Preventing Mold With Fiberglass Duct Insulation

Employing moisture-management tactics in commercial-building wall-assembly design to increase thermal efficiency and minimize the potential for indoor-air-quality- (IAQ-) threatening mold growth has become popular in recent years. Another important tactic for mold prevention is ductwork insulation. This article will discuss the role fiberglass duct insulation can play in mold prevention.

HVAC SYSTEMS: THE LUNGS OF A BUILDING

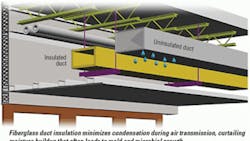

Mold and microbial growth often occurs inside uninsulated sheet-metal ductwork in which excess moisture is present. Caused by changing temperatures, this moisture often arises from condensation on the inside and outside of HVAC ductwork. During summer, beads of moisture form on the interior or exterior of warm, uninsulated ducts as cold air travels through. During winter, the same situation occurs as heated air travels through cold ducts. Condensation will occur on any duct surface when its temperature is equal to or lower than the dew-point temperature. IAQ concerns begin when condensed moisture mixes with dust or dirt in uninsulated ducts, fostering mold and microbial growth. If condensation is left untreated, mold and microbial growth will continue to worsen, leading to contaminated interior air.

Airborne mold spores can lead to discomfort and a variety of health problems among building occupants, including headaches, irritability, and severe respiratory ailments, such as asthma and Legionnaires' disease. ANSI/ASHRAE Standard 62.1, Ventilation for Acceptable Indoor Air Quality, provides guidelines for improving IAQ by combating these problems. Among other solutions, Standard 62.1 recommends adding fiberglass insulation to HVAC ductwork.

Well-insulated duct systems can help prevent mold growth by maintaining a constant ductwork temperature, significantly lowering the possibility of condensation on duct surfaces and protecting against microbial growth. According to the North American Insulation Manufacturers Association (NAIMA), fiberglass insulation is “inorganic and inert and does not support mold growth or act as nutrients for mold growth.”1 Fiberglass duct liners also are resistant to microbial attack, as described in ASTM C1338, Standard Test Method for Determining Fungi Resistance of Insulation Materials and Facings, and required by Standard 62.1 for HVAC air-stream surfaces. The duct liners also are in accordance with ASTM G21-96, Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi, and ASTM G22-76, Standard Practice for Determining Resistance of Plastics to Bacteria, as required by ASTM C 1071, Standard Specification for Fibrous Glass Duct Lining Insulation (Thermal and Sound Absorbing Material).

Four types of fiberglass insulation are common in ductwork applications:

-

Fiberglass duct liner

Applied to the interior of rectangular sheet-metal ductwork and designed to control heat loss or gain through duct walls, this type of insulation assists with quiet air distribution and condensation control. Fiberglass duct liners are resistant to mold growth and fiber erosion and prevent the distribution of airborne mold or glass fibers. When utilized with mat-faced air-stream surfaces, duct liners resist damage during installation, maintenance, and cleaning. Manufactured in roll and board form, they are available in a variety of densities and thicknesses.

-

Fiberglass duct wrap

Designed to fit snugly over rectangular, spiral, flat-oval, or irregularly shaped duct surfaces, fiberglass duct wrap is a blanket factory-laminated to a vapor-retarder facing, which can be cut and fit to achieve a thermally effective installation. Duct wrap also comes in various thicknesses and densities and usually is not specified in conditions in which ducts are exposed.

-

Fiberglass duct board

A 1- to 2-in.-thick rigid board made from resin-bonded inorganic glass fibers, fiberglass duct board is used to fabricate fiberglass ductwork for commercial applications requiring thermal insulation and condensation and acoustic control. Because insulation is integrated with the duct board, the extra fabrication steps required when applying thermal and/or acoustical insulation to sheet-metal ducts is eliminated. A factory-applied reinforced aluminum air barrier and a vapor retarder on the outside surface of boards protect fiberglass ducts from air leakage and moisture accumulation.

-

Fiberglass commercial-board insulation

Available unfaced or with foil/scrim/kraft (FSK) or all-service-jacket (ASJ) facings, fiberglass commercial-board insulation is applied on the exterior of round, rectangular, oval, or irregularly shaped ducts, plenums, chillers, and other HVAC equipment. Ranging from flexible to rigid, commercial-board products are used to reduce heat loss or gain through duct, plenum, or equipment walls.

In addition to moisture and mold control, duct insulation can help improve the quality of interior environments in two areas:

-

Energy conservation/temperature control

Most HVAC-system designs for commercial applications include insulated ductwork to minimize heat loss during winter and cool-air leakage during summer. HVAC ductwork needs to perform efficiently to conserve energy and keep utility bills at a minimum. When combined with properly sealed ducts, fiberglass duct insulation plugs potential leaks to allow improved thermal performance and occupant comfort.

-

Acoustic control

Noise travels fast through bare sheet-metal ducts and can cause reduced productivity and comfort and increased irritability among building occupants. Fiberglass duct insulation can absorb excess noise. Fiberglass and metal ductwork lined with acoustical insulation can help control undesirable clatter, such as aerodynamic, breakout, and mechanical-equipment noise and crosstalk.

REGULAR DUCT MAINTENANCE

Like any other building component, ductwork and duct insulation require proactive care for optimal performance. It is important to schedule periodic duct maintenance to keep ductwork clean and working.

High-efficiency air filters of the correct size and quantity are key components of a well-maintained HVAC system. Ducts should be inspected for the detection and remediation of moisture and contaminants regularly. If dust or debris is present, ducts must be cleaned in accordance with National Air Duct Cleaning Association (NADCA) ACR 2006 Standard, Assessment, Cleaning & Restoration of HVAC Systems. ACR 2006 requires an HVAC system to be under continuous negative pressure when cleaning is performed. Continuous negative pressure is accomplished through the use of a negative air machine. The standard also requires the use of agitation. The three most common methods of agitation are:

Contact vacuumingA conventional method of cleaning interior duct surfaces, the hose of a high-powered vacuum cleaner with a high-efficiency-particle-arrestor (HEPA) filter is inserted through access holes cut into ductwork. Particles that become airborne through cleaning and are not collected by the vacuum hose are drawn downstream through the duct and removed from the system, preventing their release into occupied spaces.

When air sweeping is utilized, compressed air is introduced to the duct through a hose capped with a skipper nozzle. The compressed air propels the nozzle through the ductwork, dislodging dirt, dust, and debris. The dislodged particles become airborne and are drawn downstream through the duct and out of the system.

A pneumatically or electrically powered rotation bristle brush can be used to loosen dirt, dust, and debris and draw it downstream into a vacuum collector. When dealing with fiberglass ducts or sheet-metal ducts lined with fiberglass insulation, duct-cleaning professionals must take special care to use only specially designed brushes with soft, flexible polymer bristles that remove debris without putting extra stress on surfaces.

CONCLUSION

An HVAC system with ductwork that is properly sealed, well insulated, and well maintained is an excellent defense against poor IAQ in buildings. When more attention is given to efficient duct designs, building and design professionals can produce more sustainable buildings with occupants who are healthier, more comfortable, and, therefore, more productive.

REFERENCE

-

NAIMA. (2002). Insulation facts 34: The facts about mold growth. Alexandria, VA: North American Insulation Manufacturers Association.

A product manager with CertainTeed Corp.'s HVAC group, Ken Forsythe previously worked at Alcoa and Ford Motor Co. He received a bachelor's degree in mechanical engineering from the University of Toledo and a master's degree in business administration from the University of Michigan. He can be contacted at [email protected].