Wood-Fired Boiler Installed as Part of School’s Green-Energy Initiative

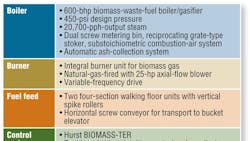

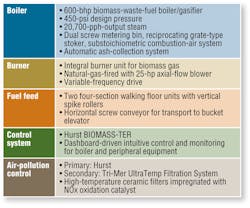

With a goal to have 40 percent of its energy needs met with renewable resources by the end of 2020, The University of Iowa (UI) replaced a natural-gas boiler with a biomass boiler at its Oakdale Research Park campus in Coralville, Iowa. The project was not without challenges, including space restrictions, unusual piping, creative wiring, and many customized solutions worked out in the field.

Biomass Decisions Begin With the Fuel

In 2008, Global Energy Solutions Inc., representing Hurst Boiler & Welding Company Inc., was approached by Ferman Milster, UI associate director, utilities and energy management, to brainstorm a biomass-boiler solution for the Oakdale Research Park plant. The plan was to replace one of four gas boilers with a biomass boiler fired with local fuels, such as wood chips and oat hulls, utilizing an existing coal bunker for fuel storage. The goal was to operate the Research Park campus on 100 percent renewable energy, with fossil fuels in place for backup.

Working with Milster to shape the project were Barry Butler, UI professor of mechanical and industrial engineering and dean of the UI College of Engineering, and Albert Ratner, UI assistant professor of mechanical and industrial engineering. The Oakdale Research Park Boiler System In July 2010, fabrication of the biomass system was approved, and the UI facilities-management team began the collaborative process. Once the equipment was on site, weekly meetings were held to assess progress, discuss necessary adjustments, and sort out responsibilities.

Agricultural-Waste Gasifier

Tied into the biomass-boiler system is a small gasifier provided by Ag Bio-Power LC of Tama, Iowa. The gasifier is used by the College of Engineering for ongoing combustion research and study of alternate, locally obtained renewable fuels, such as expired seeds, corn stover, and paper sludge. Agricultural products introduced into the gasifier produce syngas, which is injected into the burner.

Installation and Startup

According to Bruce Coffee, chief engineer, Hurst Boiler & Welding Co., the UI project required some creative solutions, including modifications to work around space constraints and fixed barriers. Components such as boiler legs, breeching (ductwork), piping, and fly-ash collector chute, were like puzzle pieces that needed to be modified and placed to fit.

Training Is Critical

The training classroom for the project was filled with managers, boiler operators, engineers, and other technicians ready to learn all they could about the new technology. James Alwin, PE, of Global Energy Solutions, who served as a liaison between the university and the various manufacturers throughout the project, attended training sessions as well. According to Alwin, there always is something new to learn about these systems—particularly if a new fuel is being introduced.

Hurst equipment can combust hundreds of different fuels. Reviewing the moving parts, making required adjustments, and performing recommended annual maintenance is essential—even for seasoned boiler technicians.

Recognition

In December 2012, Shive-Hattery, the architect and engineer for the project, was announced as the winner of the Grand Place Award in the Energy Production category in the American Council of Engineering Companies of Iowa’s 2013 Engineering Excellence Awards competition.

For Design Solutions author guidelines, call Scott Arnold, executive editor, at 216-931-9980, or write to him at [email protected].