Design Guidelines for Stratification in UFAD Systems

Editor’s note: This is the first of two articles based largely on work being conducted under a research grant from the California Energy Commission, with additional funding from the Center for the Built Environment, to develop software for calculating the energy performance of underfloor-air-distribution systems. The companion article—“Design Guidelines for Underfloor Air-Supply Plenums” by Fred S. Bauman, PE; Tom Webster, PE; and Hui Jin—will be published in the July issue of HPAC Engineering.

The control of room-air stratification is critical to the design and operation of successful underfloor-air-distribution (UFAD) systems, representing an oftentimes complex balancing act: Increasing stratification by reducing airflow or mixing for a given space heat load saves energy, while decreasing stratification by boosting airflow or mixing for a given space heat load improves occupant comfort.

The Center for the Built Environment (CBE) has conducted full-scale laboratory experiments to study the impact of stratification in interior and perimeter office spaces. Because the findings cover topics that are of considerable interest to the industry at this time, the following interim guidelines are offered. Each of the topics outlined in this article require more research for specific guidance to be offered. For a more complete overview of UFAD design requirements, see “Underfloor Air Distribution (UFAD) Design Guide”1 and the Underfloor Air Technology Website (www.cbe.berkeley.edu/underfloorair).

ROOM-AIR STRATIFICATION

In this article, all systems—interior and perimeter— are assumed to operate under a variable-air-volume (VAV) control strategy.

Interior zones. Stratification is the result of complexinteraction between thermal plumes generatedby heat sources and turbulent airflow from floordiffusers. The height above the floor to which themixing provided by diffusers occurs—termed the“occupied zone” (OZ)—is limited. What’s more,the mixing process is less than perfect, as stratificationexists both in the OZ and above. The type andnumber of diffusers can have a significant impacton stratification in the OZ.

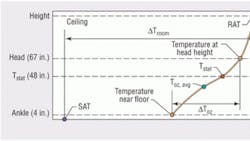

Figure 1 illustrates two key temperature differences:

• Overall difference between return- and supply-air temperature (ÄTroom), which can be used, in combination with total room-airflow rate, to calcu- late the fraction of total room heat gainbeing removed by entering and leavingairflow (heat-extraction rate). Withconventional-air-distribution (CAD)(i.e., overhead) mixing systems, heat-extractionrate typically is equal to thesum of all of the load components ina space, allowing easy calculation ofrequired design cooling airflow. With UFAD systems, however, radiant heat exchange plays a role in determining the overall energy balance in a space. This, plus additional conduction heat exchange, results in a significant amount of energy being transferred from spaces to supply plenums, particularly in multistory buildings. For a given load, ÄTroom and room airflow primarily are determined by thermostat setting, supply-air temperature, and diffuser throw characteristics.

• OZ delta-T (ÄToz), which is a function of the vertical temperature gradient and plays an important role in determining comfort conditions. Comfort conditions (in stratified systems, to first order) are a function of OZ average temperature (Toz, avg [Figure 1]), ÄToz (not to exceed 5 F by American Society of Heating, Refrigerating and Air-Conditioning Engineers [ASHRAE] standards,2 although current research3 indicates that that may be conservative), and floor temperature (in addition to air velocity and relative humidity).

Current CBE research indicates that stratification profiles are influenced by the throw characteristics of diffusers. Figure 2 shows room-stratification profiles for an interior zone with varying numbers of swirl diffusers operating at constant load and total room airflow. Adding diffusers at constant room airflow reduces the airflow per diffuser and, thus, throw height, leading to more stratification in the OZ. Throw characteristics are indicated by diffuser design ratio (DDR), the ratio of actual airflow per diffuser to recommended design flow. For swirl diffusers, to first order, the less airflow delivered by a diffuser (the lower the DDR), the lower the throw height. Research indicates that swirl diffusers have more potential to produce low throw (which, in turn, may produce greater OZ stratification) than variable-area diffusers (photos A, B, and C). Variablearea diffusers produce a relatively consistent stratification profile because of their consistent throw height over a broad range of operating conditions.

In stratified environments, all of the aforementioned factors interact and need to be considered when determining the airflow and number of diffusers for a given design comfort condition. Research suggests, however, that under VAV control, a stratification profile may remain relatively constant as load changes, as shown in Figure 3. This finding is the subject of further investigation because it is based on a small number of tests.

Perimeter zones. Perimeter zones differ from interior zones in type and magnitude of heated thermal plumes. In perimeter zones, the dominant plume occurs vertically at windows, and, under peak load conditions, the heat gain is two to three times total internal gains. This creates a forceful plume with somewhat different characteristics than internal load plumes. However, the impact of the interaction with floor-diffuser airflows is much the same. Thus far, CBE research has identified four important issues:

• Stratification is significantly greater with blinds closed than with blinds open. With blinds closed, the overall room-temperature difference approaches that of CAD systems, as shown in Figure 4. Figure 4 also shows the effect of reducing the vertical throw of linear diffusers. This was accomplished by increasing the number of diffusers from eight to 10 and decreasing the angle of the discharge vanes from 90 degrees to 53 degrees.

The use of blinds at peak load has profound implications, with considerable difference of opinion among practitioners about whether to assume blinds are open or closed for design loads. Recent CBE research4 indicates that blinds often are closed at peak conditions because of the impacts of direct radiation and glare on comfort. Still, some designers feel the assumption that occupants will close blinds during peak conditions is too risky.

• Stratification can be increased by using lower-throw diffusers, but care must be taken to maintain acceptable comfort conditions in the OZ. Further research is needed to determine how important a factor this is, especially when blinds are closed.

• Some designers believe that placing return diffusers near windows will help “siphon off ” warm air and reduce the load in a space. The authors’ limited research (not shown here) suggests that is not the case. The placement of ceiling return grilles near windows appears to have little effect on stratification performance.

• To offset the effect of a greater mean radiant temperature in perimeter spaces, the control set point can be adjusted with consideration of stratification to yield an appropriate average OZ temperature.

ZONING CONSIDERATIONS

Zoning above a raised floor is important to occupant comfort. How the zones are serviced dictates the support needed in the supply plenum. Above-floor zone types generally fall into one of the following categories:

• Open plan, interior.

• Open plan, exterior.

• Private office, interior.

• Private office, perimeter.

• Special spaces (e.g., conference rooms, utility rooms, etc.).

There is considerable debate regarding the need to subzone interior open-plan areas because of the difficulty maintaining significantly different temperature conditions in adjacent open-plan spaces. Outside of the area immediately around floor diffusers (the clear zone), temperature profiles are quite consistent. Additionally, the variability of interior zone loads depends on the type of occupancy. Many UFAD projects appear successful with only one large open-plan zone controlled by averaging room-thermostat readings. Sometimes, even interior private offices are included in this global zoning, with occupants relied on to adjust floor diffusers to modify the environment to their needs. Usually, each special space (and group of private offices, if necessary) is controlled as a separate zone.

Generally, subzones are created with passive diffusers serviced by an equivalent plenum zone—a section of the plenum that is partitioned off and provided with independent pressure controls—below the floor or damper-controlled diffusers using constant plenum pressure, which allow an open, unrestricted plenum. Either option supports independent temperature set points and options for off-hour control on a zone-by-zone basis.

The same solutions generally apply to perimeter open-plan areas, private offices, and special spaces, the primary difference being that private offices usually are grouped to form zones. The maximum size of perimeter zones usually is dictated by equipment-capacity limitations.

In general, open plenums are preferred because they are less expensive to install and offer fewer restrictions. For interior zones, this suggests that either a single zone or damper-controlled diffusers be used. Whether an open or a zoned plenum configuration is used, there will be plenum-air-distribution issues to consider.

ROOM-COOLING-LOAD AND DESIGNAIRFLOW

CALCULATIONS

Room cooling load. The design cooling load for a building with a UFAD system can be calculated in the same manner as the design cooling load for a building with a CAD system: by summing up all of the net design heat gains and transmissions into the conditioned space. However, the determination of design cooling-airflow quantities must take into account key differences between a thermally stratified space produced by a UFAD system and a well-mixed space produced by a CAD system. A simplified, practical procedure for determining cooling-airflow requirements for a UFAD system is one of the design community’s most frequently stated needs (and the subject of a new CBE research project). Until such a tool is available, the following guidance is offered.

Distribution of loads.With a stratified UFAD system, heat typically is removed from a room through:

• Heat extraction via warm return air exiting at ceiling level.

• Heat entering the underfloor supply plenum by conduction through the slab from the floor below and by radiation and conduction through the raised-floor panels from the room above.

The amount of this heat will have a direct impact on both the amount of air-temperature gain within the underfloor supply plenum and the room design airflow requirements. Therefore, after room cooling load is calculated using traditional methods—and until more-detailed design tools are available—the authors recommend the load be apportioned between the underfloor plenum and the room based on guidance provided in next month’s companion article.

Room airflow, interior zones. To first order, overall system-level load (the total difference between air-handling-unit supply temperature and space return temperature) is assumed to be the same for UFAD and CAD systems. Then, as mentioned above, total UFAD cooling load is split into two components: one to the plenum and one to the room (defined as the combination of room and return plenum). For typical UFAD systems, this appears to result in room loads that are lower than those with CAD systems by just enough to offset the effect of increased supply-air temperature. This conclusion that UFAD airflows are comparable to those of CAD systems is supported by the following:

• Through extensive full-scale testing, the authors investigated room-air stratification over a wide range of UFAD configurations and operating conditions. When the room set-point temperature was maintained at a level similar to that for overhead systems, and stratification did not exceed acceptable limits specified by ASHRAE,2 the measured room airflow rate was similar to the calculated airflow rate for an overhead system with the same cooling load. Additional research is needed to more accurately determine UFAD cooling-airflow rates that will produce in stratified environments comfort conditions equivalent to those of CAD systems.

• Limited experience from completed UFAD installations suggests that, in many cases, cooling-airflow rates are similar to those of comparable overhead installations.

Until more-detailed procedures are developed, a safe recommendation for design airflows for interior space systemcomponent- sizing purposes is to use an equivalent CAD-system airflow rate. Actual airflow rate, however, might be reduced, if stratification is exploited, as indicated in the preceding section.

Room heat gain and airflow, perimeter zones. Preliminary research indicatesthat in perimeter zones, plenum-heatgainproportions are similar to those ininterior zones, suggesting that differencesin ÄTroom and room load will cancel out each other, yielding the same airflow as inCAD. However, when blinds are closed,the ÄTroom for UFAD is increased severaldegrees above the blinds-open case. Thisdelta-T varies with room control setpoint, but is approximately 15-percentgreater.

If blinds are assumed closed, the authors’ preliminary recommendation is to use the room load and airflow calculated for CAD with blinds closed, but decrease the airflow by no more than 15 percent, provided that delivery of 65-F supply air can be assured.

If blinds are assumed open, no credit should be taken for increased ÄTroom, but consideration should be given to using a lower room set point to offset the effects of direct radiation. Further adjustments commissioning process will require further research.

Commissioning considerations. Commissioning is critical to optimizing the performance of UFAD systems, which often are oversized, mostly as a result of the overestimation of design loads. For VAV systems using swirl diffusers, this may result in lower-than-design airflow, which can impact stratification. For VAV systems with variable-area diffusers, the diffusers’ dampers simply will throttle to a more closed position. For these diffusers, somewhat more stratification may be produced by lowering the plenum-pressure-control set point from 0.05 in. wc to, say, 0.03 in. wc.

During commissioning, tests can be performed to determine OZ temperatures during fully loaded conditions. (The authors recommend that this be done with a “stratification-measurement tree” consisting of a string of several sensors monitoring temperature from floor to ceiling.) Prior to stratification measurements, a building should be operated over a long enough period of time (up to a week) to ensure that the thermal mass of the structural slab has been fully charged and is in equilibrium with the daily operation of the building. To date, the use of typical CAD-cooling-thermostat set points of 72 to 74 F has been common. Using these set points with stratified systems could result in an uncomfortable environment for occupants. If measured OZ temperatures are too low because of stratification, the thermostat set point can be increased by 1 to 3 F. This has the added benefit of reducing airflow requirements, which can save fan energy.

If commissioning measurements show that ÄToz is not at least 3 F, then further adjustments (e.g., changing the number of diffusers or plenum-pressure maximum set points) should be made so that the combination of thermostat set point and stratification yields average temperatures in the OZ equivalent to accepted CAD-system values.The development of detailed procedures for this ability to be adjusted after installation.

Proper commissioning is essential for optimizing performance. In this regard, stratification measurements should be made during fully loaded (or close to fully loaded) conditions after a building has been operating for a few weeks. Depending on the outcome of those measurements, thermostat set points, plenum pressures, and/or the number of diffusers can be adjusted.

SUMMARY

In this article, interim design guidance for sizing interior and perimeter zones of UFAD systems was offered. While more needs to be done to develop, substantiate, and extend this guidance, it should result in acceptable performance.

Key points made in the article include:

• Room-air stratification and its implications are fundamental to understanding UFAD-system performance. Diffuser throw characteristics depend on diffuser type and operating conditions.

Besides reducing airflow, lowering diffuser throw for a given load and set point increases stratification. However, some research suggests that under VAV operation, room-air-stratification profiles may remain relatively consistent as load varies.

• Total room heat gain can be apportioned between two major components: the room and the supply plenum. Apportioning total room gains results in room airflows comparable to those of CAD systems. Thus, to first order, UFAD design sizing can be based on CAD room-airflow calculations.

• In perimeter zones, as in interior zones, diffuser throw characteristics impact the amount of stratification. Closing blinds in perimeter zones increases stratification and lowers airflow for a given load and thermostat setting. Designers can exploit this fact and reduce airflow by up to 15 percent by assuming blinds closed for peak loads. If blinds are assumed open, airflows equivalent to those in CAD systems can be used, assuming 63- to 65-F supply temperatures can be maintained.

• Design set points should be considered in light of expected stratification and mean-radiant-temperature environments. Operators may want to consider raising thermostat set points (by 1 to 3 F)—particularly in interior zones—to avoid overcooling.

• UFAD systems are flexible in their can be made during commissioning.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the support of CBE partners Armstrong World Industries; Arup; the California Department of General Services; the California Energy Commission; Charles M. Salter Associates Inc.; Flack + Kurtz; HOK; Pacific Gas & Electric Co.; Price Industries; RTKL Associates Inc.; Skidmore Owings and Merrill; Steelcase Inc.; Syska Hennessey Group; Tate Access Floors Inc.; the Taylor Engineering Team (Taylor Engineering, The Electrical Enterprise, Guttmann & Blaevoet, Southland Industries, Swinerton Builders); Stantec; Trane; the U.S. Department of Energy; the U.S. General Services Administration; Webcor Builders; York International, a Johnson Controls company; the National Science Foundation; and The Regents of the University of California.

REFERENCES

1) Bauman, F.S. (2003). Underfloor air distribution (UFAD) design guide. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

2) ASHRAE. (2004). Thermal environmental conditions for human occupancy. ANSI/ASHRAE Standard 55-2004. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

3) Zhang, H., Huizenga, C., Arens, E., & Yu, T. (2005, September). Modeling thermal comfort in stratified environments. Paper presented at Indoor Air 2005, 10th International Conference on Indoor Air Quality and Climate, Beijing, China.

4) Inkarojrit, V. (2005). Balancing comfort: Occupants’ control of window blinds in private offices. PhD thesis, Dept.of Architecture, University of California,Berkeley, fall.

Engineering Green

Tom Webster, PE, and Fred S. Bauman, PE, are research specialists with the Center for the Built Environment(CBE) at the University of California, Berkeley. Webster has been engaged in building research and developmen tfor more than 25 years and leads several underfloor-air-distribution (UFAD) projects, while Bauman leads the CBE’s research program on UFAD and is the author of “Underfloor Air Distribution (UFAD) Design Guide,” published by the American Society of Heating, Refrigerating and Air-Conditioning Engineers in 2003.