled statically by perforated stainless-steel baffles attached to the pipe assembly. The burner can be placed in the outside-air stream only or in the outside/return mixed-air stream. However, to prevent potentially hazardous combustion byproducts of indoor-air contaminants, the burner should be placed in the outside-air stream only.

The required airflow across the burner must be within a specific velocity range (typically 2,500 to 3,200 fpm) for proper combustion. For variable-airflow units, a modulating bypass damper or profile plate must maintain the airflow velocity within the specified velocity range. If the velocity is not maintained within the specified range, the burner can experience inefficient operation, generate odors in the occupied spaces served, and create an undesirable increase in certain products of combustion.

Most manufacturers provide a standard gas train with their units (Figure 5). Direct-fired gas trains have a substantial turndown burner capability — typically, in the 20-1 to 30-1 ratio range, which allows operation with 4 or 5 percent to 100 percent of rated capacity. Most direct gas-fired AHUs have a supply-air temperature between 50°F and 100°F. Variables that determine which gas train is used include burner-heating-capacity rating (British thermal units per hour), gas-supply pressure, whether the unit is listed (Edison Testing Laboratories, Inc. or Underwriters Laboratories, Inc. [UL]) or unlisted, code requirements, and the owner's insurance carrier's requirements. Some insurance carriers require that specific gas trains be provided.

Fans

Fans typically are double width/double inlet (DWDI) with forward-curved or backward-inclined blades. Fans can come with open-drip-proof (ODP) or totally-enclosed-fan-cooled (TEFC) motors. Most manufacturers provide fans with a maximum external static pressure in the 2- to 3-in.-wg range. Because most supply-air temperatures are below 100°F, fan motors and bearings are rated to handle lower temperatures. For applications that require supply-air temperatures higher than 110°F, it is important to verify that motors and fan bearings are rated for maximum design operating temperatures when placed in draw-through configurations.

CODES AND STANDARDS

It is important to perform a detailed codes and standards search when considering a design utilizing direct gas-fired AHUs. There are two primary equipment standards and two primary codes that provide specific operating and application guidelines for direct gas-fired AHUs:

-

ANSI Standard Z83.4, Non-Recirculating Direct Gas-Fired Industrial Air Heaters. ANSI Standard Z83.4 is the primary equipment standard for 100-percent outside-air direct gas-fired AHUs and includes limitations on combustion byproducts (CO less than 5.0 ppm, NO2 less than 0.5 ppm, and CO2 less than 4,000 ppm), gas-ignition control, combustion-air control, and flame safety.

-

ANSI Standard Z83.18, Recirculating Direct Gas-Fired Industrial Air Heaters. ANSI Standard Z83.18 is the primary equipment standard for recirculating direct gas-fired AHUs and includes limitations on combustion byproducts (CO less than 25 ppm, NO2 less than 3 ppm, and CO2 less than 5,000 ppm), gas-ignition control, combustion-air control, and flame safety. The standard prescribes a limit on the air-temperature rise based on the percentage of recirculated air.

-

International Fuel Gas Code. The International Fuel Gas Code has separate sections to address non-recirculating direct-fired AHUs (Section 611) and recirculating direct-fired AHUs (Section 612). Both sections note that direct-fired AHUs cannot supply any area with sleeping quarters, makeup air must come from outside, motorized outside-air dampers/louvers must be proven open prior to burner activation, systems must be controlled properly to prevent building overpressurization, and burner controls need to have a burner purge cycle.

-

NFPA Standard 54, National Fuel Gas Code. NFPA Standard 54 has similar requirements as sections 611 and 612 of the International Fuel Gas Code. Its requirements differ depending on whether a direct-fired AHU is listed (Edison, UL) or unlisted. Unlisted direct-fired AHU discharge-air temperature is limited to 150°F.

ADVANTAGES

Advantages of direct gas-fired AHUs include higher energy efficiency, lower installation cost, free humidification, and inherent freeze protection. Disadvantages include potential space contamination and limitation to applications needing a minimum of 20-percent makeup air. It is important to evaluate all of the advantages and disadvantages of a particular application.

Freeze protection

A direct gas-fired AHU has no fluids to freeze. Electric resistant heaters and heat pumps also will not freeze. However, steam and hot-water coils are prone to freezing if not maintained and operated properly. At very low temperatures, the moisture produced within indirect gas-fired AHUs may condense and freeze within the combustion chamber. Direct gas-fired AHUs are a good choice for facilities that are used intermittently during the heating season.

Higher energy efficiency

Direct gas-fired AHUs are highly efficient because their burners are located in the supply-air stream, where all generated heat is transferred. Energy can be lost when radiant heat escapes through AHU casings or stoichiometric combustion — a process by which all fuel is burned ideally — is not realized. Typically, a direct-fired AHU is 100-percent-efficient with a 92-percent thermal efficiency, while an indirect-fired AHU has thermal efficiencies in the 76- to 80-percent range.

For example, let's look at an auditorium with an annual energy usage of 42,000 therms. An 80-percent-efficient indirect gas-fired AHU would produce an annual energy usage of 52,500 therms, while a 92-percent-efficient direct gas-fired AHU would produce an annual energy usage of 45,650 therms, resulting in an annual energy savings of 6,850 therms and an annual energy cost savings of $6,850 (based on $1 per therm).

Although the example illustrates the energy savings of direct gas-fired vs. indirect gas-fired AHUs, direct gas-fired AHUs are attractive when compared with most other heating sources. For example, a steam heating coil is supplied by a boiler, has a maximum efficiency of 80 percent, and experiences distribution-piping energy losses. An electrical-resistance heater technically may be 100-percent efficient, but its higher electrical-energy cost usually makes it a less attractive option. Heat pumps are energy-efficient when the outside air temperature is above 32°F, but lose their efficiency as the ambient temperature drops below freezing because they must be supplemented with electrical-resistance heat at those temperatures. High-efficiency hot-water boilers have efficiencies equal to or slightly higher than those of direct gas-fired AHUs, but they experience distribution-piping-energy, pumping-energy, and boiler-radiant-energy losses.

Lower installation cost

Smaller (less than 5,000 cfm) direct gas-fired AHUs have equipment costs similar to those of indirect gas-fired AHUs. As their sizes increase, direct gas-fired AHUs become progressively cheaper. AHU equipment costs are lower for units with electric heat, hot-water heat, and steam because they do not have burner-management systems.

Regarding auxiliary support equipment and required infrastructure, direct and indirect gas-fired AHUs only require gas piping. Steam systems require steam boilers, condensate-return systems, makeup-water systems, chemical-treatment systems, steam-distribution systems, combustion-air systems, flues, and gas piping.

Hot-water heating systems require hot-water boilers, hot-water distribution piping and pumps, makeup-water systems, chemical-treatment systems, flues, and gas piping. Electric systems need only electrical service. Taking an AHU and all of its associated auxiliary equipment into account, a direct gas-fired AHU has one of the lowest installation costs.

Lower internal AHU static-pressure drop

The static-pressure drop across direct gas-fired burners is lower than that across indirect gas-fired burners, hot-water coils, and steam coils, resulting in lower fan energy usage and cost.

Free humidification

Moisture is one product of combustion that a direct gas-fired AHU supplies to a facility/process. If a direct gas-fired AHU has a firing rate of 1 million Btuh utilizing gas with a heat content of 950 Btu per cubic foot, then 1,053 cu ft of gas is needed per hour, supplying 97.7 lb of moisture per hour to the facility/process. When a direct gas-fired AHU is utilized, facilities or processes that require humidification during the heating season may not need additional humidification or may need only lower-capacity humidification systems, resulting in lower installation and energy costs.

Lighter AHUs

Direct gas-fired AHUs tend to weigh slightly less than the other AHUs previously discussed. However, this difference normally is not enough to make a substantial change in the supporting structure needed.

DISADVANTAGES

Disadvantages of direct gas-fired AHUs may include:

High minimum makeup-air requirement

Facilities/processes that consistently require less than 20-percent outside-air makeup are not good candidates for direct gas-fired AHUs. The standard minimum outside-air percentage for direct gas-fired AHUs is 20 percent.

Unwanted humidification

When a direct gas-fired AHU is utilized, facilities/processes with low humidity requirements require additional dehumidification equipment to remove the resulting moisture from the supply-air stream, resulting in higher installation and energy costs.

Application limitations

NFPA Standard 54 prevents direct gas-fired AHUs from being used for sleeping quarters. It is important to remember that direct gas-fired AHUs supply products of combustion to facilities and that there must be a positive method of removing and diluting the concentration of these products, which includes removing air from each space being supplied.

Contamination

When using direct gas-fired AHUs, facilities/processes that are very sensitive to contaminants need to be evaluated carefully to determine whether the products of combustion are considered contaminants.

Potential odors

If a direct gas-fired AHU's gas burners are not tuned properly, facility occupants may smell unpleasant odors.

APPLICATIONS

Good direct-gas-fired-AHU applications include facilities/processes that have high exhaust/infiltration airflows, large open spaces with few smaller spaces, and no low-humidity-control requirements. As noted previously, direct gas-fired AHUs commonly are used in commercial kitchens. Other commercial facilities that might benefit from utilizing direct gas-fired AHUs include fitness centers/gyms, enclosed stadiums, auditoriums, large retail stores, car dealerships, airport terminals, and laboratories.

CONCLUSION

Though the consequences of poorly designed or installed direct gas-fired AHUs can be severe and possibly deadly, those that are well-designed and installed can provide economical, energy-efficient, and reliable service for the right applications.

BIBLIOGRAPHY

McLean, G.W. Direct gas-fired air heating systems. (2005).

Schultz, C.C. (2004, January). Heating large spaces. Engineered Systems.

Turpin, J. (2003, September). Confusion clouds revised standards. Engineered Systems.

Turpin, J. (2002, September). Makeup air makes for healthier buildings. Engineered Systems.

An engineering manager with Jacobs Engineering, Inc., Vincent A. Sakraida, PE, LEED AP, has 25 years of experience designing mechanical systems for high-technology facilities, as well as extensive experience designing central-plant, laboratory-utility, and HVAC systems.