In recent years, great strides have been made in the reduction of HVAC-system energy consumption. Chillers have become much more efficient at both part and full load. Low-flow, high-delta-T chilled- and condenser-water systems have optimized overall chilled-water-plant efficiency. Energy-recovery devices have become more mainstream. Terminal conditioning approaches are more efficient than ever.

With these improvements, fan energy consumption has become a bigger part of overall system energy consumption. If the impressive trend in energy-use reduction is to continue, we must focus on minimizing fan energy. The intent of this article is to identify and demonstrate methods of minimizing HVAC-system fan energy consumption. Much of the article focuses on minimizing fan horsepower through reduction in system pressure drop, but fan selection and control strategies are touched upon as well.

The Cost of Air Friction

Before getting into methods of reducing fan horsepower (and corresponding energy use/cost), it is important we get our arms around the penalty associated with pressure drop.

For example, what is a reduction in pressure drop of 0.75 in. wc worth? Looking at it per 10,000 cfm, the fan-horsepower equation is:

P = Q × DP ÷ (6,356 × EffFan)

where:

P = mechanical brake horsepower, excluding drive or motor losses

Q = airflow, cubic feet per minute

DP = pressure drop, inch water column

EffFan = mechanical fan efficiency

Assuming mechanical fan efficiency of 60 percent:

P = 10,000 × 0.75 ÷ (6,356 × 0.60) = 1.97

Considering a system of this size typically has a fan in the 10-to-15-hp range, this savings is significant.

Filters

Several components of air-handling and air-distribution systems contribute significantly to overall system pressure drop. In some cases, designers have choices that allow them to meet design objectives while minimizing system pressure drop. Take filters, for instance. One, of course, first needs to decide the level of filtration required. This decision is not to be taken lightly, as it will affect pressure drop significantly.

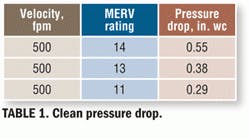

Table 1 shows clean-pressure-drop data for one manufacturer’s cartridge-filter line. Table 2 shows midlife pressure drop for the same filters, assuming filter changes at twice the clean pressure drop.

The decision to use MERV (minimum efficiency reporting value) 14 filters instead of MERV 13 or MERV 11 filters comes at a cost of 0.26-in.-wc or 0.39-in.-wc pressure drop, respectively. By no means is this to suggest less filtration than is required should be provided. It simply is to suggest that filter selection is not always a cut-and-dried decision, and one should consider pressure drop in addition to MERV level and dust-holding capacity.

Various forms of active and combination active/passive filtration offer rather low pressure drop for a given MERV rating. For a MERV-NC (MERV testing using non-conductive dust, as opposed to carbon black) rating of 15, one manufacturer of combination active/passive filtration systems claims a clean-filter pressure drop of less than 0.3 in. wc without prefilters. Depending on the combination of pre and final filters used, this could represent a savings of 0.6 in. wc clean and 0.9 in. wc midlife, compared with a pleated pre/cartridge final-filter combination. Of course, there is much more than media to consider when choosing filtration, but if we keep pressure drop in mind, we will consider a wider range of filtration technologies.

Coils and Bypass

Of course, coils and energy-recovery devices make up a significant portion of system pressure drop. In many cases, there are significant operating hours during which a coil or energy-recovery device is inactive. It is not uncommon for a cooling coil to have a pressure drop of 0.6 in. wc and be inactive for most of the year. Energy-recovery devices can have pressure drops of 0.6 in. wc to 1.0 in. wc on each side (supply and exhaust) of a system. When an energy-recovery device is inactive, much of the pressure drop can be “bought back” with an air-side bypass. With a bypass that operates at 0.1 in. wc not requiring much space, savings of 0.5 in. wc in the case of a cooling coil and 1.0 in. wc to 1.8 in. wc in the case of an energy-recovery device are possible.

Another approach is to reduce the number of coils through the use of combination coils. For example, consider an air-handling unit for a laboratory (100 percent outdoor air). Typically, there will be a need for energy recovery, preheat, and cooling. While these functions certainly can be provided with three separate coils (with corresponding pressure drop), perhaps two functions (e.g., energy recovery and preheat) can be provided with one coil. If that can be done, significant pressure-drop savings can be had.

Terminal Flow-Control Devices

With certain types of flow control, the greater the pressure drop, the greater the controllability, but, of course, that comes at the price of additional fan horsepower. There are ways, however, to achieve precise control while reducing pressure drop. For example, the standard product line from one manufacturer of precision airflow-control valves for laboratory applications has a minimum pressure drop of 0.6 in. wc. This same manufacturer offers a modified product line with a minimum pressure drop of 0.3 in. wc (for a net savings of 0.3 in. wc). Alternatively, other manufacturers offer precision airflow-control valves with pressure drops of less than 0.3 in. wc. Of course, a comparison of devices must include consideration of more than pressure drop (e.g., controllability, accuracy, flexibility), but the differences in pressure drop are large enough to warrant serious consideration.

Static-Pressure Reset

Static-pressure reset is an excellent method of reducing fan energy in variable-volume systems with terminal control devices (e.g., commercial and laboratory variable-air-volume systems). A direct-digital-control (DDC) system continually polls the digital controllers of terminal flow-control devices, looking for the most-open device. Then, the DDC system adjusts slightly downward the static-pressure setpoint (supply or exhaust) in the air-handling system and polls the terminal devices again. This continues until the most-open device is nearly (to provide a margin of safety and controllability) wide open. This leads to lower average pressure in the system and reduced average fan horsepower and associated energy costs. An added benefit is reduced average noise levels because of lower pressure drop across the terminal devices.

Contrast this with the more traditional approach of having a constant static-pressure setpoint. Most of the time, the setpoint will be much higher than necessary, with the extra static “wasted” by the terminal control devices.

It is important to note that for static-pressure reset to work, a DDC system must be “knowledgeable” of the positions of terminal devices. Otherwise, it has no practical way of knowing whether it went too far in reducing static-pressure setpoint.

Choosing the Right Fan

Now that we have done the best we can to reduce system pressure drop, it is time to make the wisest possible choice of fan. This is a deep and extensive topic, one well beyond the scope of this article. There are, however, some simple points to make:

- Give serious consideration to variable-speed fans, even for constant-volume applications. Often, a constant-speed fan is balanced to the proper flow by increasing system pressure drop via the closing of balancing dampers. This leads to a higher-than-necessary permanent fan horsepower. Belt-drive fans can be adjusted through the changing of sheaves, but, often, this is inconvenient enough that it does not happen. Much more convenient and, thus, much more likely to happen is the adjustment of fan speed to match the flow/pressure requirements of a system.

- Consider direct-drive, as opposed to belt-drive, fans. Direct-drive fans do not experience drive losses, as belt-drive fans do. Additionally, the maintenance costs of direct-drive fans are lower.

- Consider electronically-commutated-motor- (ECM-) driven fans. Brushless, direct-current ECMs typically have better full- and part-load efficiencies than their alternating-current counterparts. ECM fans nearly always are direct-drive and are available in relatively small capacities.

Energy-Recovery Devices

In any evaluation of the viability of energy recovery for a project or comparison of energy-recovery technologies, pressure drop is important to consider. Like anything else, gains in one area can be offset by losses in another. For example, the energy-recovery effectiveness of a plate heat exchanger can be increased by increasing plate area, but this will be accompanied by an increase in pressure drop. At some point, the increased effectiveness is more than offset by the pressure drop, and there is no point in pushing further. In other words, there is an energy-recovery “sweet spot” for a device.

The parasitic losses associated with air-side pressure drop in energy-recovery systems are significant. Failure to consider them will lead to a gross overstatement of the financial benefits of a device.

Summary

When designing an HVAC system for minimum energy use, one should:

- Understand the cost of pressure drop.

- Choose the appropriate level of filtration and the technology that will achieve the air-cleaning objective with minimal pressure drop.

- Provide bypass paths around coils inactive for significant periods.

- Combine coils, when possible.

- Choose terminal flow-control devices that meet control objectives while minimizing pressure drop.

- Choose fans wisely, giving preference to variable-speed, direct-drive arrangements.

- Consider pressure-drop implications when choosing an energy-recovery technology.

Follow these guidelines, and you, your clients, and the environment will benefit.

Scott Smith, PE, is vice president of Accuspec Inc., a manufacturer’s representative specializing in airflow-movement and control products for critical environments. He has a bachelor’s degree in electrical engineering from Rutgers; has completed HVAC training courses at the Johnson Controls Training Institute in Milwaukee and through Carrier Corp. in Syracuse, N.Y.; and holds certification in air and hydronics balancing from the National Environmental Balancing Bureau. He is an active member of ASHRAE and president-elect of its New Jersey chapter.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].