Improving IAQ With Liquid-Desiccant Dehumidification

Commercial and industrial HVAC systems represent a large portion of U.S. energy consumption. According to the U.S. Environmental Protection Agency (EPA), buildings are responsible for 39 percent of total U.S. energy use and 68 percent of total U.S. electricity consumption. The EPA has predicted that energy and electricity demand in the United States will increase by 31 percent and 40 percent, respectively, within the next 25 years. The current economic situation and a worldwide desire to be green dictate a continued effort to reduce energy and utility consumption. This article will discuss how liquid-desiccant total-enthalpy-recovery systems can help fulfill those goals.

ENTHALPY-RECOVERY OPTIONS

The two basic types of air-to-air enthalpy-recovery systems are sensible heat and total enthalpy. Sensible-heat devices, such as heat wheels, heat pipes, flat-plate exchangers, and coil loops, transfer only temperature among ventilation and exhaust air streams. Total-enthalpy devices, such as enthalpy wheels and liquid-desiccant systems, transfer temperature and moisture among air streams.

However, enthalpy wheels cannot offer all of the benefits of liquid-desiccant total-enthalpy systems. Associated with rigid ductwork and seals that allow cross-contamination, enthalpy wheels experience frosting in cold climates. Not subject to cross contamination or frosting, liquid-desiccant total-enthalpy systems are known for flexible installation layouts and reducing the installed size of ancillary air-handling equipment.

Total-enthalpy devices can achieve greater energy savings than sensible-heat devices. In comfort-conditioning applications, total-enthalpy devices generally save about three times as much energy during summer and 20 percent more energy during winter.

Total-enthalpy-recovery systems utilize energy previously lost to the environment. Enthalpy wheels and liquid-desiccant systems can have a peak design of 65 percent of the total energy used. This amount is not altered much during off-peak conditions. The energy available plays the largest role in total savings.

Practical for facilities that require significant ventilation, such as office buildings, medical and research facilities, laboratories, and cleanrooms, liquid-desiccant total-enthalpy-recovery systems can save energy while improving indoor-air quality (IAQ) (Table 1). The systems exchange temperature and humidity among ventilation-air streams through a liquid-desiccant enthalpy-transfer solution, providing total enthalpy recovery. The air streams are scrubbed of bacteria, viruses, mold, and other airborne contaminants as they pass through the liquid desiccant, improving air quality. Impurities also are removed from exhaust streams, benefitting neighboring environments. One-hundred percent of the airborne contaminants captured in the desiccant solution are neutralized upon contact.

• No cross-contamination of air streams

Additionally, the system design utilizes separate supply- and exhaust-air modules that are connected only by piping. Because ventilation and exhaust air are handled by separate modules, there is no cross-leakage or microbiological cross-contamination between exhaust air and ventilation air, which can occur with other technologies (see sidebar).

Liquid-desiccant systems offer a cost-effective means of satisfying strict IAQ standards, such as ANSI/ASHRAE Standard 62.1-2004, Ventilation for Acceptable Indoor Air Quality. The recent swine-flu outbreak served as a stark reminder of the need for microbiological protection. Contaminants from the environment can enter buildings through ventilation systems, which can discharge contaminants into the outdoor environment. Liquid-desiccant systems remove microorganisms from interior and exterior air via the desiccant spray's scrubbing effect.

TOTAL-ENTHALPY-RECOVERY TECHNOLOGY

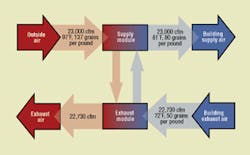

As previously mentioned, liquid-desiccant total-enthalpy systems exchange temperature and humidity among supply- and exhaust-air streams through a liquid-desiccant solution. Air passes through high-efficiency packing material, where it comes in contact with the liquid desiccant. The system's efficiency is driven by the difference between exhaust- and supply-air enthalpy. Utilizing a mechanical eliminator that causes droplet impingement, modern liquid-desiccant systems also incorporate a soft maintainable media to ensure carryover cannot take place.

Enthalpy-recovery systems reduce the utility requirements of air-handling equipment by taking advantage of the enthalpy in a building's exhaust air. During summer, hot, humid makeup air is preconditioned using relatively cool, dry exhaust air. During winter, outside makeup air is preheated/humidified within the liquid-desiccant tower using relatively warm, moist exhaust air from the building and water makeup, if necessary. Because of the bactericidal nature and low freezing point of liquid desiccant, high-pressure steam is not needed to add sterile moisture to air, and frost/freezing is not a concern.

As building designs evolve, demand for fresh air continues to grow, increasing the amount of energy required by air-conditioning systems. Outside-air load represents a substantial portion of total air-conditioning demand. For systems using 100-percent outside air, 50 to 70 percent of the cooling load and 60 to 80 percent of the heating load are impacted by outside air in typical American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) design conditions. For systems using 10-percent outside air, approximately 15 percent of the cooling load and 30 percent of the annual heating load are impacted by outside air (Figure 1).

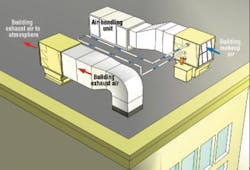

Liquid desiccant enables independent modules that are connected only by piping to handle outside and exhaust air. Separate modules contribute to installation flexibility. Because the modules can be located separately, layouts are adaptable, allowing one piece to be installed on the roof while another is installed in the basement. This reduces the amount of mechanical space required while providing integration with other HVAC equipment. Multiple enthalpy-recovery modules can be used in any liquid-desiccant system, and liquid-desiccant technology can be retrofitted into existing systems (Figure 2).

Best suited for handling fairly large airflows, a single factory- or field-assembled liquid-desiccant system can accommodate flow rates of up to 108,000 cfm. This can reduce installation and maintenance costs significantly. The economical advantage of liquid-desiccant systems is significant in buildings with airflow rates above 10,000 cfm. Recovering 10,000 cfm of air with a dry system would require a 20,000-cfm enthalpy wheel, which would demand a large amount of space. Liquid-desiccant technology further simplifies ancillary air-handling equipment by eliminating the need for humidifiers and accessories.

DESIGN ADVANCEMENTS

Liquid-desiccant systems have been built for more than 70 years. Many design changes have been implemented to improve their performance and reliability.

Any time air passes through a liquid spray, droplet carryover is possible. The most important design consideration for liquid-desiccant systems is the amount of air velocity used around desiccant-sprayed packing material. Because higher velocities reduce the amount of carryover, newer systems have average velocities in the range of 350 to 500 fpm.

Additionally, mist eliminators and screens have been incorporated downstream of the systems' spray section. Eliminator designs and materials have developed significantly; current systems effectively experience “zero discharge.”

CONCLUSION

With increasing energy and electricity consumption, energy efficiency and utility savings are becoming increasingly important issues. Green-building HVAC systems, such as liquid-desiccant total-enthalpy-recovery systems, help control utility costs and provide ventilation enthalpy savings while offering improved IAQ. Typically resulting in a payback period of less than three years, the systems are applicable to green-building and Leadership in Energy and Environmental Design facilities.

SIDEBAR: Air-Purification Abilities

A study conducted by an international science and technology company (available by contacting the author at [email protected]) verifies the air-purification abilities of a liquid-desiccant solution made of lithium chloride.

The agar-plate method was used to investigate bactericidal properties, and the aqueous-suspension test was used to test virucidal potential. The tests exposed selected viruses to the compounds for various amounts of time, followed by quantitation via plaque assay of surviving virus to 5-, 10-, or 20-percent concentrations for 10, 20, or 30 min. Testing demonstrated that:

- There was no measurable transport of bacteria or viruses from one air stream to another.

- Lithium chloride was an effective bactericide at an aqueous concentration of 5 percent weight by volume (w/v) or higher and exposure times of 1 min or longer.

- Lithium chloride exhibited virucidal activity against polio and herpes-simplex viruses at a concentration of 20 percent w/v for a 5 min or longer exposure time.

Peter G. Demakos, PE, is the president of Kathabar Dehumidification Systems Inc., which provides high-efficiency desiccant dehumidification systems for humidity control and energy recovery. He received a bachelor's degree in mechanical engineering from Lafayette College, a master's degree in business administration from the State University of New York at Buffalo, and a master's degree in mechanical engineering from the Massachusetts Institute of Technology.