Buildings are not created to use energy, but to provide healthy and productive indoor environments. However, efforts to save energy may cause a reduction in health and productivity by degrading indoor-air quality (IAQ). Therefore, maintaining buildings that provide healthy and productive indoor environments requires testing and measuring of key IAQ parameters. As often is said, if you do not measure energy, you cannot manage it — the same is true for ventilation performance.

IAQ-MEASUREMENT GOALS

Because IAQ can be considered a function of the interaction of contaminant sources and the effectiveness of ventilation utilized to dilute and remove air contaminants, measurement goals include assessing the source strength of air contaminants and determining the amount of ventilation provided to occupants. While contaminant sources in furnishings and finishes may be reduced through careful administration of maintenance operations, people-related sources, such as shed cold and flu viruses, always will be a concern. This makes the continual assessment of the actual amount of ventilation provided the most important aspect of achieving a healthy indoor environment.

The monitoring of ventilation performance also is important for energy conservation. Many building-energy conservation efforts will be able to decrease the amount of energy required to provide thermal comfort because of improvements in the thermal performance of building envelopes and lighting efficiencies. The energy required to condition outdoor air for ventilation will become a larger percentage of the energy consumed in ongoing building operations.

Continually assessing ventilation performance requires monitoring of the combined result of an HVAC system's components to ensure they achieve the intended amount of ventilation. Just assessing the quantity of outdoor air entering an HVAC system's intake does not show how much air is delivered to building occupants. Although the quantity of outdoor air entering an HVAC system may be enough to ventilate a building generously, imprecise distribution may not deliver ventilation to occupied building zones. Just as the ultimate result of a building's performance depends on the interaction of design decisions, operational performance depends on how the different aspects of a building and HVAC system work together. Therefore, it is necessary to conduct an integrated performance assessment over the life of a building.

The IAQ measurement approach that this article will address is the monitoring of carbon-dioxide (CO2) concentrations at the periphery of an occupied space. People are a significant source of this gas, and its generation rate is far more predictable than any of the other bioeffluents generated by humans. The CO2 concentration in one exhaled breath is about 40,000 ppm, which is 100 times greater than the 400 ppm found in relatively clean outdoor air. CO2 concentrations measured at the periphery of an occupied space reflect the dynamic interaction between occupancy conditions and ventilation effectiveness.

Occupancy conditions include the number of people present, their metabolic activity levels, and how long they have been present in a space. Ventilation effectiveness includes how rapidly occupant-generated bioeffluents are diluted and removed.

VENTILATION RATES

The minimum recommended ventilation rates listed in American National Standards Institute (ANSI)/American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 62.1, Ventilation for Acceptable Indoor Air Quality, are based merely on perceived comfort among occupants and are not defined as achieving the healthiest indoor environment. According to ANSI/ASHRAE Standard 62.1, IAQ is defined as acceptable if the indoor air contains no known contaminants at harmful concentrations as determined by cognizant authorities and if a substantial majority (80 percent or more) of the people exposed to the air do not express dissatisfaction.

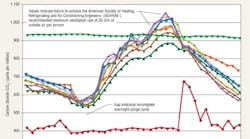

Sometimes, however, even this ASHRAE-recommended minimum ventilation rate is not achieved. As shown in Figure 1, an overzealous effort to save energy in an office building resulted in localized ventilation deficiencies. In this shared-sensor-monitoring approach, all of the CO2 concentrations values are measured with the same sensor. Air samples are drawn to a central location by a vacuum pump, computer control, and sampling-line network.

Using the difference between indoor and outdoor CO2 concentrations, a ventilation rate can be determined. For example, the FAS No. 2 location in Figure 1 has a peak indoor value of 1,050 ppm and an outdoor value of 410 ppm, resulting in a ventilation rate no greater than 16.5 cfm per person. In a situation in which it cannot be determined if equilibrium conditions were achieved before people started leaving for the day, the actual ventilation rate might be lower. Despite the uncertainty of the actual ventilation rate, it is clear that the ASHRAE-recommended minimum ventilation rate of 20 cfm per person was not being achieved. What also can be observed in this CO2 data plot is that the operation of the HVAC system was not effective in achieving a complete overnight purge, as a residual level of CO2 remained in the building the morning of reoccupancy.

The dampers controlling the outdoor-air percentage were readjusted, and an assumed value of 20 percent was dialed in, resulting in the CO2 monitoring data shown in Figure 2. With this larger amount of outdoor air in the supply air, early morning residual bioeffluents from the previous day's occupancy, as well as peak CO2 values observed in the building, were reduced, indicating that a much healthier indoor environment was being achieved.

HEALTHY INDOOR ENVIRONMENTS

A study focusing on the healthfulness of indoor environments1 found that exceeding ASHRAE-recommended minimums achieved reductions in short-term absentee rates. The study reported that the cost of providing additional ventilation was more than offset by the savings resulting from reduced sick leave. In fact, it noted that the recommended levels of outdoor-air supply may be associated with significant morbidity and lost productivity. On a national scale, this could cost as much as $22.8 billion per year.

Another study2 reported that a 1-percent increase in productivity in an average office building could justify a doubling of the building's maintenance and energy budgets. This result stems from the fact that people-related costs, typically about $300 per square foot, far exceed energy costs, about $3 per square foot.

These problems lead to an important question: Is the intended amount of ventilation actually being achieved? Accurately monitoring and reviewing CO2 concentrations in an occupied space and comparing them with outdoor conditions can provide an answer. In addition to this diagnostic determination, monitoring concentration percentages can be used to automatically adjust the amount of ventilation provided in variable-occupancy locations. This technique is called demand-controlled ventilation (DCV).

While more buildings are starting to include CO-2monitoring equipment, they are not necessarily achieving the potential benefit that can accrue from this investment. Steps need to be taken so that accurate ventilation-performance data are collected and reviewed and ventilation performance can be fine-tuned to achieve a healthy balance between indoor environmental quality and energy use. As stated earlier, if you are not measuring ventilation, you cannot expect to manage it. Conversely, if you want to do a good job of managing energy, you need to do a good job of measuring it.

MEASURING AND MANAGING ENERGY

Achieving this full benefit involves several important steps, including appropriate placement of CO2 sensors, proper monitoring methods, suitable calibration procedures, and a timely review of CO2-monitoring data.

The biggest error in the placement of CO2 sensors is locating them too far from occupied areas. When this occurs, sensors typically are placed in the return airflow at an air-handling unit (AHU). By measuring the air at this location, a ventilation-performance assessment at best reflects an average of the conditions in the locations from which the air is returning. In addition, as pointed out in ASTM Standard D6245-2002, Standard Guide for Using Indoor Carbon Dioxide Concentrations to Evaluate Indoor Air Quality and Ventilation,3 sampling in the return airflow allows for the possibility that the supply air will short-circuit to the return, resulting in a low CO2 concentration in the return air relative to the occupied portion of the space.

Measuring air too close to occupants also can be a problem. The inclusion of even a small portion of a concentrated exhaled breath can erroneously indicate a ventilation deficiency. Therefore, it is recommended that this parameter be measured at the periphery of an occupied space.

Two methods of CO2 monitoring are available: distributed individual sensors and the more accurate shared-sensor approach. The accuracy of the use of individual sensors was called into question in a paper published by Lawrence Berkeley National Laboratory,4 which stated that the accuracy of CO2 sensors in commercial buildings frequently is less than is needed to measure peak indoor/outdoor CO2-concentration differences with less than 20-percent error. Ventilation rates are measured more accurately with a shared-sensor approach because measurements are based on the difference between indoor and outdoor CO2 disparities. Further, the same sensor is used for the indoor and outdoor locations, rather than different sensors that might have various errors associated with them.

In addition to the continuous ventilation-performance commissioning that can be achieved with CO2 monitoring, dew point should be assessed constantly. This information provides diagnostic feedback that assesses the effectiveness of a building's moisture management. Checking on moisture-management performance includes assessments of dehumidification and humidification operations, as well as the identification of localized elevated humidity caused by outdoor water intrusions or indoor water leaks.

Expected dehumidification may not be achieved because the chilled-water flow to a cooling coil may be restricted. However, localized humidification can be assessed by examining a plot comparing dew points at multiple monitoring locations. Monitoring dew points also can serve as an early warning system to rapidly identify the presence of elevated moisture levels in a building, which can be caused by a leak in the building envelope or plumbing. Early detection can help prevent uncontrolled mold growth.

Airborne-particulate concentrations also should be measured periodically to assess another aspect of IAQ conditions. One key thing to consider when assessing airborne-particulate concentrations is that much of a building's particulate matter comes in with, and is generated by, the building's occupants, not its HVAC system. Therefore, even if the HVAC system has filters with high Minimum Efficiency Reporting Values and its ductwork has been cleaned recently, there still may be elevated particulate levels in the air being breathed in by the occupants because of their presence and activities.

According to a document on cleanroom protocol,5 the particle-generation rate of a person standing motionless is 100,000 per minute in the 0.3-micron-and-larger size range. For a person walking at 2 mph, the particle-generation rate jumps to 5 million per minute in the 0.3-micron-and-larger size range.

Another aspect of IAQ measurement is assessing any volatile organic compounds (VOCs) that are present. Unfortunately, this can be difficult. Real-time measurement tools, such as photoionization detectors, merely are generalized VOC sensors, and their results are difficult to interpret. More accurate VOC determinations, such as laboratory analyses of pre-evacuated polished-aluminum canisters or sampling media, tend to be expensive and yield results only for a limited space and time. The most cost-effective approach may be to review whether occupant-generated bioeffluents are being diluted effectively and removed overnight. If this is not occurring, then the VOCs probably are not being diluted and removed effectively.

CONCLUSION

The bottom line regarding measuring parameters to improve IAQ while minimizing the associated energy use comes down to maximizing the quality of the data monitoring of ventilation and moisture-management performance. In many buildings, this is best achieved by installing a shared-sensor monitoring system that measures CO2 concentrations and dew-point temperatures and having these IAQ-related measurements reviewed in a timely fashion.

Just as more people are realizing the benefits of integrated design, integrated performance assessments that consider how all of the components of a building and its HVAC system work together to achieve a healthy and productive indoor environment are needed.

REFERENCES

-

Milton, D., Glencross, M., & Walters, M. (2000). Risk of sick leave associated with outdoor air supply rate, humidification, and occupant complaints. Indoor Air, 10, 212-221.

-

Fisk, W.J., & Rosenfeld, A.H. (1997). Estimates of improved productivity and health from better indoor environments. Indoor Air, 7, 158-172.

-

ASTM. (2002). Standard guide for using indoor carbon dioxide concentrations to evaluate indoor air quality and ventilation. ASTM D6245-2002. West Conshohocken, PA: ASTM International.

-

Fisk, W., Faulkner, D., & Sullivan, D. (2006). Accuracy of CO2 sensors in commercial buildings: A pilot study. Berkeley, CA: Lawrence Berkeley National Laboratory.

-

EE407 introduction to microfabrication: Clean room protocol. (n.d.). Retrieved from www.coe.montana.edu/ee/tjkaiser/ee407/notes/EE407-03CleanroomProtocol.pdf

David W. Bearg, PE, CIH, holds a bachelor's degree in chemical engineering from Northeastern University and a master's degree in environmental health sciences from the Harvard School of Public Health. An accomplished author and speaker, he wrote the book “Indoor Air Quality and HVAC Systems.” He can be contacted at [email protected].